High Temperature-PEM-Fuel Cells

Renewable energy technologies are of great importance to society in order to reduce emissions of CO2 and other pollutants in Germany, Europe and worldwide. Hydrogen is used to effectively store energy chemically and utilise it electrically in fuel cells. Based on electrochemical processes, fuel cells are CO2 emission-free, quiet and can be more efficient than conventional combustion technologies. In order to implement sustainability and resource conservation holistically from the outset, long-term and corrosion stability, simplified production processes with standardised quality control, cost efficiency and environmental compatibility of components must be addressed.

Fields of application

High-temperature PEM technology is used alongside electrochemical hydrogen separation for fuel cells and has an operating temperature range of 120-200°C. Higher tolerances to carbon monoxide or sulphur-based contamination compared to PEM technologies enable operation with reformed hydrogen based on e.g. methanol in maritime applications and the perspective fuel flexibility in portable systems, for example.

By avoiding active cell humidification and improving cooling, the system design is also simplified. This is relevant for aviation applications in terms of the volume, mass and energy consumption of the fuel cell powertrain.

Expertise

At the DLR Institute of Technical Thermodynamics in Oldenburg, high-temperature PEM fuel cells are analysed and developed holistically in terms of power density, long-term and corrosion stability, standardised quality control, cost efficiency and environmental compatibility (PFAS-free). This includes individual components such as electrodes through to the membrane electrode assembly (MEA) and individual cells.

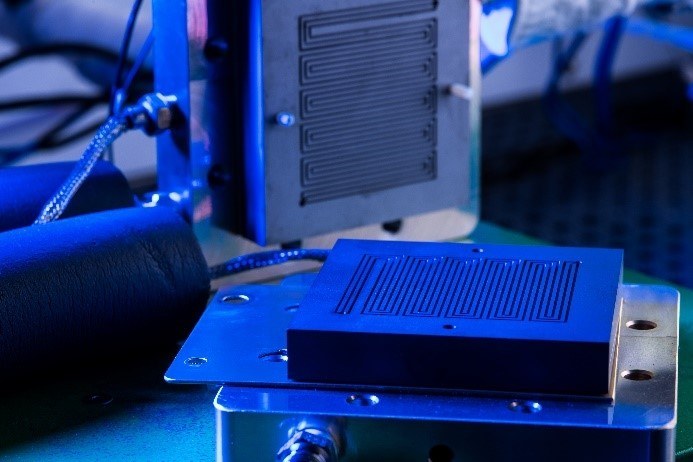

- Test stands for high-temperature/low-temperature PEM single cells up to 25 cm² (see Figures 1 and 2) under controlled conditions (application-related load profiles, contamination and degradation tests, stress and long-term tests of 1,000 h or longer).

- Computed tomography for the non-destructive 3D analysis of components and cells of various types with a resolution of up to 100 nm and possible combination with other 2D/3D analysis.

- Coating techniques for electrodes (doctor blades and ultrasonic spraying).

- Chemical/physical analysis like X-ray fluorescence analysis (XRF), high-resolution mass spectrometry with inductively coupled plasma (ICP-MS) with laser ablation and laser-induced plasma spectroscopy (LIBS), contact angle determination (Fig. 3), thermogravimetric analysis (TGA), ion chromatography (IC), Ramanspectroscopy (etc.).

In addition, cost-efficient catalysts and electrodes for various electrochemical processes (oxygen reduction reaction, CO2 reduction reaction, ...) are being developed across all applications:

- Wet-chemical synthesis of precious metal-free single-atom catalysts and thermal treatment using a high-temperature furnace up to 3,000 °C (Fig. 4).

- Catalyst screening by means of rotating ring disc electrode (RRDE) with regard to activities, selectivities and stabilities and possible coupling with IL-TEM (transmission electron microscopy with identical location before and after electrochemical investigations).

- Half-cell setups for analysing the performance and stability of gas diffusion electrodes (GDEs) with possible variation of temperature, electrolyte or active electrode surfaces.