CRISP/AGATA

Duration: 2012-2015

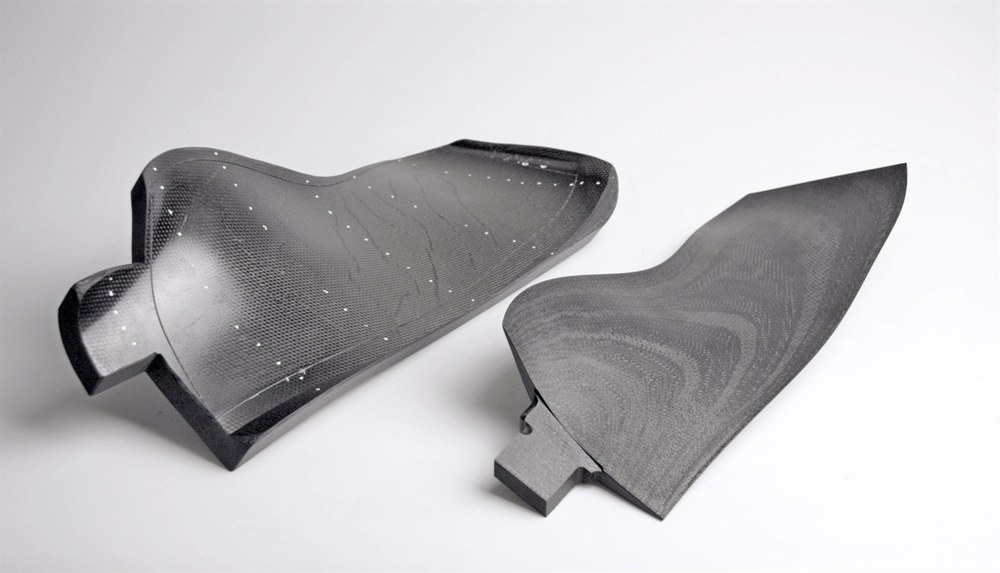

Counter-rotating rotors are a promising but also challenging concept for high bypass ratio fan stages. The multidisciplinary design of the counter-rotating fan stage takes into account aerodynamic, aeroelastic, structural and manufacturing aspects and is being carried out as a close cooperation between the DLR Institutes of Propulsion Technology, Aeroelastics and Structures and Design, together with the Systemhaus Technik Engineering Facility. This made an increase in the level of aerodynamic efficiency, lower noise emissions and reductions in weight possible. The Project includes the demonstration of a novel manufacturing process for rotor blades made of fiber reinforced thermoplastics (CF-PEEK). The design objectives are tested experimentally on DLR’s modern Multistage Two Shaft Compressor Test Facility (M2VP).