Aeroelasticity of Turbomachinery

As we envision the future of aviation, with 2050 as a pivotal milestone, a significant challenge emerges: reducing aircraft energy requirements by an ambitious 50%. This endeavor demands a comprehensive strategy, encompassing innovative propulsion concepts, streamlined engine integration, and the development of lighter, more efficient engine components capable of operating at extended ranges.

Challenges

As we strive for efficiency, we encounter a hurdle: the increasing complexity of turbine and compressor blade profiles, leading to heightened sensitivity to aeroelastic effects such as flutter or forced response. Modern blade structures, with their enhanced flexibility, are more susceptible to unsteady phenomena like fluid-structure interactions and blade row interactions. Vibrations of high amplitudes pose a risk to both blade aeroelastic stability and structural integrity.

Solutions / Objectives

At our institute, we are dedicated to advancing emissions-reducing aviation propulsion systems and energy-efficient aircraft designs. We aim to deepen our understanding of aeroelastic effects, develop tools for accurate identification and prediction of critical aspects, and validate these tools through targeted experiments.

Our efforts focus on:

- Enhancing the understanding of the physical mechanisms behind unsteady aerodynamic excitations.

- Investigating coupling effects between fluid dynamics and structural dynamics.

- Accounting for aerodynamic and structural nonlinear effects in predicting blade aeroelastic behavior (see Images 3-4).

- Analyzing aeroelastic effects of engine component blades at extreme operating ranges, for example in the vicinity of the compressor surge line.

- Evaluating the aeroelastic characteristics of novel engine concepts, such as boundary layer ingestion.

- Improving engine integration within the aircraft system to mitigate aerodynamic disturbances and reduce the effects of aeroelastic phenomena such as flutter and forced response.

Numerical methods in aeorelasticity

To tackle these challenges, one significant portion of our research concentrates on the development and appropriate selection of advanced numerical modelling methods. Simulations are conducted to analyze the structural and aerodynamic aspects of aeroelastic issues. Accurate methods deepen our comprehension of the involved physical phenomena and offer valuable insights into potential enhancements for optimizing engine components and aircraft system aeroelastic behavior. While accuracy is crucial, we also recognize the need for swift methods during the engine design phase. These methods, though sacrificing some accuracy, significantly speed up the blade design process by facilitating simultaneous and parallel efforts across multidisciplinary fields, resulting in rapid development of safe, highly efficient, environmentally friendly products.

Aeroelastic experiments

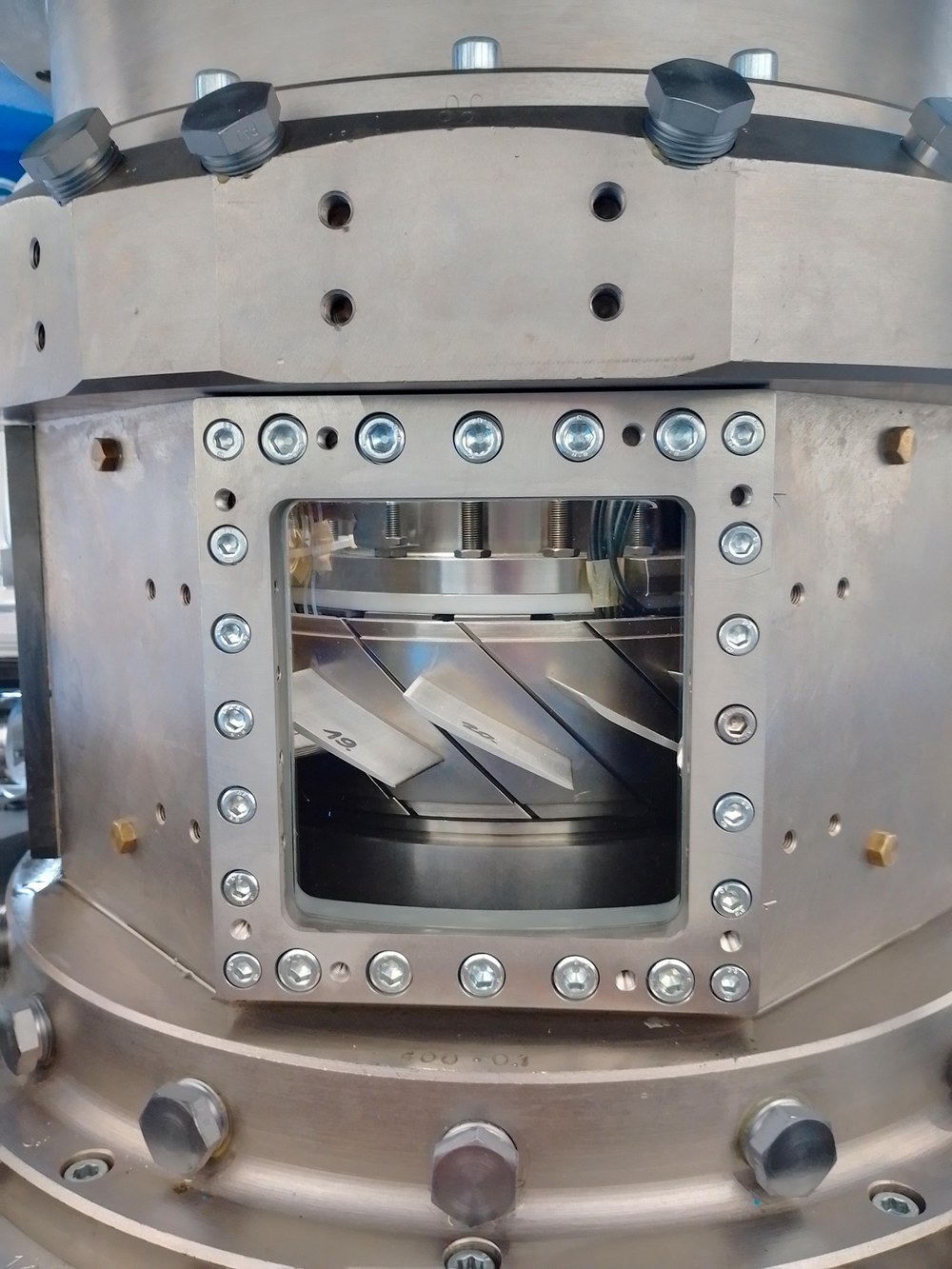

Another portion of our effort concentrates on validating and defining the limits of these numerical approaches. Therefore, well-defined, high-quality and targeted experiments remain integral to our development endeavors. The Institute of Aeroelasticity operates a unique Non-Rotating Annular Test Facility specially tailored for investigating turbomachinery blade aeroelasticity.

This facility serves multiple purposes:

- Gathering high-quality aeroelastic data on compressor and turbine blade rows for comparison with numerical methods and validation purposes

- Enabling the straightforward and fundamental investigation of various aeroelastic phenomena of turbomachinery blades

- Serving as a valuable platform for developing measurement techniques and testing new experimental approaches

Through our combined numerical and experimental approach, we strive to advance the understanding and management of aeroelastic challenges in aviation. Our goal is to contribute to the development of next-generation aviation propulsion systems and aircraft designs, ensuring a sustainable, safe, and efficient future for air travel.