Airfox

Airfox is a fuel cell system sizing and simulation tool for aviation applications, which is continuously developed by the Energy Storage Integration department. At its core, the tool is based on experimental data obtained from stack tests carried out in the laboratories of the group. This is supplemented by balance-of-plant models of varying levels of detail. A suitable overall system design is then determined by simulating each component in each point of a mission profile.

Modeling

Airfox includes subsystem and component models of varying levels of detail, validated with experimental data from real-world, commercially available components. This data is generated in-house at the test facilities of the department at ZAL in Hamburg. All models are steady-state, as the main objective of Airfox is to design and simulate the complete energy system of fuel cell aircraft over the flight mission.

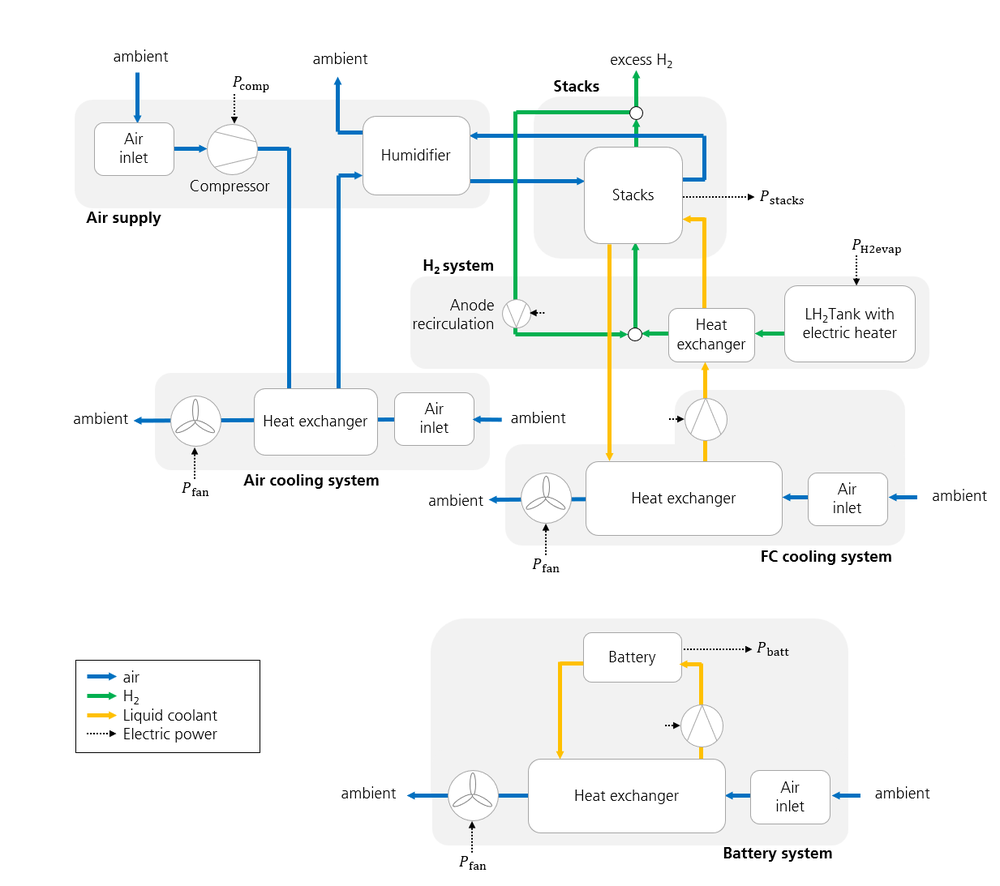

The energy system includes both the FC system (consisting of stack and balance of plant) and the battery system, as shown in Figure 2. The general approach for the overall system is modular, meaning that the different components can be combined in different ways to represent different system architectures, such as liquid or air cooling. While the tool is still under heavy development, the approach for stack modelling has already been published in a paper by Matthias Schröder, which can be found here. Airfox is written in Python.

Workflow

The typical Airfox workflow is divided into two parts:

1. the sizing and

2. simulation.

At the beginning, a mission profile is given as input, as well as a propulsion system concept that provides the relevant constraints to be considered.

The first step in the sizing step is to determine a system capable of satisfying a number of sizing points taken from the mission profile. This means that for each modelled component, resulting performance parameters such as efficiency are determined, along with values for its mass and dimensions. The various parasitic power requirements are then used to determine the total power required, leading to a final stack size.

In a second step, the entire mission is simulated using the resulting system. This means that for each subsystem the required power is determined, in particular the required stack current density. The results of this process can be presented in various forms, one of which is the graphical user interface shown in Figure 1, which is at a very early stage of development.

Application

The Airfox can also be used to analyse other heavy transport applications such as trains or ships. However, it is most commonly used for aircraft. It is used in many different projects across the Energy System Integration research groups. Typically, an aircraft is given in terms of its mission and required performance and design parameters, which impose constraints on the energy system. For example, this could be a 70-seat regional aircraft with propulsion distributed over 10 pods, each containing an FC system (see the Exact project). Once a feasible design has been obtained for these inputs, sensitivity studies can be carried out. For example, this could be a variation of the cathode inlet pressure. As this is increased, the compressor becomes heavier while the stack becomes more efficient and therefore lighter. The optimum point for this parameter can be found using the Airfox. Often the energy system sizing process is also included in an overall aircraft design loop, allowing the effects to be quantified at the overall aircraft level. The results of such studies are used in research projects, some of them with industrial partners, as well as in scientific publications. In this way, Airfox is being used to improve understanding of the challenges associated with the use of fuel cells in aircraft, thereby contributing to the integration of this technology into the next generations of truly sustainable aircraft.