QM-GDL

The GDL has a significant influence on the operating behavior and especially the performance of a fuel cell stack. In order to ensure high, consistent quality, reliable and comparable methods for characterizing and quality description of GDL materials should be developed. For this purpose, quality characteristics of a GDL and critical parameters are defined. In addition to examining factors influencing subsequent operation, methods should then be determined to be able to determine these characteristics randomly and continuously during the ongoing production process. This supports the entire supply chain for the market ramp-up of fuel cells.

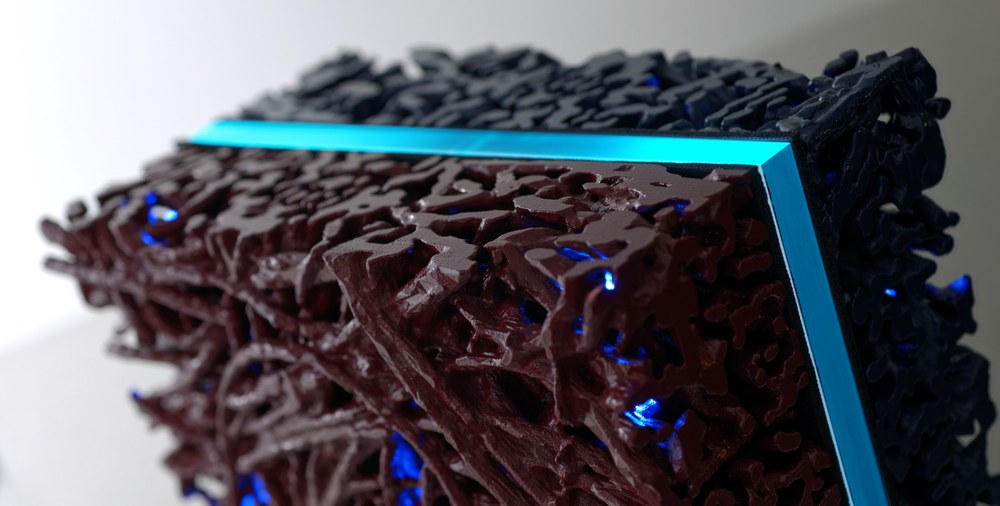

Gas diffusion layer as a central component of the fuel cell

The gas diffusion layer, or GDL for short, is a central component of the fuel cell. It has a variety of functions and tasks, which in addition to the mechanical ones also include the transport of reactants in the gas and liquid phases and the conduction of electrons and heat. The aim of the QM-GDL project is the joint development of standardizable test procedures for GDLs. In addition, the influence of material fluctuations on the operating behavior of fuel cells will be investigated. Overall, the project is intended to enable the development and mass production of more powerful GDLs.

Merge of a unique consortium

The technical know-how of the research institutions and industrial partners involved complement each other perfectly in order to solve this demanding task. Project participants include the DLR Institute of Technical Thermodynamics, the Forschungszentrum Jülich GmbH, the Fraunhofer Institute for Solar Energy Systems ISE, the Fraunhofer Institute for Chemical Technology ICT, the Center for Fuel Cell Technology GmbH and the Center for Solar Energy and Hydrogen Research Baden -Württemberg. Industry partners are SGL Carbon GmbH and Freudenberg Performance Materials SE & Co. KG

Project targets

- Definition of GDL quality characteristics and critical parameters

- Determination of methods for quality determination (ex-situ and inline)

- Examination of the influencing factors and transfer to operational use

- Definition of the requirements for GDL materials for later operation

- Creation of specifications and development of a requirement specification to determine quality parameters of a GDL

- Determination of the GDL parameters for inline quality determination during the ongoing manufacturing process and the ex-situ examination (random and continuous)

The work in the QM-GDL project provides quality specifications for the standardization of GDLs in the national area and thus gives the German supplier industry a competitive advantage in an international comparison and strengthens national hydrogen and fuel cell technology in the transport sector and in the energy market.

QM-GDL at a glance

Project | QM-GDL |

|---|---|

Duration | 1.3.2021 - 31.8.2024 |

Project Participants | Zentrum für Brennstoffzellen-Technik GmbH Zentrum für Sonnenenergie- und Wasserstoff-Forschung Baden-Württemberg (ZSW) Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung |

Financial Support |