ParticlES

As part of the DLR ParticlES project, special methods for optimising battery components are being developed and applied. The investigations focus on micrometre-sized active material particles, which are a basic building block in electrode production and whose properties are decisive for the capacity and performance of battery cells. The processes inside these particles have a direct influence on the material properties and are difficult to access using conventional characterisation methods. For the investigations, the expertise available within DLR in experimental battery research (Department Electrochemical Energy Technology) and in battery modelling and simulation (Department Computational Electrochemistry) is bundled in an innovative approach. By optimising electrochemical single particle measurements, battery materials can be precisely characterised. This information can be used in simulations with customised transport models. The methodology makes relevant processes in the materials accessible and increases the predictive power of the models. The combination of methods enables the optimisation of current and future materials for Li-ion batteries and, in the long term, a design of active material particles tailored to the specific application.

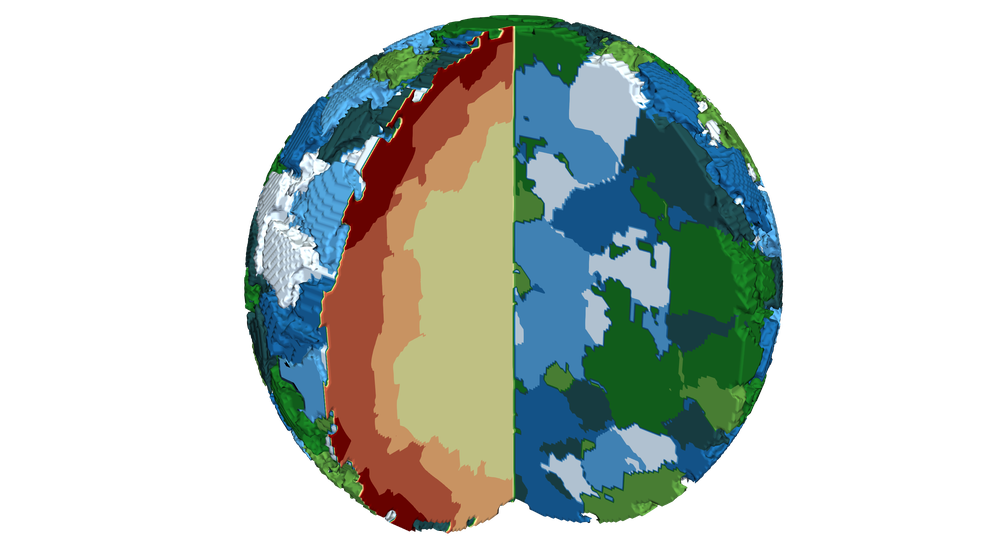

Modelling and simulation at particle level to optimise material properties

The development of active materials currently involves a great deal of experimental effort. The development process can be significantly accelerated through the digitalisation of materials research. Simulations on the microstructure of individual particles allow a deep insight into the operation of the battery and individual limiting processes. The models are parameterised on the basis of the individual particle measurements and relevant material properties are extracted at the same time. In addition to kinetic data, this also includes the influence of transport processes across grain boundaries or electrolyte paths along the grain boundaries. In combination with structure generators, the models allow the virtual optimisation of the materials, adapted to the challenges of specific applications.

Basis for optimising the electrode and cell design

The combination of experiments and simulations at particle and electrode level opens up new possibilities for efficient virtual optimisation from the material to the cell. On this basis, the respective cell chemistry can be optimally utilised and adapted to specific applications. Through virtual cell design, supported by specific modelling experiments, we aim to significantly reduce development time and development costs.

Aim of the project

The work in the project is the preliminary work for the characterisation and simulation of individual active material particles for Li-ion batteries and new cell chemistries, for example sodium-ion batteries. Based on the precise measurements, models are parameterised at particle level, thus laying the foundation for efficient material development.

ParticlES at a glance

Project | ParticlES - Single particle analyses by using experimental methods and simulation |

|---|---|

Duration | 1.1.2022 - 31.12.2024 |

Project participants | Institut für Technische Thermodynamik |

Support | Basic funding of DLR |