BALIS

In the BALIS project, DLR is developing the world's first fuel cell drive train for aircraft - with an output in the megawatt range. DLR is thus taking a further step towards enabling emission-free flying with hydrogen.

Reducing greenhouse gas emissions in aviation is a challenging and largely unsolved task. A change in propulsion based on fuel cells, which convert the reaction energy of hydrogen and oxygen into electrical energy while only emitting water, is a promising way to avoid greenhouse gas emissions. However, so far there is only one fuel cell-powered passenger aircraft with an engine power of 80 Kilowatts and four seats. Enabling regional aircraft with 40 to 60 seats and a range of 1,000 kilometers requires significant upscaling of existing components.

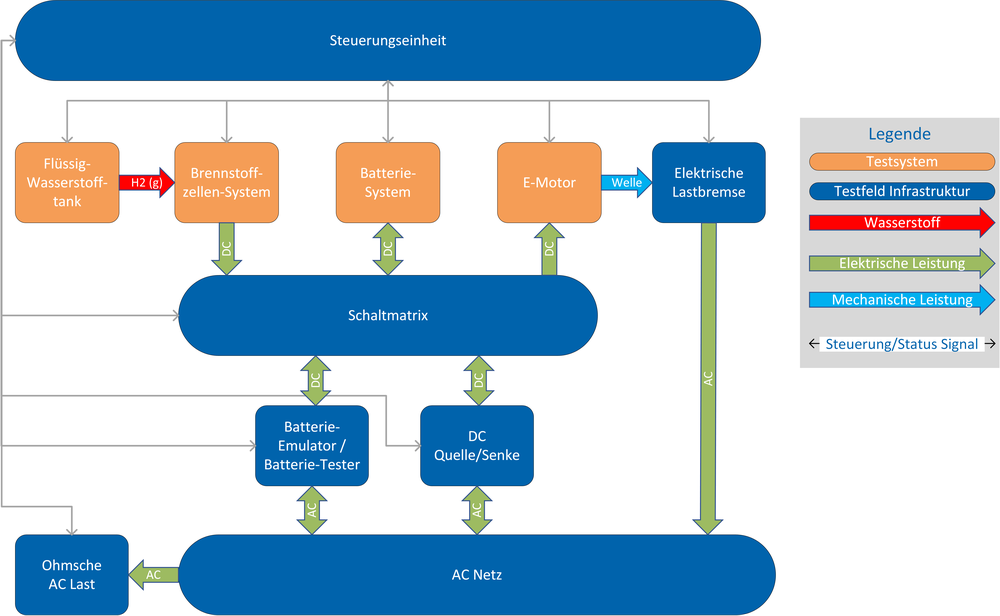

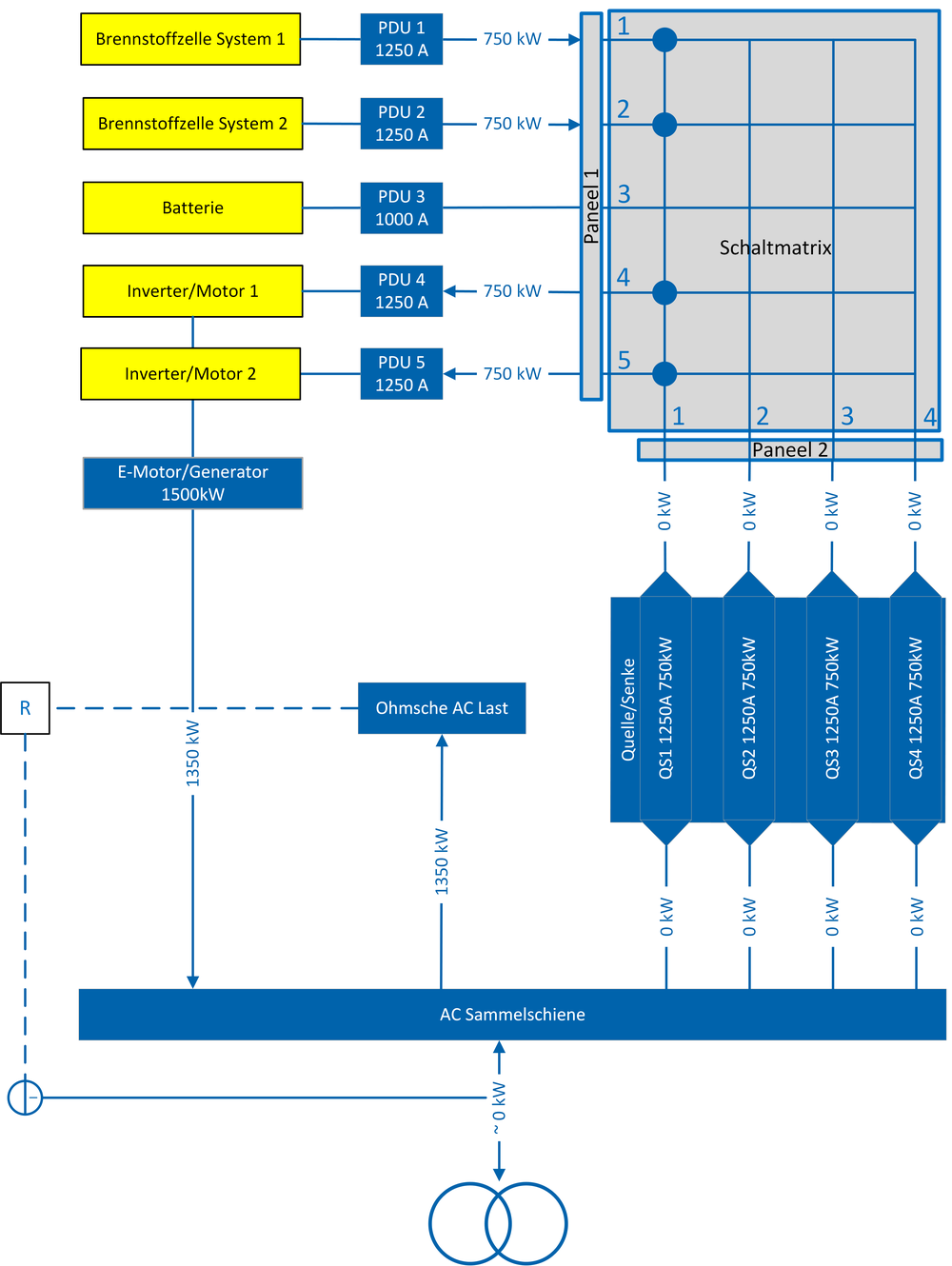

To demonstrate upscaling to 1.5 Megawatts, DLR is building a unique test environment with several industrial partners as part of the BALIS project (fuel cell-based powertrain for aircraft 1.5+ Megawatts), which includes the core components consisting of a fuel cell system, a tank for liquid hydrogen Drive unit and a battery as well as the control and regulation technology including the associated infrastructure (see Figure 1). The components can be operated and tested both individually and in combination using a switching matrix. This makes it possible to simulate and examine any load case for an aircraft for each component and the entire system.

