FURTHER-FC

Fuel cells, as a highly efficient energy conversion technology, and hydrogen, as a clean energy carrier, have a great potential to reduce both carbon dioxide emissions and dependence on mainly imported hydrocarbons. The Polymer Electrolyte Membrane Fuel Cell (PEMFC) is the most promising technology for automotive applications with a large deployment horizon by 2030. However, in view of extending their use to a broad range of customers, progress have to be done in terms of cost, performance and durability.

The Fuel Cell Systems analysis for automotive applications presented by Strategic Analysis Inc. clearly shows the strategic importance to increase power density while simultaneously decreasing all component costs, and especially via the reduction of platinum loading. It is clear that filling the gap between State-of-the-Art and 2030 targets, will not be possible by incremental, or trial and error approaches. It is unanimously admitted that R&D efforts have to be focused on the MEA. Indeed, the MEA is at the heart of the PEMFC stack and is the most expensive component, representing about 60% of the stack cost.

FURTHER-FC objectives:

The FURTHER-FC project addresses the gap in understanding performance limitations due to the coupling between electrochemical and transport issues in the Cathode Catalyst Layer (CCL). Thereby, it aims at developing a unique, global, comprehensive and highly innovative route towards an improved understanding of performance limitations inside PEMFC. The focus is on the cathode catalyst layer (CCL) as the major bottleneck for performance, cost and durability issues for future high performing low-Pt loaded PEMFC.

The approach is combining all required original and/or most advanced experimental and modelling methods, with intensive fundamental characterizations coupled with advanced models on CCL of various compositions/structures integrating novel and pioneering materials in order to conclude on transport and electrochemical issues at the different scales of the CCL.

Thanks to this approach, FURTHER-FC proposed and validated new electrode structures specifically designed to prevent the limitations observed on SoA MEA and allowing to improve catalyst efficiency as well as power density. The approach also addresses the durability issues thanks to better understanding of the correlation between CCL microstructure, local conditions and properties.

The main objectives of the project can be summarized as follows:

- Describe the CCL structure and transport properties and mechanisms at its different scales

- Characterize the local conditions in the CCL during operation

- Establish the link between structure / properties of CCL, local conditions during operation, and performance

- Propose and validate structure and composition of CCL with improved catalyst efficiency and durability

Further-FC ambition:

The CCL is the most limiting component in terms of performance and durability, mainly due to the conditions in which the oxygen reduction occurs along with its sluggish kinetic. This is also the least understood component compared to gas diffusion layer or membrane. The fundamental reasons of performance limitations of CCL are still currently under discussion.

FURTHER-FC provides improved understanding of the relationships between the composition and the structure of CCL based on platinum/carbon nanoparticles, their effective transport properties and limitations and finally the overall fuel cell performance. This is a prerequisite to a rational design of effective CCL which will allow to make highly efficient and durable MEA with low platinum loading. Thus, FURTHER-FC improved the knowledge regarding:

- microstructure of the CCL

- correlation between transport properties and used components (catalyst, carbon, ionomer)

- local conditions in CCL during operation

- performance limitations induced by transport phenomena

- modelling of transport phenomena in CCL

The DLR's role in the FURTHER-FC project:

