Process Optimisation and Digitalisation Department

The Process Optimisation and Digitalisation Department explores the mapping of real components as digital twins to achieve predictive maintenance and optimise process workflows.

Goals

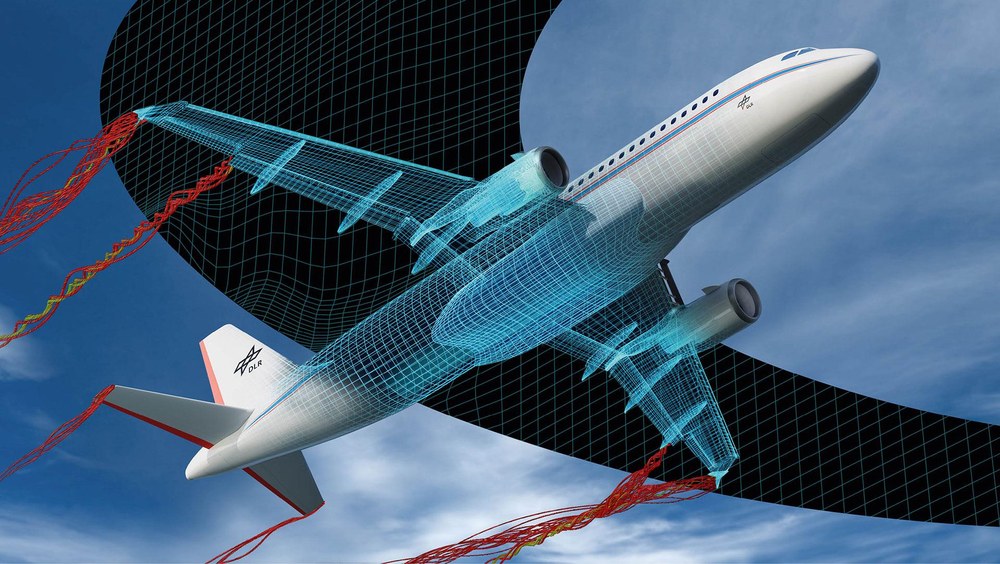

The Process Optimisation and Digitalisation Department focuses its research on predictive maintenance strategies. Continuous health monitoring and the optimisation of current maintenance processes are among the research topics that contribute to the development of innovative MRO methods, with the digital twin concept constituting the core of the research activities. Thorough analysis of the real product and its associated data enables a virtual representation, featuring all relevant attributes, to be generated. The model allows for the recording and processing of collected data, thus providing an efficient and precise interface for further research efforts and a link between different engineering disciplines and stakeholders.

Methods

The main research concentrates on the evaluation of heterogeneous data and experiences collected from the analysis of maintenance, repair, operation and on-board systems. In this way, we can predict when damage, degradation and other conditions that might require maintenance will occur, not only statistically but also for each individual product and its specific properties.

Singular maintenance events are adapted and optimised by means of new technologies to integrate them seamlessly into higher-level process chains. As an example, today’s work-intensive manual documentation and data evaluation methods can be replaced by a fully automated digital workflow, improving the reliability and efficacy of these processes.

The institute’s Application Center MRO provides the means for these research topics to be developed, demonstrated and evaluated in the practical sense.