An example load profile is shown in Figure 2. Here, the movement to the runway is first simulated at a low speed. During the subsequent startup phase, maximum system performance is used for 10 minutes. The aircraft then climbs to the desired cruising altitude within 20 minutes with a high power of 1.2 Megawatts, which is then maintained at medium power for 60 minutes.

The test environment, funded by the Federal Ministry of Transport and Digital Infrastructure (BMVI) with 26 million euros, will be set up in several module containers on the Innovations Campus Empfingen near Stuttgart. Coordinated by DLR, an industrial system partner is setting up the necessary measurement and testing infrastructure. The flight-relevant core components are developed in collaboration with several technology partners and integrated into the test environment. Construction is scheduled to begin in October 2021 and the demonstration of the entire system will take place by the end of the project in June 2023.

The BALIS test environment makes it possible to test the core components of a drive train based on fuel cells and/or batteries as well as their effect on the entire drive system realistically and easily. The test environment can therefore contribute to faster development of components and thus accelerate the market readiness of fuel cell or battery-based aviation systems.

BALIS at a glance

Project | BALIS2 |

|---|---|

Duration | January 2021 until July 2023 |

Project participants | |

Financial support | Federal Ministry for Digital and Transport (BMDV) National Innovation Programme Hydrogen and Fuel Cell Technology (NIP) NOW (National Organization for Hydrogen and Fuel Cell Technology) |