Department Space System Integration

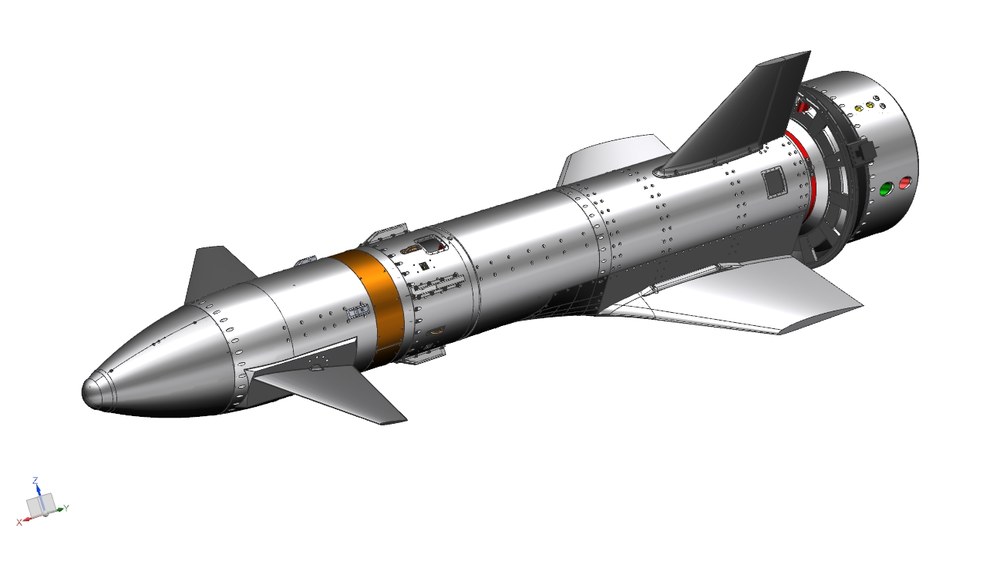

In addition to the temperature resistance of the materials, the minimisation of thermal expansion and expansion management play a central role in the mostly hybrid design concepts of spacecraft. This is particularly true in the field of space propulsion. In the field of satellites, the department is working on innovative approaches for the cost-effective development and construction of highly integrated commercial satellite systems. Technologically, the focus is on new manufacturing processes for satellite structures and propulsion.

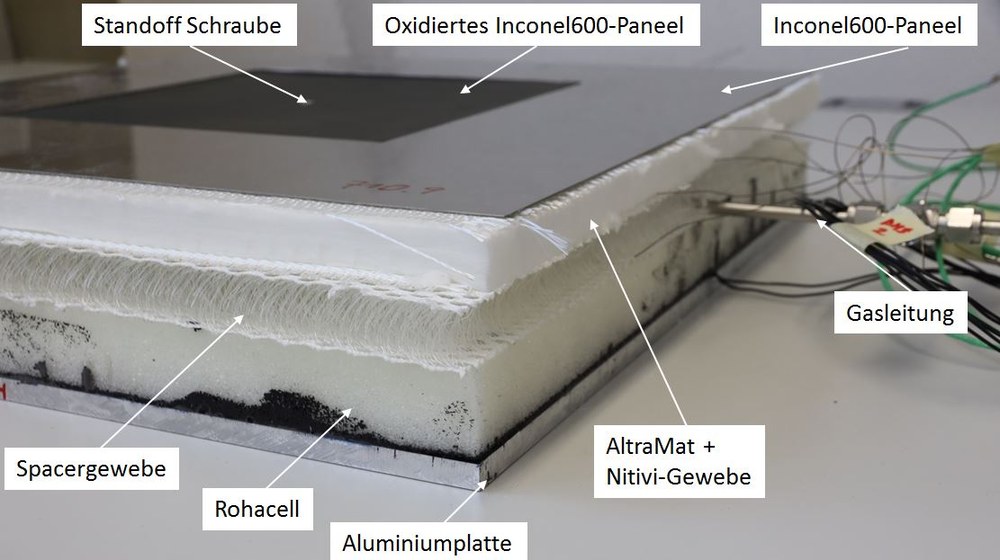

In addition to basic research, the work is predominantly project-oriented and should lead to proven and operational structures. This system-oriented approach leads to the integration of different areas during the development process. Within the department, all necessary disciplines are covered from the preliminary draft to the qualification test. In addition to commercial FEM and CAD software, special simulation tools are available in the area of design and calculation. Research work on actively cooled structural elements is a focal point.

During the production of the corresponding structural components, the competences of other departments of the institute are integrated in addition to our own production facilities. This means that almost all material classes and corresponding manufacturing processes are available for structural design. To qualify the systems, our own testing facilities and various non-destructive testing methods are available. A realistic testing of the structures is aimed at in-flight tests. This usually takes place within joint projects at national and European level and in cooperation with other research institutions.