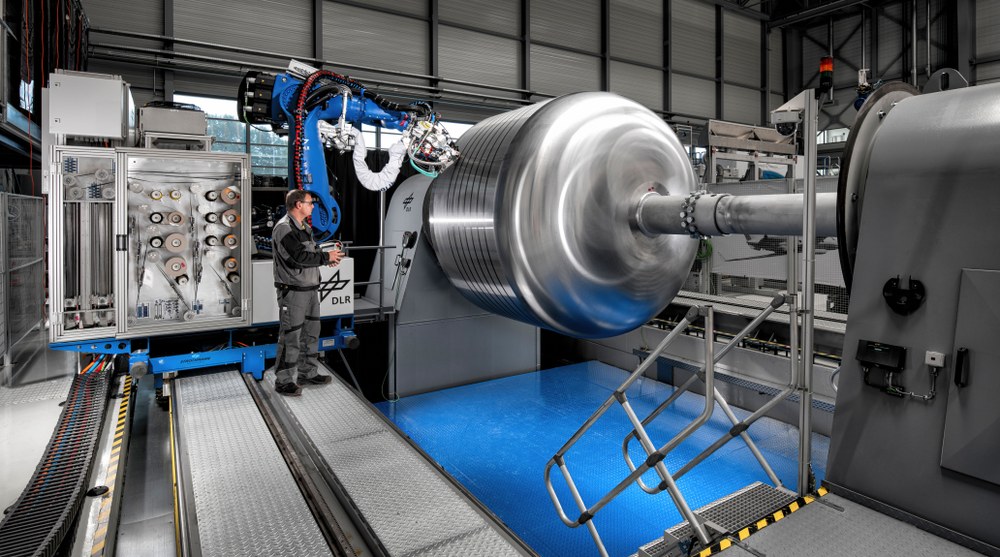

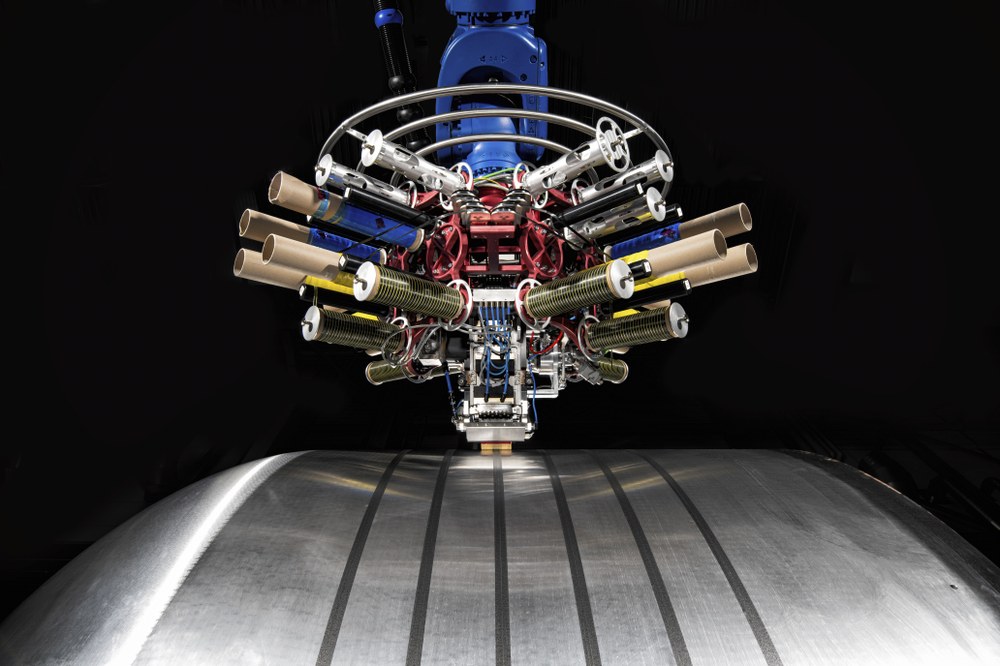

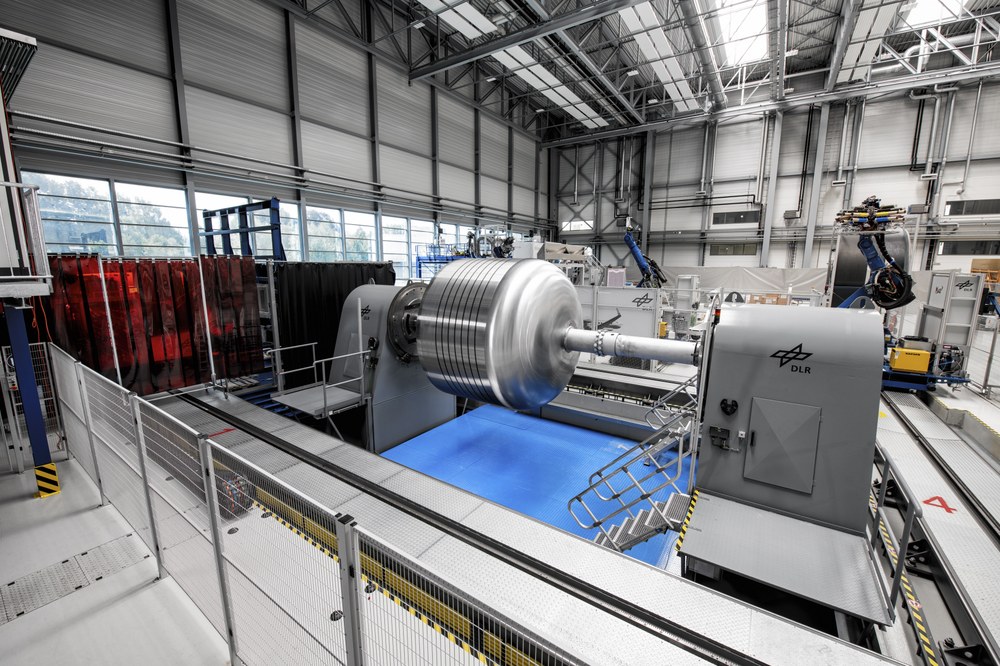

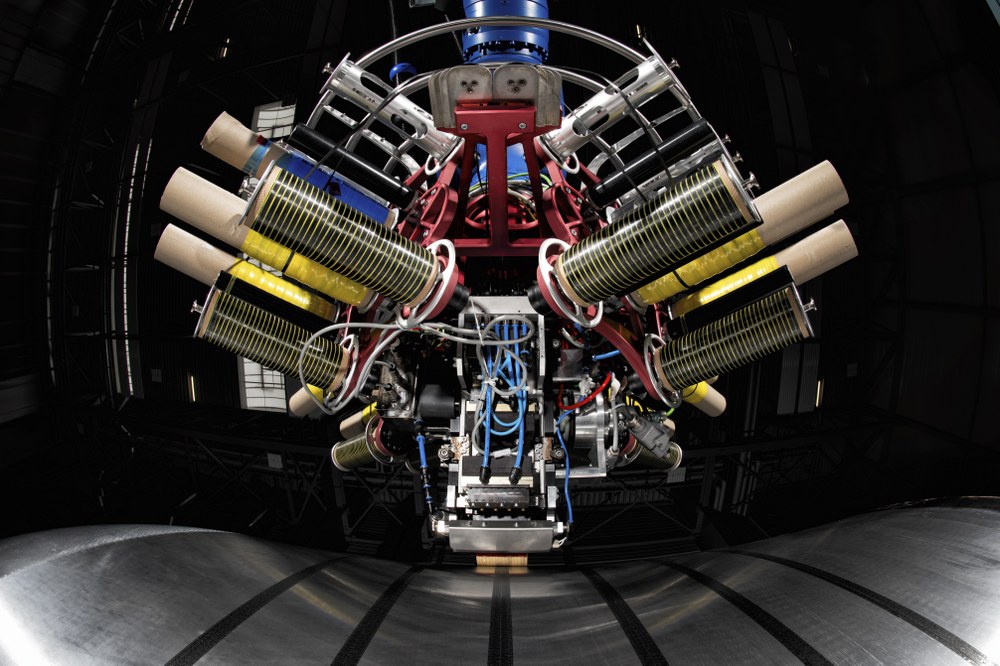

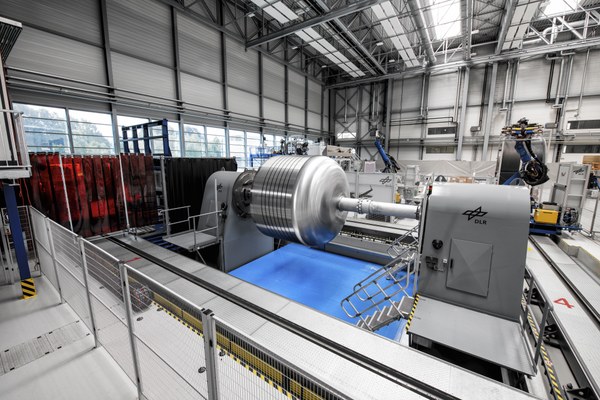

The AFP-world rotates

The use of hydrogen as a renewable and therefore sustainable energy source for future CO2-free drives holds great potential for decarbonisation. In addition to being used for heavy commercial vehicles or shipping, hydrogen is also used in aviation as an alternative energy source to paraffin or SAF (sustainable aviation fuels) to reduce CO2 emissions.