DLR at JEC World 2016

The German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is showcasing its current research projects in the field of high-performance fibre-reinforced composites from 8-10 March 2016 at the JEC World Composites Show & Conferences in Paris, the leading specialised world exhibition and conference for composite materials. The DLR Institute of Structures and Design and the DLR Institute of Composite Structures and Adaptive Systems, together with the DLR Center for Lightweight Production Technology (Zentrum für Leichtbauproduktionstechnologie; ZLP) in Augsburg and Stade, will offer insights into their wide range of expertise along the entire process chain at the DLR stand (Hall 5a, Stand D65) – from the development of new manufacturing methods and production technologies to solutions for automated production.

Automated application of lightning protection in aircraft construction

The aviation industry is increasingly turning to fibre-reinforced composite materials for the construction of aircraft fuselages. In contrast to an electrically conductive fuselage made of metal, which protects passengers by acting as a Faraday cage, additional measures are needed when these new materials are used. Until now, a special lightning protection layer has been applied by hand using an expensive process. ZLP in Augsburg has developed and tested a solution, together with industrial partners, to apply this lightning protection in a completely automated way. The special laying head being exhibited at JEC ensures that the protective layer is applied without any creases. At the same time, the automated process is characterised by better material utilisation and tighter tolerances.

Process development for thermoplastic components

The aviation industry is also increasingly using thermoplastic components. Thermoplastics are special high-performance plastics that can be shaped when heated and can also be welded. Production uses hot presses, so these are especially suitable for small to medium-sized components produced in large volumes. The DLR Institute of Structures and Design in Augsburg and Stuttgart is conducting research into the development of high-performance thermoplastic structures. The focus is on a holistic approach to a seamless process chain. At its stand, DLR is showcasing a module that could be used as a crash protection element in a helicopter floor structure.

Counter-rotating rotor blades in a lightweight design

To make the next generation of aircraft engines more efficient and environment friendly, the DLR Institute of Structures and Design, together with the DLR Institute of Propulsion Technology, and DLR Institute of Aeroelasticity and Systemhaus Technik, have developed and tested a counter-rotating fan stage for high bypass ratio engines. The shape of these special rotor blades, exhibited at the DLR stand, improves aerodynamic efficiency and reduces noise. By using a new construction method based on fibre-reinforced composites, it has been possible to reduce the weight at the same time.

Solutions for automated fuselage manufacturing

In the course of the MAAXIMUS Project (more affordable aircraft through extended, integrated and mature numerical sizing), researchers at the DLR site in Stade is working on solutions for high-precision, automated and quality-assured manufacturing of aircraft fuselage skins from high-performance fibre-reinforced materials. Important aspects here include the completely automated application of the skin, manufacturing and integration of stiffening elements, adjustment and optimisation of moulding tools and manufacturing processes, and manufacturing full-scale structures. Researchers will show a new process for advanced inductive bonding of stiffening elements, live on the DLR stand.

