PEMTASTIC

The PEMTASTIC research and development project aims to increase the durability of membrane electrode assemblies (MEA) for heavy-duty applications. This challenge will be addressed with a combination of model-based design of a long-life CCM using innovative materials tailored for high-power operation at high temperatures (105°C).

The quantitative targets correspond to a lifetime of 20,000 hours and a power density of 1.2 W/cm2@0.65 V at a Pt load of 0.30 g/kW. The following activities will be carried out to achieve this goal:

- Analysis of relevant truck driving profiles [->Symbio] to derive fuel cell operating protocols and stressors to be implemented on test rigs.

- Degradation tests in differential cells supported by physico-chemical material characterisation to ensure defined data for the parameterisation of degradation models [->CEA, DLR].

- Combination of micro- and mesoscale models as well as 1D and 2D cell models ->[ZHAW, DLR] to capture the influence of material parameters on performance and durability and to derive improvement recommendations for material and CCM parameters, which are iteratively adapted by the industrial partners.

- Implementation of new customised materials: advanced corrosion resistant support materials [->IMERYS] in combination with a novel catalyst deposition technique [->Heraeus] to mitigate the loss on the electrochemical surface area (ECSA). Prototypes of Nafion ionomers and membranes with high conductivity under dry conditions are used [->Chemours]. Finally, an improved cathode catalyst layer is developed taking into account the Pt particle size distribution and an optimised catalyst-ionomer interaction [->IRD]. A wide range of operating conditions is taken into account when selecting a commercially available gas diffusion layer (GDL).

- Validation of the final MEA and the concept of model-based MEA development in a short fuel cell stack at Technical Maturity Level 4 (TRL4) [->Symbio].

- The effects on system management and system components are considered as additional results. In addition, the reduced computational effort for degradation modelling will enable rapid condition detection and prediction.

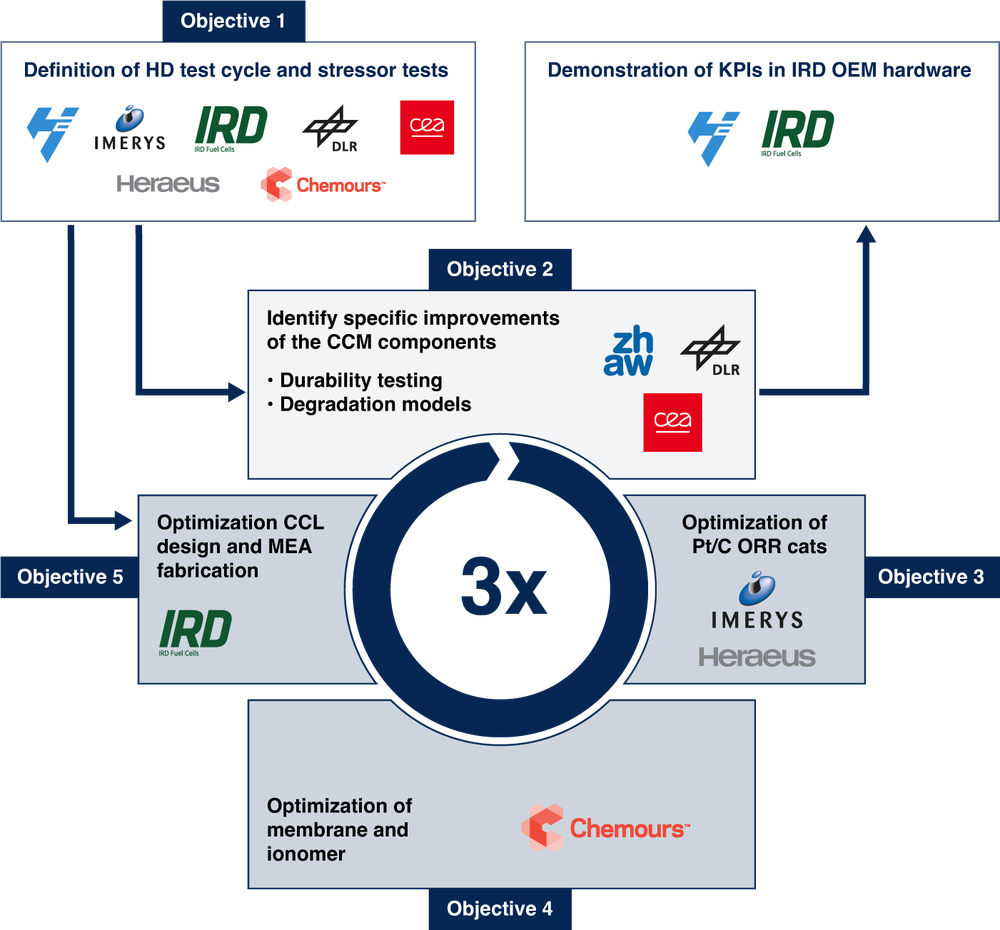

Objectives

To overcome durability hurdle of polymer electrolyte membrane fuel cells (PEMFC) and in line with the Strategic Research and Innovation Agenda (SRIA) of the Clean Hydrogen Joint Undertaking, new application-tailored component materials, cell designs and operating strategies must be developed.

This is the purpose of the PEMSTATIC project which aims at bringing to technology readiness level (TRL) 4 the highly innovative concept of durable heavy duty membrane electrode assembly (MEA) derived from enhanced degradation models and addressing the different sub-components of the catalyst coated membrane (CCM) and their interactions.

Objective 1: Define fuel cell operation protocols and cycling tests for heavy duty application and propose operation strategy for high fuel efficiency

Objective 2: Parameterisation of degradation models to predict MEA lifetime and identify specific improvements of the CCM and its components

Objective 3: Development of robust catalyst support and deposition process for catalysts

Objective 4: Development of membrane and ionomer for operation at increased temperature

Objective 5: Catalyst layers and CCM with increased durability and state-of-the art performance tailored for heavy duty operation

Objective 6: Ensure the dissemination of the project results and the promotion of the project, through ad-hoc strategies through target groups and key stakeholders and define the exploitation strategy of the PEMTASTIC outcome

Tasks at DLR for this project

The institute is the project coordinator of this project and is responsible for other tasks such as MEA characterisation and degradation modelling.

PEMTASTIC Video

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

PEMTASTIC at a glance

Full project title |

ROBUST PEMFC MEA DERIVED FROM MODEL-BASED UNDERSTANDING OF DURABILITY LIMITATIONS FOR HEAVY DUTY APPLICATIONS

|

|---|---|

Duration |

|

CleanH2 financial support | 2.998.000 € |

Further financial support | 937.000 € |