Solid oxide electrolysis and fuel cell systems

This research area develops process engineering systems with electrochemical high-temperature reactors that operate at 600-850°C. The focus is on solid oxide cells (SOC). The focus is on solid oxide cells (SOC), which are used both in electrolysis mode (SOEC) for the production of hydrogen and synthesis gases and in fuel cell mode (SOFC) for emission-free energy generation. These reactors offer the highest levels of efficiency and can even contribute to the direct electrochemical synthesis of fuels and chemicals in the long term - a decisive step towards a sustainable energy future.

Fields of application

The division focuses on the development of multifunctional fuel cell systems and innovative electrolysis technologies that are specially tailored to the requirements of demanding applications such as marine propulsion or industrial energy systems. The focus is on the selection of suitable components, systematic modelling and simulation as well as customised system designs. The aim is to develop critical system components, improve system integration, optimise operating strategies and develop concepts for upscaling.

Targets are:

- Efficient operating strategies: Development of strategies for efficient, long-lasting and low-degradation operation of integrated electrolysis and fuel cell systems.

- Scaling of energy systems: Research and development of electrolysis systems in the 100 MW+ range and fuel cell systems from 10 MW+.

- System integration and simulation: Experimental and simulative analyses of coupled fuel cell systems and upstream/downstream processes in the 100 kW+ range.

- Hybrid systems of the future: Development of highly efficient hybrid systems with minimal need for power electronics and optimised direct coupling of battery and fuel cell systems.

Expertise

The close intermeshing of simulation and experiment is of key importance for the work of the research area. A combined approach that closely links four scientific methods and instruments is used to achieve the objectives.

Developing and analysing system concepts (Simulationtool: CELESTE)

Thermodynamic and reaction kinetic simulation for energy and exergy analysis; development and comparison of process engineering system configurations, focussing on the integration of electrochemical reactors.

Transient, process engineering system simulation (Simulationtool: TEMPEST)

Process simulation focussing on electrochemical reactors to develop and research operating strategies for overall and sub-processes in process engineering.

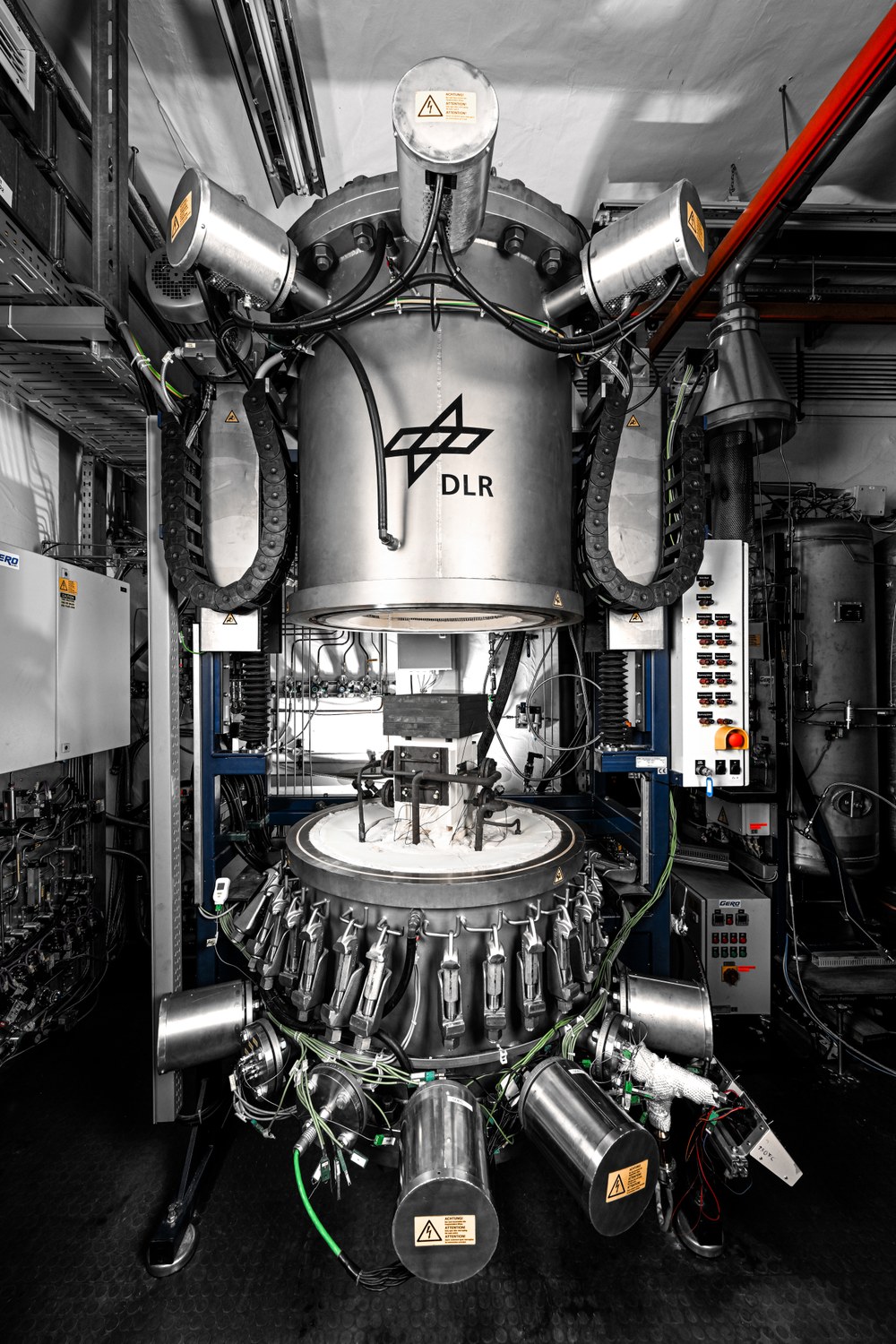

Experimental reactor investigations

Pressurised and atmospheric tests on SOC stacks (up to approx. 2 kW on test stand) HORST Pressurised and atmospheric tests on SOC stacks (up to approx. 2 kW on test stand) GALACTICA); Parameterisation and validation of the CELESTE and TEMPEST models; testing of operating strategies from TEMPEST simulations.

Process engineering system experiments

Construction and operation of exemplary, complex process engineering process chains/sub-process chains (e-XPlore: pressurised SOC electrolysis system for direct coupling to downstream synthesis processes; hybrid power plant: virtually coupled hybrid power plant consisting of pressurised SOFC and gas turbine).