Wedge-shaped disc amplifier

Disc-laser amplifiers are able to achieve high average powers with high pulse energies and ultra-short pulses. This requires dozens of optical elements such as mirrors, which are used for beam folding. On the one hand, this is necessary to image pump radiation several times onto the disc so that it is almost completely absorbed in the laser-active medium.

Brief description

In order to realize the beam folding in the disk particularly efficiently and in a space-saving manner, the concept of the wedge-shaped optical trap is used in the wedge-shaped disk laser.

Applications

Cost-effective and compact laser amplifier for material processing or other applications where high pulsed laser power is required.

Facts and figures

demonstrated until now:

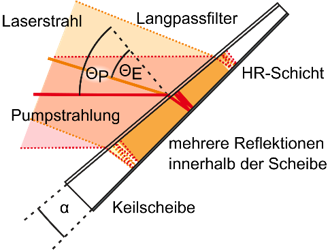

On the other hand, the laser beam to be amplified in amplifiers requires several passes through the disc in order to provide a sufficiently large interaction length for the amplification process. In order to achieve beam folding on or even in the disc, the concept of the wedge-shaped optical trap is used. The angle-dependent transmission behaviour of dichroic thin-film systems plays a decisive role here. The transmission edge of a long-pass filter shifts to shorter wavelengths at flatter angles of incidence.

As shown in the figure, there is an angle of incidence for a monochromatic laser beam at which the angle-dependent long-pass filter (LP) transmits. This allows the beam to pass through the long-pass filter and reach the highly reflective (HR) coated surface behind it.Due to the wedge angle, the beam hits the LP coating again at a smaller angle of incidence after reflection. This has a high reflectivity at this smaller angle of incidence and now reflects the beam back towards the HR coating.The angles of incidence continue to reduce until the path of the beam reverses and the angles increase again. After several reflections, the angle of incidence on the LP coating is large enough for the laser beam to be transmitted again. For a wedge disc amplifier, the area between the two coatings is designed as a laser-active material.