Aeroelastic Experiments

The department “Aeroelastic Experiments” is committed to the planning, realization and analysis of challenging experiments in wind tunnels.

As we look ahead to 2050, a pivotal year for the aviation industry, a significant challenge looms on the horizon: reducing aircraft energy requirements by a staggering 50%. Achieving this goal demands a multifaceted approach, from groundbreaking propulsion concepts to enhancing engine integration within the aircraft system, and, crucially, the development of lighter, more efficient engine components. Yet, in the pursuit of efficiency, we encounter a challenge: the increasing complexity of turbine and compressor blade profiles, resulting in a higher sensitivity to aeroelastic effects such as for example flutter or forced response.

In this blog article, we dive into the world of aeroelasticity and explore how cutting-edge research is contributing to our understanding of these phenomena. At the forefront of this effort is the DLR Institute of Aeroelasticity, which has acquired a remarkable research facility: The Non-Rotating Annular Test Facility.

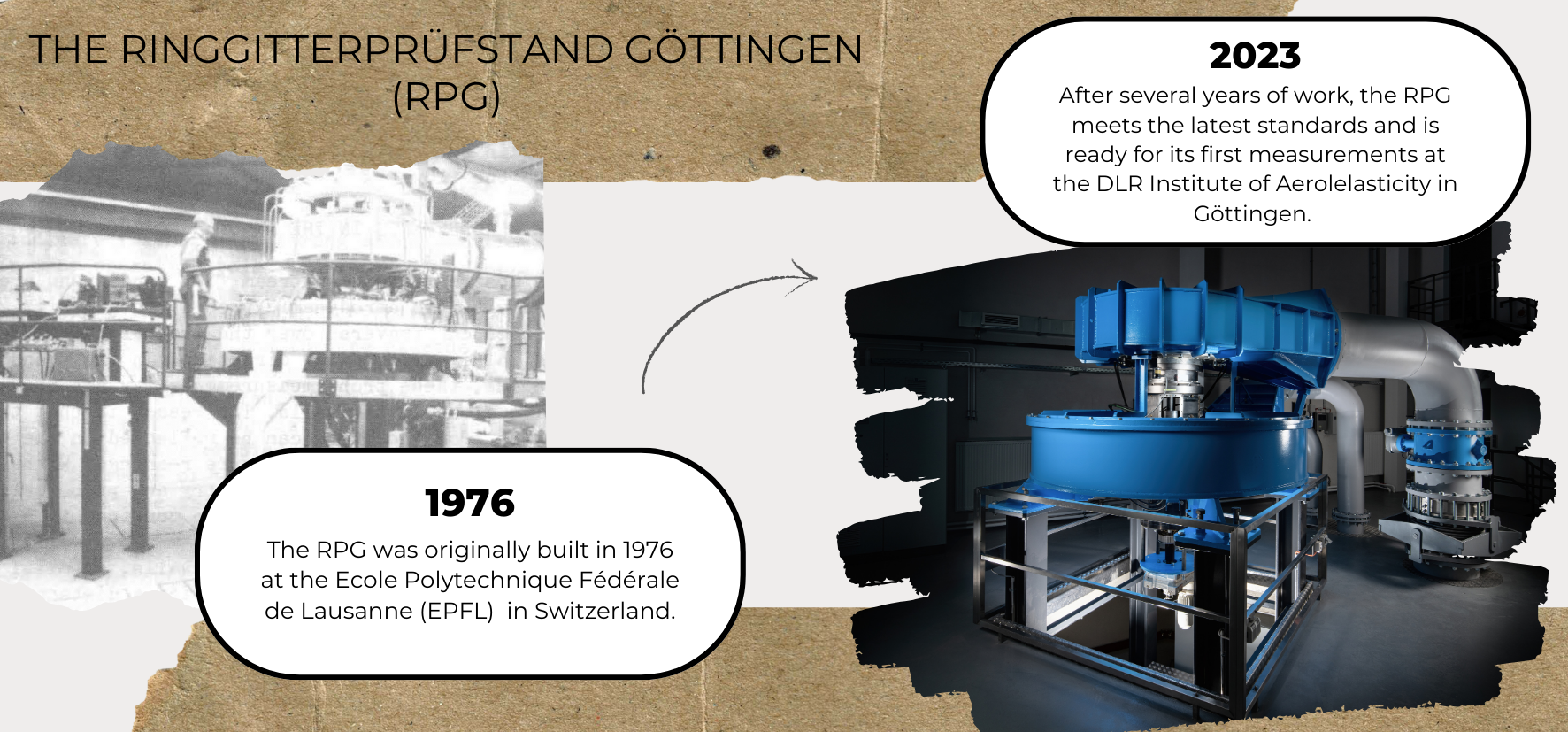

Originally built in 1976 at the Ecole Polytechnique Fédérale de Lausanne (EPFL) in Switzerland, this pioneering test rig has been meticulously updated, integrated into the DLR Göttingen site infrastructure, and rebuilt to meet the latest standards. It's been years in the making, but the effort has been more than worth it. All the pieces of this scientific puzzle have finally come together.

