KelnEr

As the electrification of industrial processes continues apace, there is an increasing demand for technologies that can reach process temperatures of well above 1000 °C, providing an alternative to today's fossil natural gas burners.

In addition to high operating temperatures, compactness, costs and performance requirements must also be met in order to accelerate the "heat transition" in numerous industrial sectors with this retrofit option. Adapted induction heating solutions open up a high level of economic competitiveness and rivalry with natural gas or hydrogen burners thanks to their high efficiency in the conversion of electricity to heat, scalability, power density and, in particular, the availability of industrial induction technology.

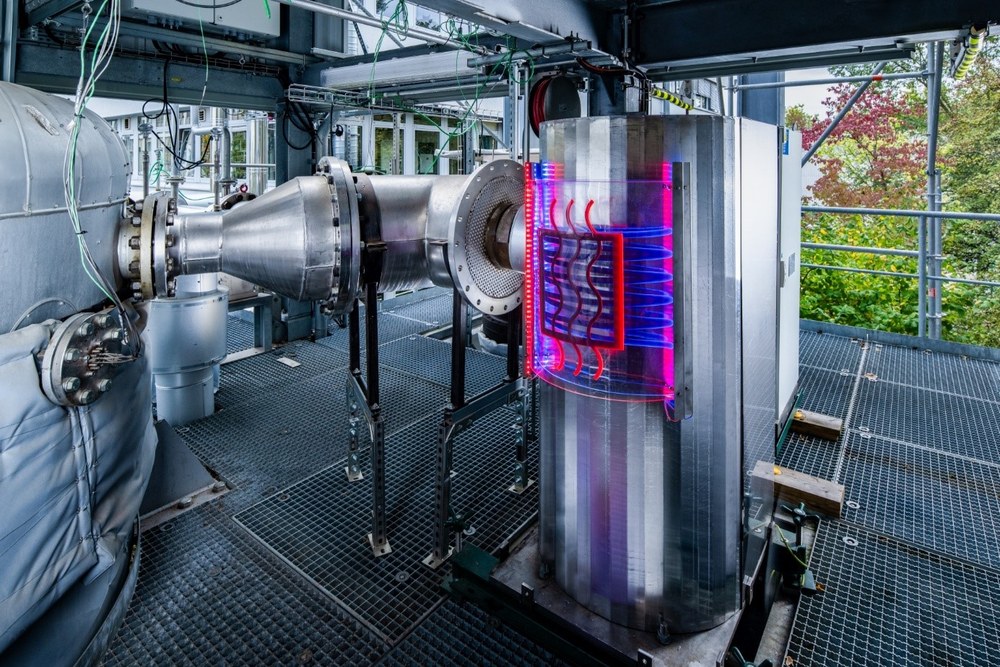

Initial research and development work, based on electrically conductive, inductively heatable high-performance ceramics has already been successfully carried out at a laboratory and pilot plant scale, confirming the feasibility and potential of the new technology. The further development and demonstration of the inductive ceramic heating component into a technically valid, durable and economically competitive prototype solution is the focus of the KeInEr project. The main challenges are to realise an energy-efficient, compact and at the same time cost-effective heater solution with a high efficiency of more than 90% and a high power density of more than 2 MW/m3 under application-specific boundary conditions.

Central research and development tasks

• Development of a holistically coordinated and cost-optimised design with high conversion efficiency, power density and lifetime

• Experimental validation of the prototype under application-specific operating conditions

• Proven oxidation protection to increase lifetime of high-performance ceramics

• Identification of the cost-efficient production route for high-performance ceramics

KelnEr at a glance

KelnEr |

Ceramic induction air heater |

|---|---|

Duration | 01. January 2024 - 30. June 2026 |

Participating institutes |