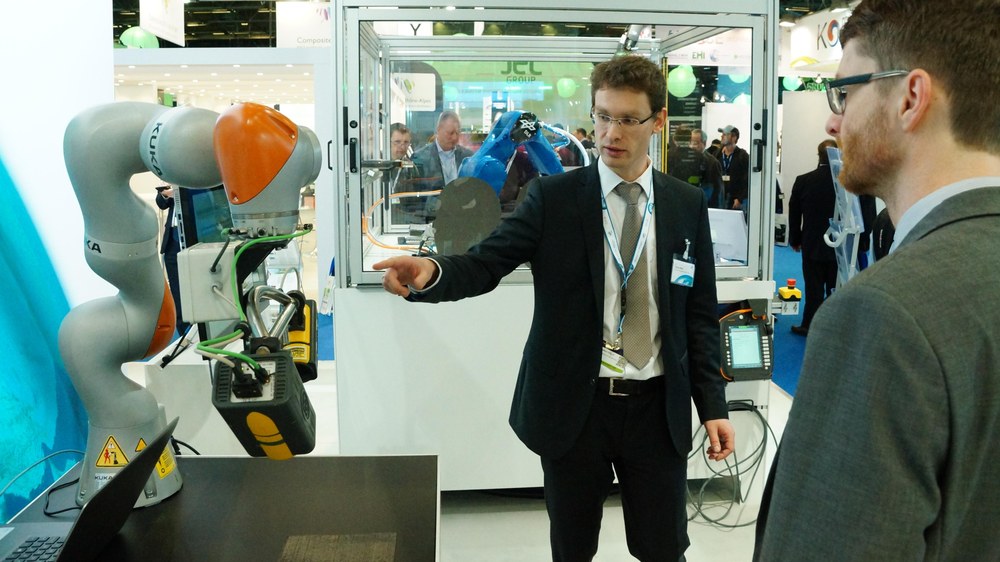

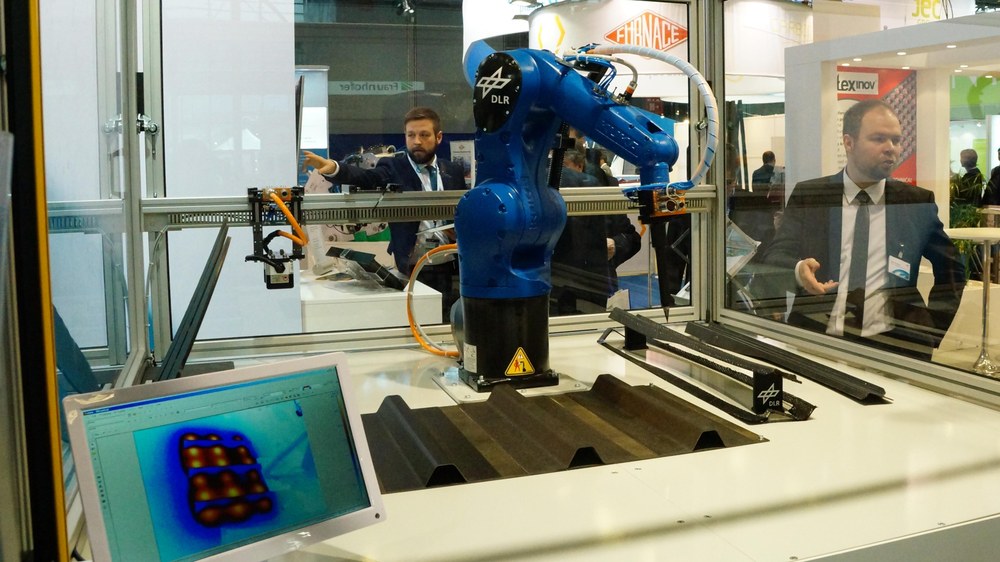

In-situ structural evaluation of production variations

High-technology and complex manufacturing processes are used in the development of fibre-reinforced composite components to satisfy the increasing structural requirements. A major effort is also needed in production, to determine the optimal process parameters. Together with its European partners, DLR is working in the context of the EU ECOMISE project (Enabling Next generation Composite Manufacturing by In-Situ Structural Evaluation and Process Adjustment) to reduce production costs, post-processing, and material and energy usage, while at the same time complying with the high standards required for manufacturing processes and structural properties. To that end, technologies have been developed and integrated as prototypes in existing plants for process simulation, online monitoring, in-situ structural evaluation, and process adjustment. In addition to presenting current research results from the ECOMISE project, DLR has on display a robot arm equipped with a system for automated carbon fibre inspection from the company Loop Technology, as well as the associated mechanical evaluation of production variations.

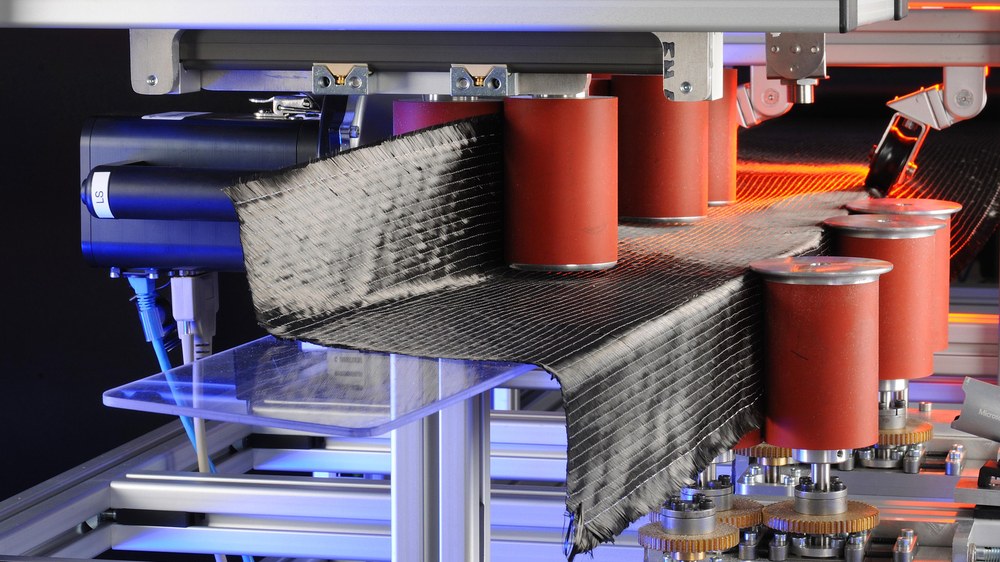

Efficient manufacturing of profile components

Carbon-fibre reinforced profile components are especially suitable for light and rigid structures on aircraft and road vehicles. The patented COPRO technology (Continuous Preforming for Composite Profiles), developed at the DLR Institute of Composite Structures and Adaptive Systems, uses rotating pairs of rollers with variable rotation speeds to continuously and gently shape textile materials into profile components. With the stepless variation of the speed difference and free positioning of the forming rollers, profile components can be produced with adjustable curvature radii and variable profile widths. The automation of this process makes it possible to considerably reduce the costs of the components while improving the quality. The DLR stand will also have this new manufacturing technology on display.