Thermal Systems for Liquids

The Thermal Systems for Liquids speciality is dedicated to the development of molten salt storage tanks. Our research focusses on new materials for a wider temperature range and innovative storage systems that reduce both operating costs and capital expenditure. The approaches are investigated in the technical centre and with the test facility for heat storage in molten salt (TESIS) up to the megawatt scale. We are also evaluating the techno-economic integration of these technologies in real applications.

Fields of application

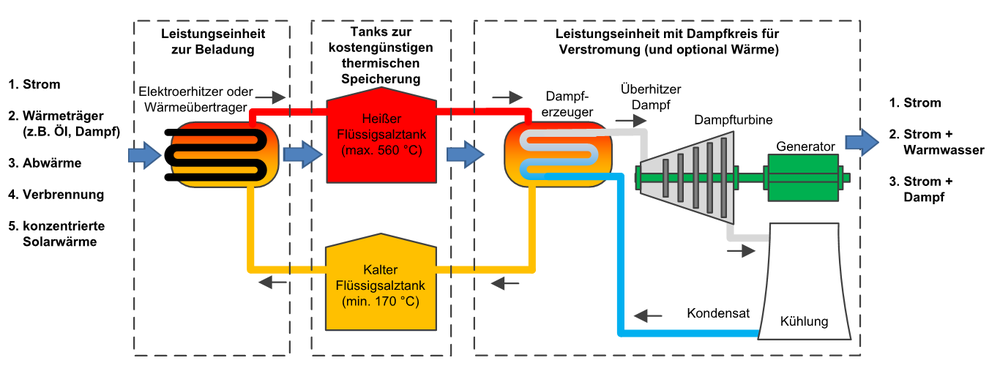

The molten salt systems developed by our research department are already being used commercially in solar thermal plants on a GWh scale. The focus is on the transfer to industrial processes and large-scale electricity storage systems at temperatures of 170 °C to 700 °C.

Expertise

In order to increase operating temperatures (up to 700 °C) and optimise material compatibility, we are developing new material systems with a liquid charge. We investigate methods for the purification and stabilisation of chloride and nitrate salt systems. In our laboratories, we quantify the interactions between liquid salts and the gas phase as well as material compatibility and metallic corrosion. This opens up new fields of application for liquid salts.

With operational experience since 2018 in the construction and operation of the 4 MWh single-tank molten salt storage tank (TESIS:Store) and the component test track (Tesis:com) for testing molten salt components (valves, electric heaters, etc.), we are ideally equipped to expand the possible uses in various industrial applications.

The simulation and process integration of our molten salt systems is aimed at establishing them in conventional power plants (Third Life for coal-fired power plants) and electricity storage systems (Carnot batteries), as well as in the field of industrial process heat. The focus of the research work is on techno-economic optimisation.

In summary, our expertise ranges from new materials with a wider temperature range, to new storage systems with lower operating and investment costs, to system integration in large-scale plants.