Developing a Real-Time Simulation Environment for Electrical Distribution Grids

MathWorks User Story

With the Networked Energy Systems Emulation Centre (DLR_NESTEC) at the Institute of Networked Energy Systems in Oldenburg, DLR has an infrastructure that is unique in this form in northern Germany. It closes the gap between computer simulations, which only ever deliver results within the programmed parameters, and field tests in the real world, which can be expensive – and sometimes dangerous.

Distribution grids account for around 98 percent of all electrical grids. They connect conventional, but increasingly also weather-dependent energy sources such as wind and solar parks with consumers in the electricity, heat and mobility sectors. In some cases, these consumers themselves become producers, for example through the continuous expansion of PV in residential buildings. In order to research and optimise this interaction, DLR opened the Networked Energy Systems Emulation Centre (DLR_NESTEC) in Oldenburg in November 2019.

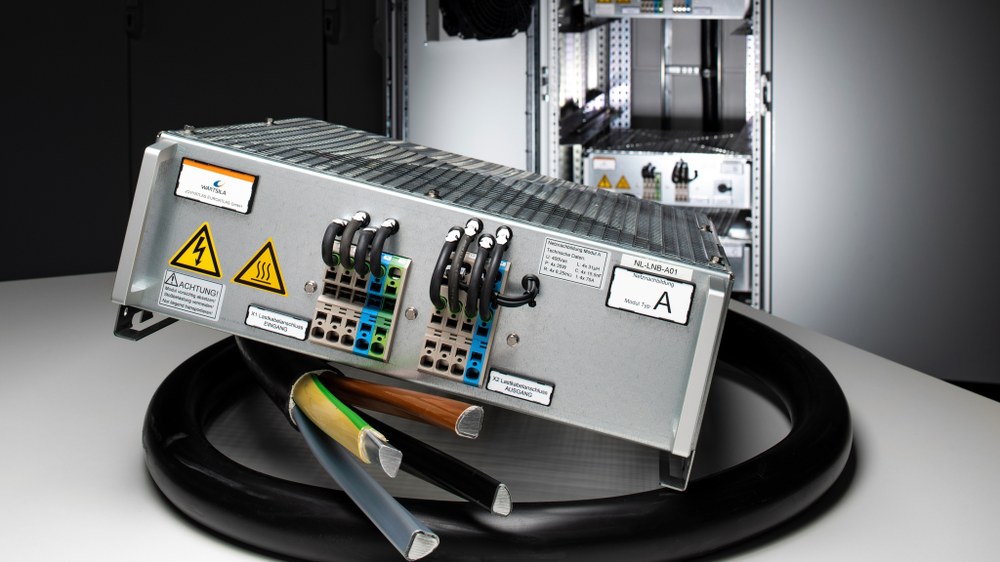

In this way, DLR_NESTEC closes the gap between computer generated simulations, which only return results within the programmed parameters, and field tests in the real world, which can sometimes be expensive and dangerous – for people, for the equipment used and for the security of supply. The DLR_NESTEC lab, on the other hand, uses emulations to create a protected space in that mimics the behaviour of real hardware is tested in a realistically designed environment. In this way, devices such as charging stations, battery storages, heat pumps or photovoltaic inverters can be set up on site and coupled with an environment that emulates a wide variety of conditions for components in real time. In addition to "simple" tests for characterising or commissioning new types of components and systems, the focus is particularly on integration into existing or future supply systems.

The supply of the 180 square metre laboratory complex is ensured via its own 800 kVA connection to the medium-voltage grid. Experiments can thus be carried out independently of the other areas of the institute building. Since everything takes place in isolation, even experiments with extreme loads in DLR_NESTEC do not pose any risk to the outside world. In order to be able to integrate other laboratories, systems or experiments into experiments if necessary, several cables with a transmission capacity of 100 kVA each connect the DLR_NESTEC with other specialised laboratories of the institute.

The infrastructure of DLR_NESTEC is basically available to all research areas of the institute. But its use is also open to external researchers in science and industry: for example, the DLR_NESTEC team works with groups in several other laboratories, both within DLR and at other institutions equipped with special performance hardware. Another advantage of DLR_NESTEC is that it is not necessary to bring the external hardware to Oldenburg, as the laboratory is equipped with a co-simulation environment that allows us to couple two or more laboratories.

A good four years after its launch, the digitalisation of the laboratory represents a consistent further development of DLR_NESTEC: By installing a smart grid operator, algorithms for grid control can be tested and evaluated here in a real environment. With the new control centre, DLR_NESTEC has a test field in which, for example, AI procedures for grid operation management can be researched or also the communication between various market participants for commercial market transactions.

The aim of the laboratory expansion is to utilise the potential of the digitalised energy distribution grid while maintaining a high level of operational reliability. This is necessary to advance the digitalisation of the distribution grids.

The main research fields of DLR_NESTEC: |

|---|

• Converter dominated grids due to shutdown of conventional power plants |

• DC grids and hybrid structures (e.g.: electricity and gas) |

• System services and system stability |

• Operation management strategies based on innovative data sources (e.g. nowcasting) |

• Sector integration |

• Electromobility (HPC, bidirectional charging, system services) |

• Local / decentralised energy management systems |

• Charging strategies in e-mobility |

• Smart Meter, Smart City & Digitalisation |

• Energetic neighbourhoods and incentivisation strategies |

Services (performance, key features) |

|---|

• Real operation in a safe environment |

• System and component tests |

• Coupling of simulations and real components |

• Power Hardware-in-the-Loop (PHiL) & Rapid Control Prototyping |

• Integration of external simulators, components or laboratories in trials |

• Characterisation and modelling of real components |

• Trials with power ratings up to 400 kVA |