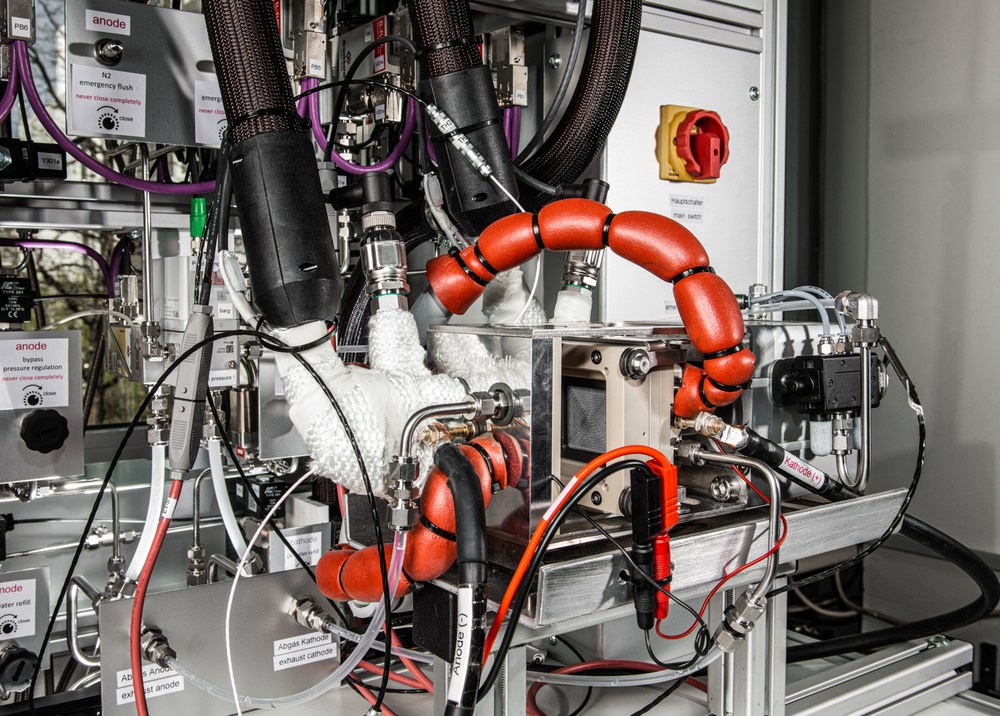

The goal of DLR was to improve the understanding performance limitations in CCLs at low Pt loading and low CCL thickness by the combination of modeling and experimental techniques. Thereby, mitigation approaches for performance limitations were developed and proposed. This includes:

- Study of CL parameters impact on CCL performance and transport properties using differential cells.

- Lattice Boltzmann simulations on agglomerate scale to investigate oxygen transport limitations.

- Multi-scale modeling of the single cell to link lower scale mechanisms with cell performance.

- Determination of O2 transport resistances

- Determination of proton transport resistances

- Establish a link between transport limitations and durability in the CL

Outcomes of FURTHER-FC:

A full parameter study using CCLs with different materials and compositions was used to identify electro-kinetic and mass transport limitations. The work was realized by detailed electrochemical measurements on customized MEAs combined with simulation of the involved processes. The cathode sides of these studied MEAs were modified to improve the understanding of the correlation between material properties and appearing limitations. For this purpose, the modifications included the variation of the cathode platinum loading, the ionomer-to-carbon ratio, the catalyst support, the platinum-to-carbon ratio, and the ionomer.

Within FURTHER-FC, the consortium could improve analytical and simulation tools:

- Improvement of electron tomography 3D imaging.

- Quantification of ionomer distribution.

- Determination of H+ and O2 transport properties in ionomer thin films as a function of temperature and relative humidity.

- Information on local water content as a function of relative humidity.

- Measurement of the effective CCL properties at the local and at the macroscopic scale.

- Development of in-situ and operando Raman thermography to determine membrane temperature.

- Upscaling approach to model effective transport property tensors based on 3D images.

- Link the material properties of ionomer and carbon with the cell performance by developing a scale bridging approach from the sub-µm scales to the cell scale.

- Implementation of an in-depth model validation which uses transient polarization curves, impedance spectra as well as limiting current analysis to assure the accurate representation of the different physical processes in the model.

The combination of these newly-developed and already existing tools enabled progress in various areas:

- Better understanding of the performance limiting processes (especially O2 transport in CCL) and proposal of different scenarios and hypothesis to explain these (some fully validated, others need to be studied in more detail).

- Better understanding of the influence of ionomer (D2020, HOPI), carbon support (graphitized, High Surface Area), and catalyst loading, for different operating conditions.

- Improved CCL with increased performance has been manufactured and demonstrated.

- Evidence of increased durability of MEAs using HOPI as ionomer in CCL for automotive application.

- Increased performance using HOPI ionomer also under heavy-duty relevant test conditions.

Consortium and funding:

FURTHER-FC relies on the unique complementarity, active involvement and strict cooperation of strong and renowned actors on manufacturing, experimental and modelling aspects. They bring partially exclusive expertise on unique and unavoidable experimental techniques and modelling tools from CCL component to cell level.

The two involved industrial partners Chemours and Toyota Motor Europe have provided new materials and knowledge about CCL manufacturing. Additionally, 8 academic partners were focused on the development of new analytic tools and on improved understanding of performance limiting mechanisms by the combination of these tools. This includes operando µ-Raman spectroscopy, operando SAS and electron microscopy, neutron Imaging, PGA, floating electrode and ultrathin CCL measurements, AFM and two-phase modelling in porous media.

This project has received funding from the Fuel Cells and Hydrogen 2 Joint Undertaking (now Clean Hydrogen Partnership) under Grant Agreement No 875025. This Joint Undertaking receives support from the European Union’s Horizon 2020 Research and Innovation program, Hydrogen Europe and Hydrogen Europe Research.