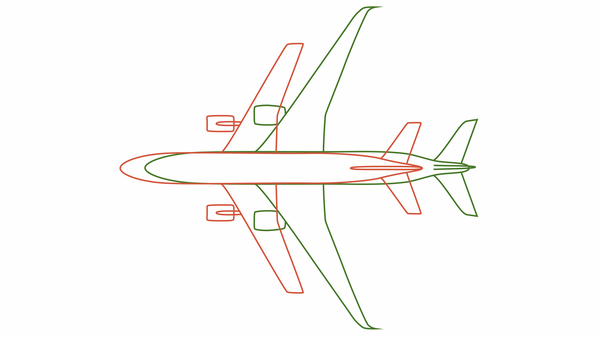

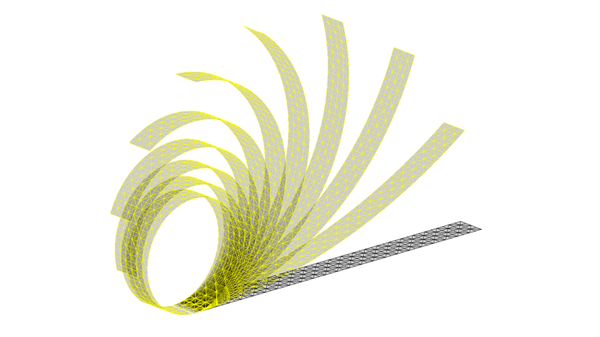

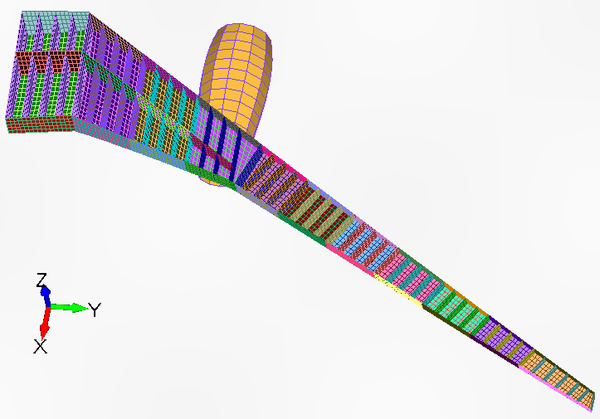

Aeroelastic Design

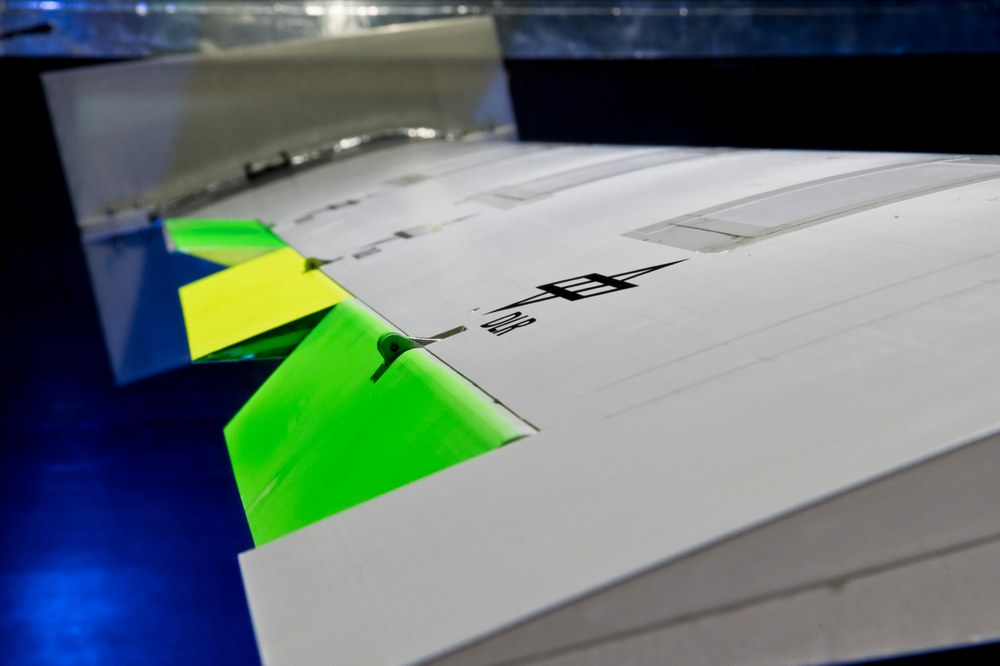

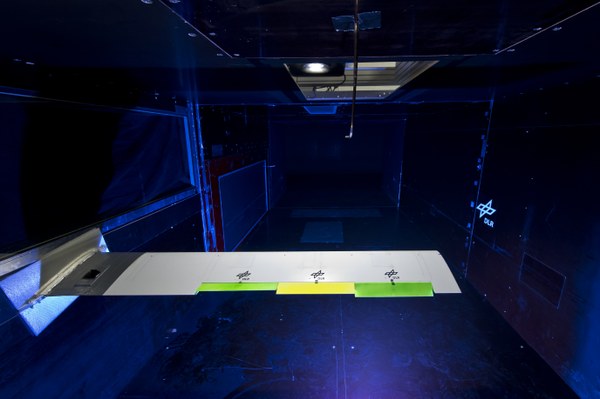

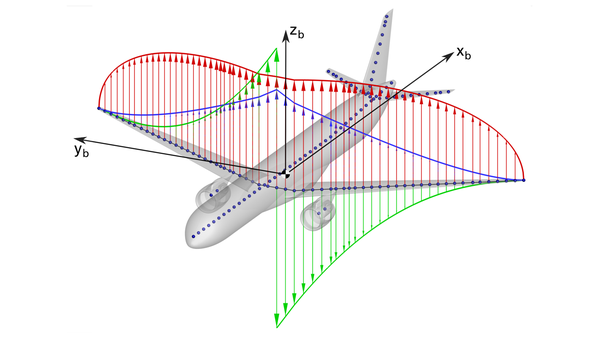

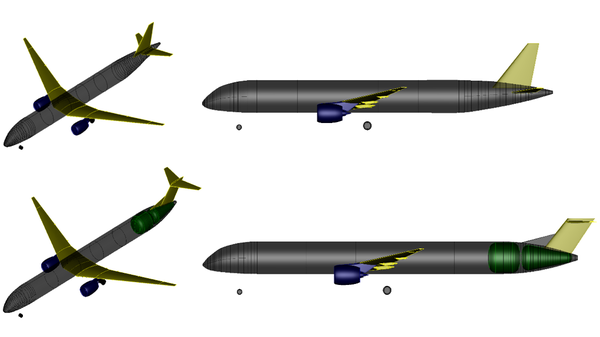

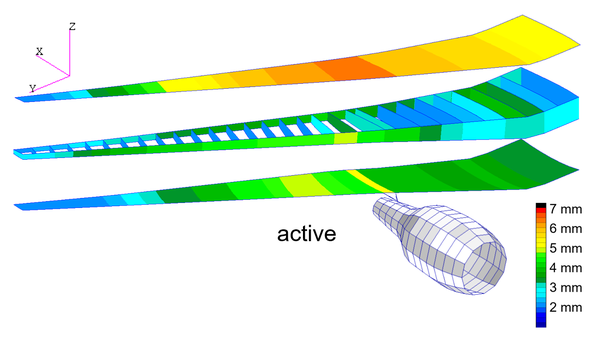

In the research topic of aeroelastic design, we deal with various design tasks in the context of the aeroelastic design of an aircraft, an aircraft component or a wind tunnel model. The development of methods ranges from conceptual design and preliminary design to detailed design for manufacturing, in particular for wind tunnel models.