Battery Technology

Batteries are considered a key component in the transition towards a climate-neutral society. Their integration into portable devices, such as notebooks and smartphones, has already become substantial part of our daily lives. At the same time, the continuous progress made in recent years is increasingly opening up new fields of application, including electromobility and the use of batteries to store fluctuating, renewable electricity from wind and solar power are becoming increasingly important. Consequently, batteries are already making an important contribution to reducing dependency on fossil fuels and diminishing climate-altering emissions in the energy and transport sectors.

Fields of application

Lithium-ion batteries have led to a breakthrough in electromobility due to their high energy density, long service life and constantly falling costs. While this itself still offers a great deal of development potential, next-generation batteries promise specific advantages in terms of cost, performance and sustainability.

Zinc-air or sodium-ion batteries, for example, could play an important role in stationary energy storage and in applications where costs are crucial due to their potentially lower costs and the absence of critical raw materials. The same applies to cell technologies based on readily available materials such as calcium, magnesium or sulfur. These innovative cell chemistries not only address the social requirements for sustainability aspects, but also the growing importance of material availability and stable supply chains.

Lithium-sulfur or solid-state batteries, on the other hand, are of great interest for aerospace applications that place particularly high demands on weight and reliability. These technologies not only offer increased energy density, but also the potential for improved safety features and are therefore the subject of intensive development efforts at the DLR.

Expertise

DLR covers the entire spectrum of battery research. This ranges from the investigation of elementary processes at the level of active materials and the development of new cell technologies to the integration of battery packs and methods for monitoring them for applications in transport, aviation and space systems.

The experimental work at material and cell level in Stuttgart forms the interface between basic research and the transfer of knowledge to the diverse applications of DLR research. The researchers are particularly focused on better understanding the complex processes within the battery cell and how these determine the performance, longevity and safety of the cell. With the knowledge gained and using various syntheses and manufacturing methods, components are being developed for new cell technologies that offer advantages in terms of cost, material availability or energy density. The combination of experiments and simulations provides in-depth insights into the interior of the cell and enables the components to be optimised according to the requirements of the application. The work can be roughly divided into three subject areas.

Method development

An overarching focus of the work is the investigation of cells, components and materials using innovative in situ, operando and electrochemical methods. This includes, among other things

- Special setups for analysing electrochemical, transport and degradation processes during operation (e.g. using operando X-ray diffraction, UV/Vis or Raman spectroscopy);

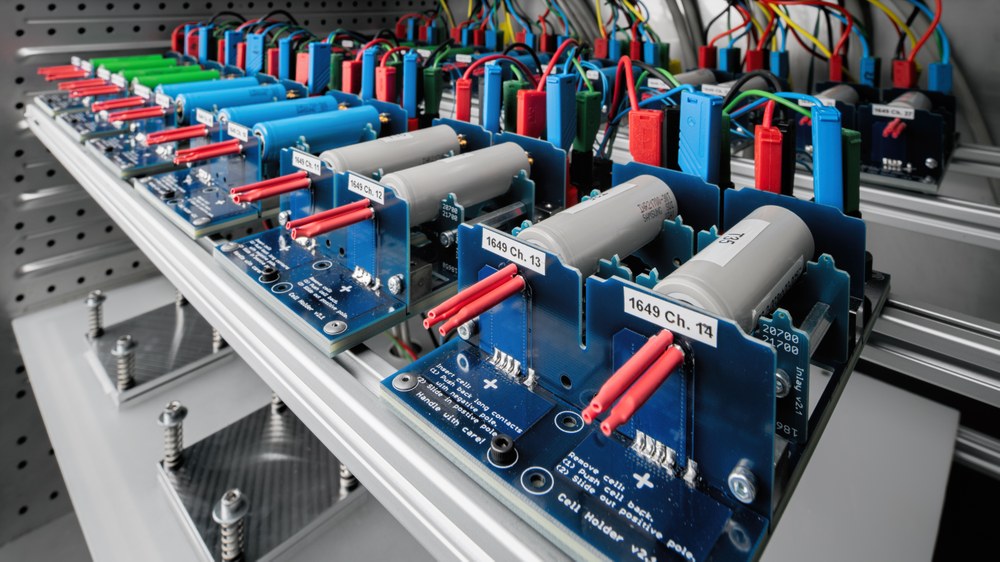

- >150 channels for characterising the cycling and degradation behaviour in laboratory, commercial or prototype cells (-40 °C to 60 °C) as well as post-mortem examinations after operation using advanced analytics such as scanning electron microscopy with focused ion beam (FIB-SEM), X-ray photoelectron spectroscopy (XPS), micro-computed tomography (µCT), etc.;

- State diagnostics of cells using electrochemical methods such as electrochemical impedance spectroscopy and sensors integrated into the cell;

- special methods for accurate and efficient parameterisation of simulation models.

Lithium-ion-batteries

Work in the field of lithium-ion batteries includes the comprehensive characterisation of commercial and prototype cells combined with post-mortem investigations at the end of life to identify ageing mechanisms. New cell components and active materials for use in aerospace and electromobility are also being investigated in various activities. The range of services includes

- ageing campaigns of commercial battery cells and degradation analysis using advanced electrochemical methods and post-mortem analysis;

- qualification of cells for various applications, development of operating strategies to ensure performance, safety and longevity;

- investigation of novel cell components and active material combinations from single particle to cell level.

Post Lithium-ion-batteries

In addition to lithium-ion batteries, special attention is paid to next-generation cell technologies (including metal anodes, metal-sulfhur, zinc-air and solid-state batteries), which promise advantages in terms of gravimetric and volumetric energy density as well as material availability and sustainability. These include metal anodes such as lithium, calcium or magnesium, metal-sulfur/metal-air batteries and solid-state batteries. In addition to operando characterisation and investigation of degradation phenomena (see above), the work primarily involves the development of nano- and microstructured electrodes and components for metal-sulfur and metal-air batteries in order to increase performance and cycle stability.

- Electrode development and model-based design of components for metal-sulfur and solid-state batteries.

- Fundamental investigations of electrochemical and transport processes, electrolyte properties and boundary layer phenomena.

- Development of electrocatalysts and gas diffusion electrodes for metal-air batteries and CO2 electrolysis using scalable manufacturing technology.