AeroLight

Duration: 2007-2013

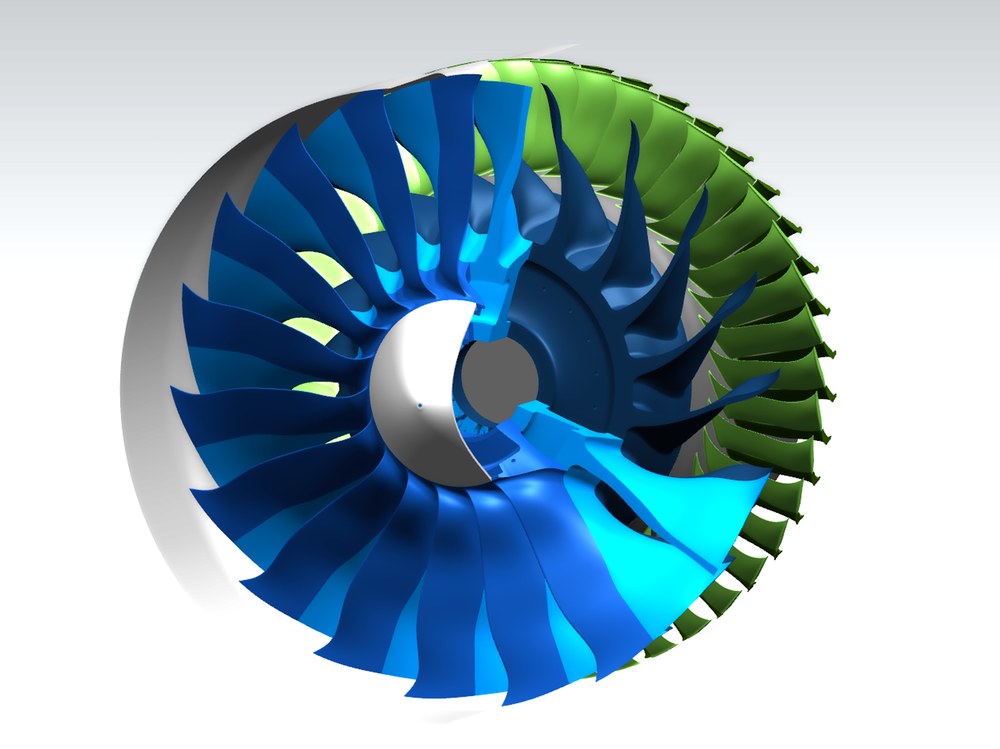

AeroLight is a multidisciplinary DLR project involving the Institutes of Propulsion Technology, Aeroelasticity, Structures and Design and Materials Research, together with the Systemhaus Technik Engineering Facility. Its aim is to use new technologies to design and build a highly loaded compressor stage consisting of a rotor and tandem stator and ultimately integrate this into a test rig. In doing so, the performance level of the compressor can be significantly increased in contrast to existing single-stage configurations. This has been made possible primarily through bringing together the expertise of the participating institutes.

‘AeroLight’ stands for the symbiosis of aerodynamics and lightweight materials, and is intended to reflect the central interdisciplinary nature of the project. An indicator of this is the inclusion of technology developments in the areas of aerodynamics, materials and structures, as well as interaction between these areas.

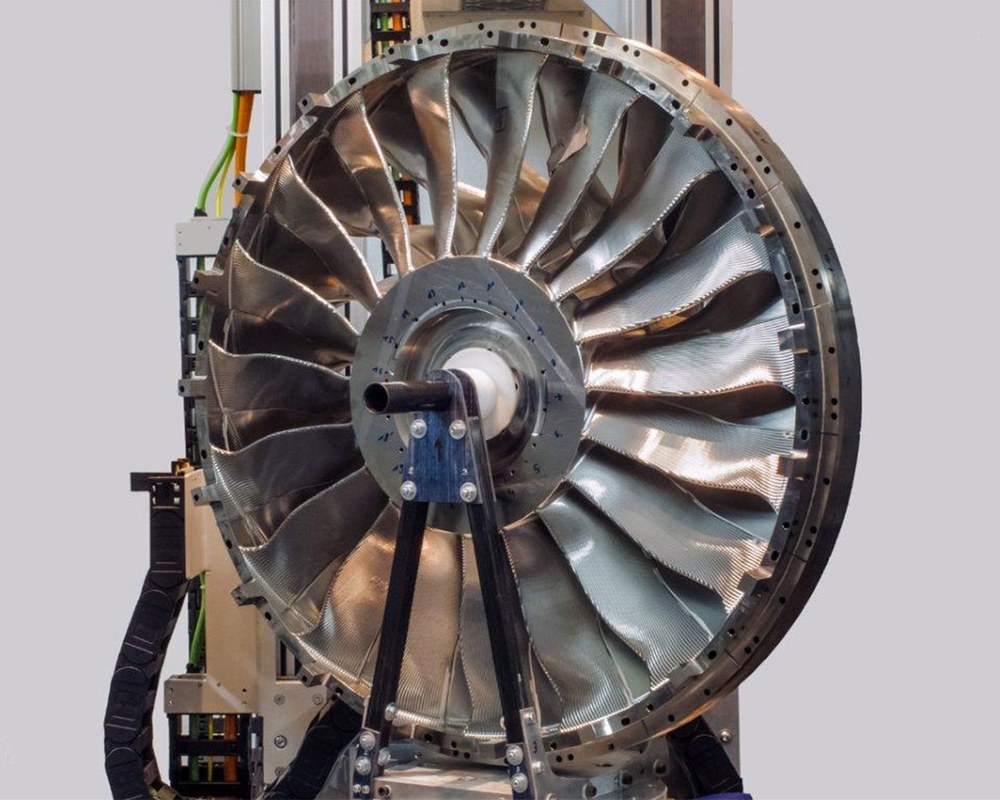

At the core of the project is a new, alternative compressor rotor design that, as a result of its complex geometry, combines individually manufactured segments in a final assembly process. New optimisation techniques are due to be tested on this rotor; in addition, new materials technologies, aerothermodynamic, aeroelastic, mechanical stability and manufacturing solutions will be investigated and evaluated.

Through targeted cooperation with partners in relevant disciplines, complex technical problems can be addressed and resolved throughout the entire process chain. Furthermore, an external industrial partner that is occasionally directly involved in the work packages has been recruited to collaborate on verification and appraisal, and to support the design and manufacturing process. A final demonstration run of the rotor on the M2VP compressor test rig in Cologne is planned to test the predicted performance level using map data and to put the achieved results into practice.

On completion of the project, experiments will be carried out that can provide unique measurement results due to the targeted power density.

As a result, AeroLight contributes to DLR’s strategic core competences and establishes DLR as an independent research group for engine compressors. Furthermore, the system’s capabilities with regard to engine components are expected to be demonstrated by the test rig system.