The Non-Rotating Annular Test Facility (Ringgitterprüfstand Göttingen, RPG) stands as a testament to scientific dedication and progress. Designed to delve deep into the aeroelasticity of turbomachinery blades, the RPG offers a unique platform for investigating the complex interaction mechanisms between unsteady aerodynamics and structural dynamics.

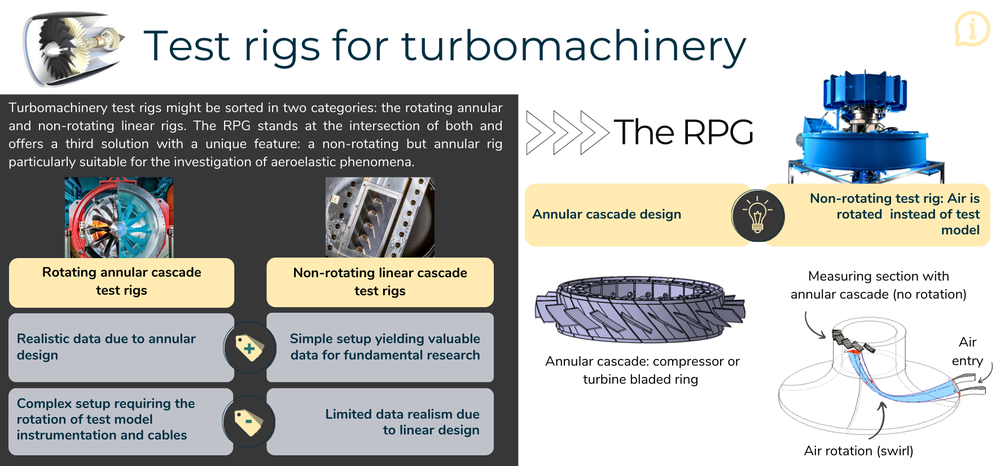

In the world of turbomachinery research, test facilities often fall into two categories: the rotating annular and the non-rotating linear cascade rigs. While the former includes the rotation of the annular test model (typically one or more turbine or compressor rotors, i.e. bladed rings, also called annular cascades) thus providing realistic (scaled) engine data, their complexity, involving also the rotation of the entire instrumentation and cables, poses significant challenges. On the other hand, the latter, non-rotating linear rigs offer significant simplifications. The test model is unfolded into one bladed flat plate (in this case also called linear cascade) where only a few blades are investigated, without rotation. They are valuable for fundamental research but may sacrifice some realism due to the limited number of blades and their linear design.

The RPG stands at the intersection of these two families, offering an adaptable, non-rotating but annular tool for studying various aeroelastic effects. Here, the annular test model representing a turbine or compressor rotor is standing still, while air rotation is induced by a geometrical design at the rig entry. This unique setup allows for intensive rig and model instrumentation and simplified data acquisition.

Key features of the RPG include a 2.4 MW drive motor that propels air in the measuring section of the nozzle, enabling sub-, trans-, and supersonic flow testing. The measuring section has a height of 40 mm, and the annular cascade consists of 20 compressor or turbine blades. Each of these 20 blades is equipped with an independent blade vibration system, allowing for forced excitation measurements. The real treasure lies in the aerodynamic and structural data collected during these experiments. The intricate interplay between the aero- and structural dynamics data can be methodically analyzed. This in-depth analysis yields valuable insights into the blade stability or blade response to an excitation, as well as the phenomena associated to it.

The data collected in the RPG will play a pivotal role in addressing current and future aeroelastic challenges in turbomachinery. This research aims to improve our understanding of flutter, forced response and unsteady flow phenomena, ultimately validating and enhancing the reliability of numerical methods dedicated to aeroelastic predictions. The RPG is also a perfect platform to improve and develop our aeroelastic measurement techniques.

As of now, the team is diligently working on the rig preparation for its inaugural measurements. Anticipation is paramount as we approach the moment when the RPG comes to life. We can't wait to witness this remarkable facility in action and contribute to the propulsion challenges of tomorrow's aviation. Stay tuned for more updates on the game-changing research happening at the RPG.

Dr.-Ing. Virginie Chenaux, DLR-Institute of Aeroelasticity, Department: Aeroelastic Experiments