Fuel cell technology for climate-neutral shipping: zero4cruise project launched

MEYER WERFT

- Proton Exchange Membrane (PEM) fuel cells are being developed for maritime applications in the zero4cruise project.

- The aim is to activate the market for fuel cell technology for cruise ships.

- Funded by the German Federal Ministry of Economics and Technology with €18.7 million

- Focus: Energy, shipping, fuel cells

The shipping industry is facing a fundamental change: growing environmental awareness and increasing regulatory emission requirements call for innovative solutions to make passenger ships more climate-friendly. In the zero4cruise project, DLR, together with Meyer Werft and Freudenberg Fuel Cell e-Power Systems, is further developing PEM fuel cell technology for large-scale maritime systems. The project is funded by the German Federal Ministry of Economics and Technology with a total of 18.7 million euros.

New propulsion concepts for a sustainable future

The shipping industry is called upon to reduce climate-harmful emissions and introduce more environmentally friendly propulsion technologies. Conventional propulsion systems based on diesel engines are increasingly reaching their technical and economic limits.

The zero4cruise project aims to develop and promote more climate-friendly propulsion systems. The aim is to develop innovative energy and propulsion concepts that are suitable for both newly build ships and retrofits.

Focus on fuel cell technology

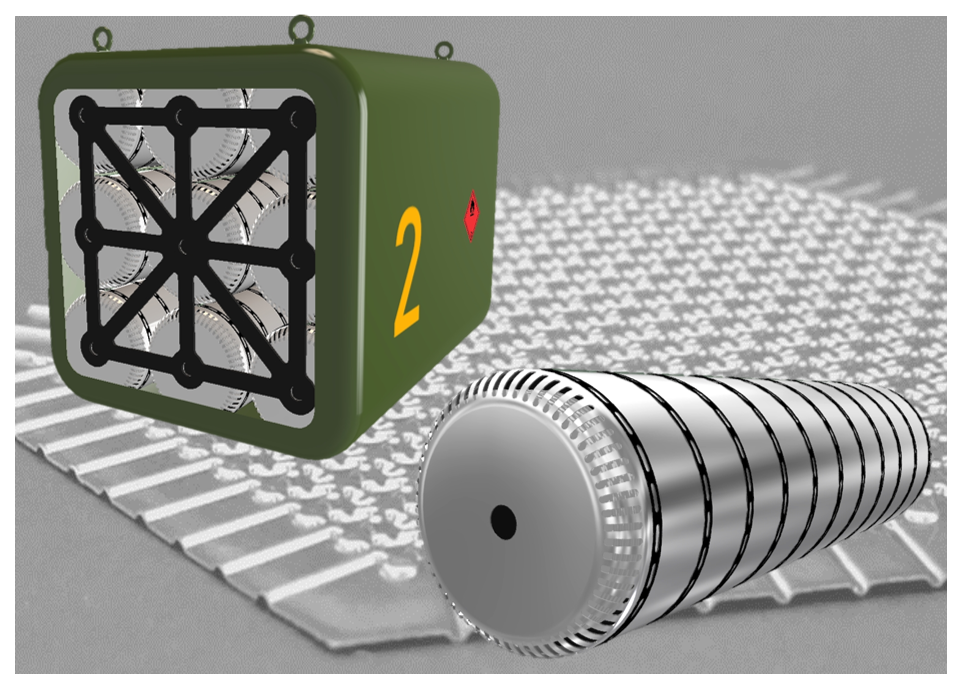

A key focus of the project is the further development of PEM (Proton Exchange Membrane) fuel cell systems for large-scale maritime applications.

Combined with methanol as an energy carrier, this technology offers great potential for supplying ships with electricity, heat and cooling - efficiently and with low emissions. Building on the developments and experience of involved partners, this technology will be further developed to achieve market maturity - the use of fuel cell systems on board opens up new opportunities for shipping to move towards climate neutrality.

The consortium behind zero4cruise

The project brings together the expertise of leading partners:

- MEYER WERFT, one of the world's leading shipyards,

- Freudenberg Fuel Cell e-Power Systems, which specialises in fuel cell technology, and

- German Aerospace Centre (DLR), which brings many years of research experience in the field of zero-emission propulsion. DLR's role in zero4cruise includes pre-development and testing of the technology for large maritime stacks and systems.

- The DLR Institute of Engineering Thermodynamics is responsible for the pre-development of fuel cell stacks on a scale relevant to the maritime market. This includes the consistent implementation of innovative technology approaches in the field of both LT-PEM and HT-PEM. The aim is to build prototype fuel cell stacks with 250 kW (LT-PEM) and 120 kW (HT-PEM), including performance verification in the laboratory.

- The DLR Institute of Maritime Energy Systems is carrying out long-term tests on a 500 kW maritime fuel cell system. The aim is to simulate the real load cycles of a cruise ship in order to prove the long-term suitability of the system.cIn addition, newly developed LT and HT PEM fuel cell stacks will be tested in the Maritime Energy Laboratory to ensure development to system level.

The project participants are pursuing the goal of driving forward the market activation of fuel cell technology for ocean-going passenger ships. This includes the development and scaling of large-scale systems that fulfil the specific requirements of the maritime sector - such as performance, reliability and service life.

BMWK.

PtJ.