GREEN - Producing large components in a resource- and energy-efficient way

Sustainability as a design parameter for production machines and processes is becoming an increasingly important driver of innovation and thus an important competitive factor. In the GREEN project, significant improvements in resource efficiency can be realised through the data-based, integrated consideration of product, production machinery and process and demonstrated through representative use cases of large aircraft structure production.

While the VerticalE2E project focuses on optimising the strategically important production steps for aircraft parts, GREEN develops solutions to reduce the energy consumption of special machines and to reduce the use of resources by optimally coordinating the production steps in production lines. In other words, starting from production steps that are improved in themselves (VerticalE2E), the interaction is optimised from a process perspective.

Finally, with its horizontal integration approach, the planned project will make an important contribution to sustainable production in Lower Saxony and, together with the "VerticalE2E" joint project in Varel, will provide a holistic approach to improving sustainability in aircraft parts production. The GREEN project has the following overarching objectives:

- The overarching goal is the integrated design of production for productivity and sustainability. This requires a paradigm shift in which the optimisation of processes can only succeed through the integrated consideration of all relevant aspects.

- A holistic approach is being developed that understands the resource-saving product end-to-end in the context of economical systems and infrastructures as well as resource-optimised process control, thus opening up new optimisation potential.

- Representative use cases from production provide the boundary conditions in such a way that not only theoretical approaches but also realisable technologies for sustainable change are developed

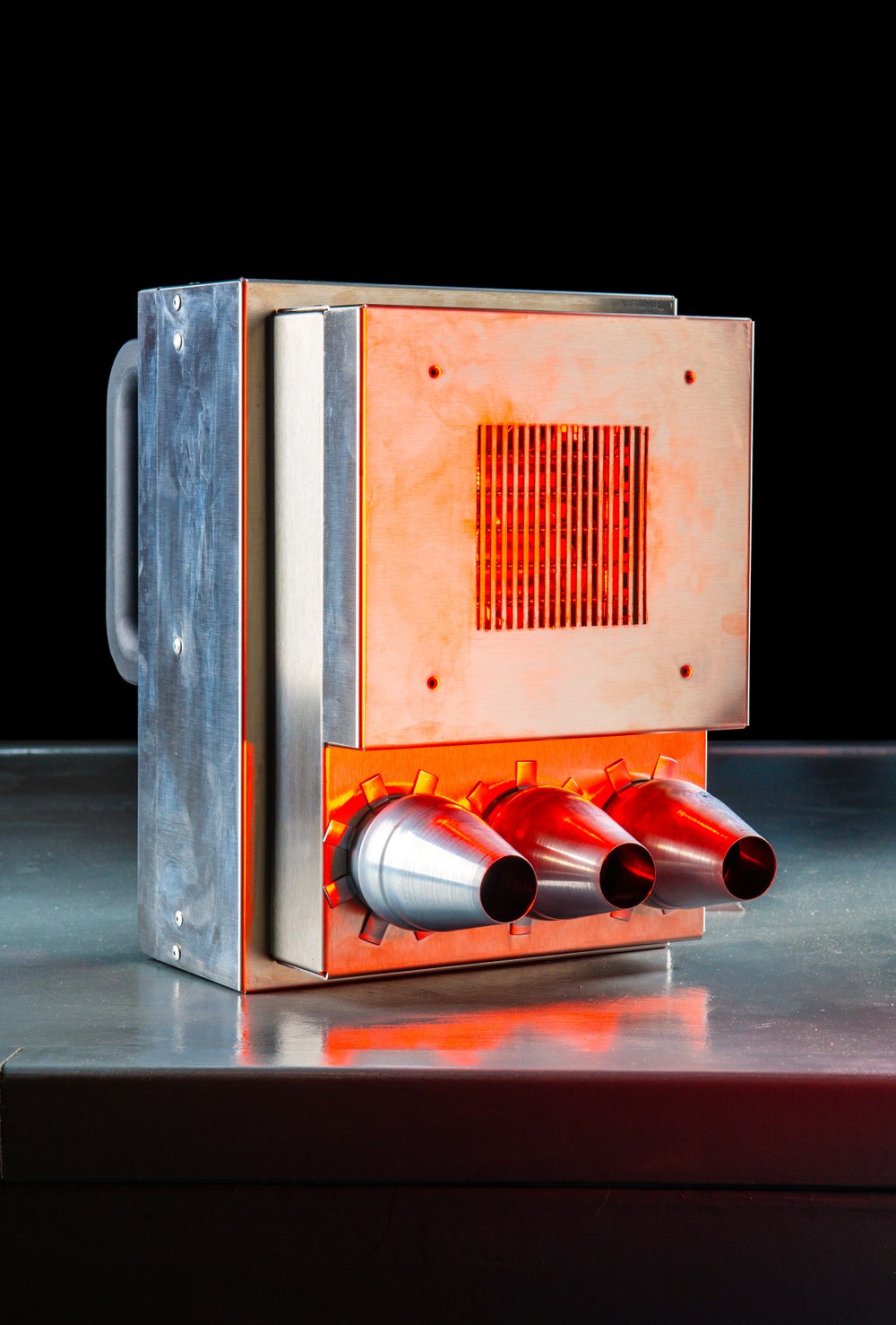

- DLR objective: Design and development of a resource-saving bonding process technology based on self-heated moulding tools.

The GREEN project brings together specialised expertise from the state of Lower Saxony to work together on the challenge of resource-saving production.

Project partners involved

Funding