Project launch for sustainable catalysts and gas diffusion electrodes in the chemical industry

The „DisCO2very“ project (materials for industrial CO2 utilisation: from electrocatalysts to sustainable electrodes) was launched on 1st July 2024 as part of the "MaterialNeutral - Resource Sovereignty through Material Innovation" materials hub initiative funded by the German Federal Ministry of Education and Research (BMBF). The DLR Institute of Engineering Thermodynamics is involved in the project and is developing catalysts and gas diffusion electrodes for CO2 electrolysis.

Utilization of CO2 exhaust gases

The chemical industry is a major contributor to Germany's greenhouse gas emissions, accounting for around 15 %, as it is both energy-intensive and highly dependent on fossil fuels. In order to achieve climate neutrality by 2045, key measures are required. This includes the substitution of fossil raw materials and the integration of renewable energies into production processes. One promising alternative is the use of CO₂ from waste gas streams from various industries, biorefineries and, in the long term, from the air. As a new raw material, this CO₂ could form the basis for the production of basic and fine chemicals.

Inexpensive and resource-saving gas diffusion electrodes for CO2 electrolysis

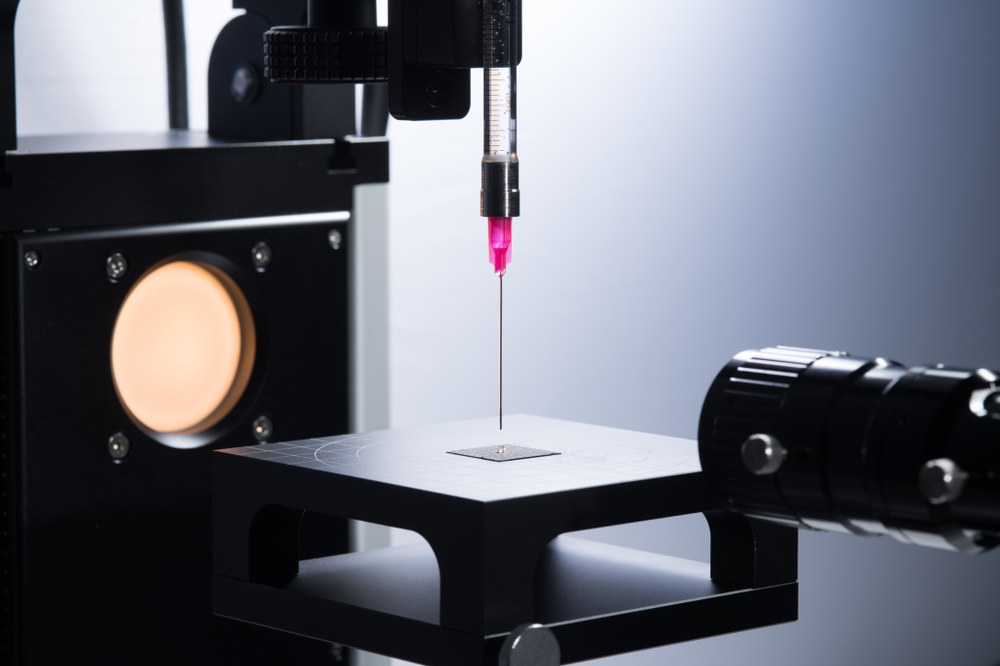

As part of the project, the DLR Institute of Engineering Thermodynamics is developing non-precious metal M-N-C catalysts and sustainable gas diffusion electrodes (GDE) for the electrochemical CO2 reduction reaction.

The innovative, low-cost and resource-saving GDEs will be used in the future in CO2 electrolysis to produce carbon monoxide and complex hydrocarbons - so-called C2+ products. Two overarching objectives are being pursued. (i) The development of electrocatalysts free of critical raw materials through the use of novel metal-nitrogen-carbon structures and multi-metal alloys. (ii) Replacement of the PTFE binder with non-toxic materials free of per- and polyfluorinated alkyl substances (PFAS). Recyclability, economics and sustainability will also be assessed.

In addition to DLR and Covestro Deutschland AG (coordinator), Umicore, TU Clausthal, RWTH Aachen and Ruhr University Bochum are involved as project partners. xemX materials space exploration GmbH is a subcontractor and Freudenberg Performance Materials is an associated partner.

More information is available at the following link: https://materialneutral.info/project/disco2very/

Contact

Prof. Dr. rer.nat. K. Andreas Friedrich

Dipl.-Kff. Sabine Winterfeld