Vibration measurements of structures

Using PROPAC also time varying surface motions can be measured, since the measurement signal from the complete surface is captured at once by the CCD camera at a specific instance of time. Image blur can be eliminated by reducing the camera shutter-time or by using a pulsed light source for the projection of the patterns. Pulse lasers can be used to achieve pulse durations of only a few nanoseconds. High-Speed cameras and lasers recording rates of some kHz can be used to enable time-resolved deformation measurements of short duration. A typical application of PROPAC for periodic movements is the modal analysis of complex vibrating structures.

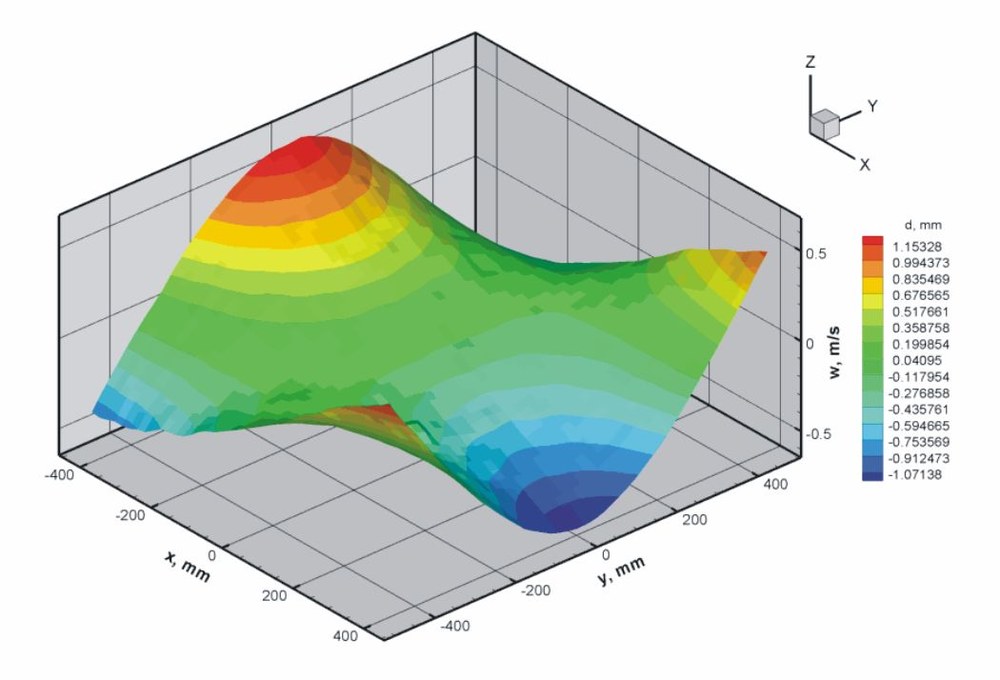

In the following example the modal vibration structures of a flat, vertical hanging plate 0.9 m wide and 1.2 m long are measured with PROPAC, which is carried out at an aluminium honeycomb sandwiched by two aluminium sheets. The pixel resolution of the CCD camera was 1376 x 1040. An exciter is acting perpendicularly on the plate using different positions at the backside. For analyzing vibration modes of structures all trigger signals (camera, laser) were phase-locked to the exciting signal. The frequency of the sinusoidal signal of the exciter is set to a specific resonance frequency of the plate. Then the amplitude signal of the vibrating surface is phase shifted by 90° to the signal of the exciter. The figure shows the result at the resonance frequency of 118.9 Hz. The plate oscillation is characterized by superimposed sinusoidal deformations arising symmetrically to the horizontal and vertical central line of the plate. The surface amplitudes are in the order of 1 mm, whereas the measurement uncertainties are about 20 µm.

This example shows that PROPAC can be applied also to larger surface areas as that of aircraft wings and flaps for example. The advantages of PROPAC are short set-up times and a fast data acquisition, whereas no modifications of the structure and its surfaces are necessary. Using a CCD camera with increased number of pixels the achievable measurement precision can be improved accordingly for a specific size of measurement area. The application of PROPAC is also suitable for smaller measurement areas to get quickly quantitative information of the vibration of complex parts, especially if larger amplitudes occur, e.g. circuit boards with electrical components.