SAFER² – Sensor and AI Fusion for Enhanced Performance and Reliability

DLR AT-FUV

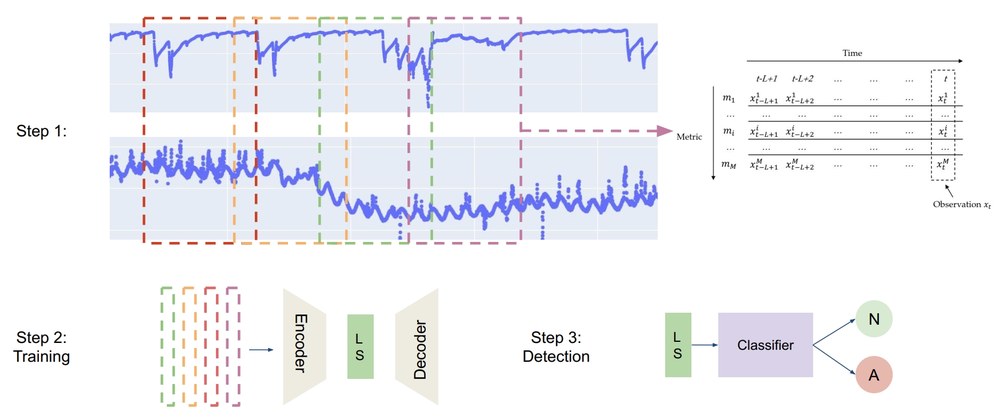

Pham, T.-A.; Lee, J.-H.; Park, C.-S. MST-VAE: Multi-Scale Temporal Variational Autoencoder for Anomaly Detection in Multivariate Time Series. Appl. Sci. 2022, 12, 10078. https://doi.org/ 10.3390/app121910078.

Duration: 2023-2025

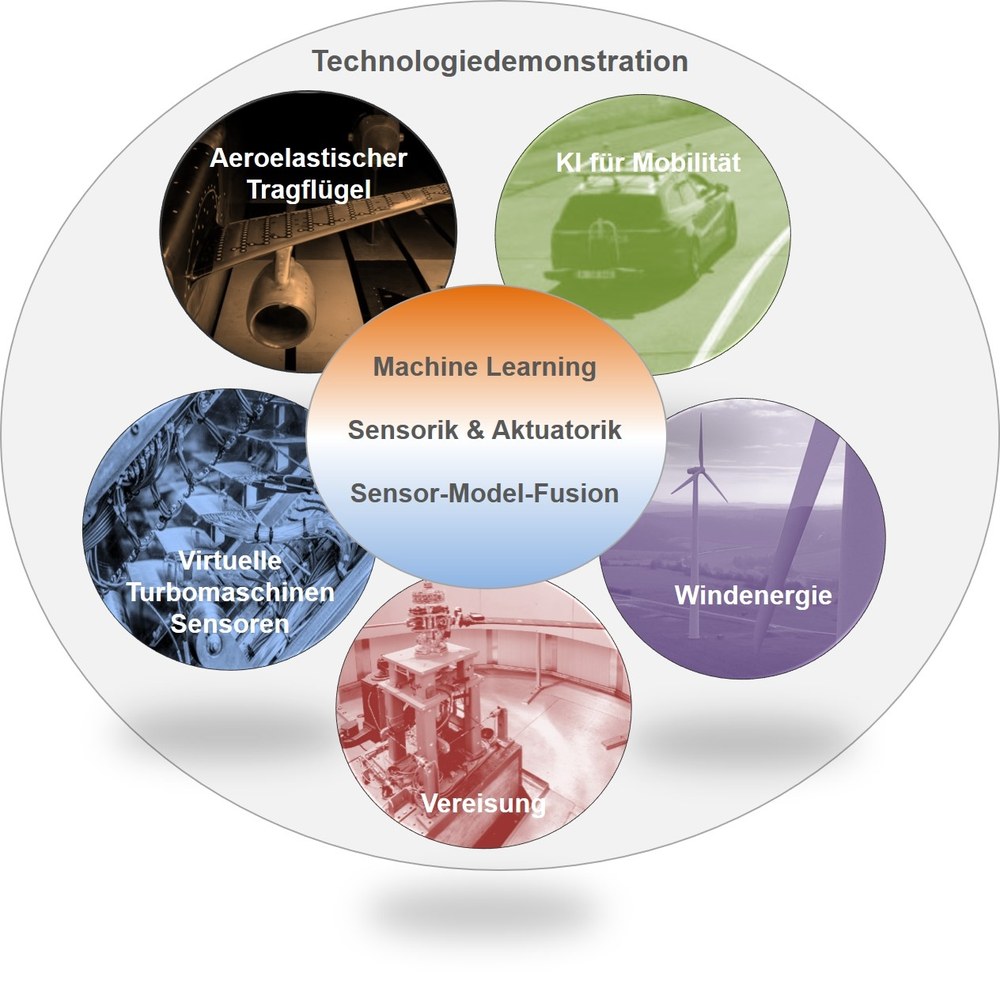

Intelligent sensor systems and their safeguarding for automated and autonomous applications are being researched in the impulse project SAFER². The aim is to integrate sensor technology and artificial intelligence in order to increase both performance and reliability in different application areas. The project will run from 01.01.2023 to 31.12.2025. Led by the Institute of Aerodynamics and Flow Technology (DLR AS), SAFER² incorporates the collaborative expertise of 13 institutes and facilities. With a focus on the DLR fields of aeronautics, energy and transport, synergies are used to fully exploit the potential of technological developments.

A highlight of the project are the five demonstrators, which ensure a hardware-based implementation and demonstration of the developed technologies. There is a special focus on not carrying out independent developments without concrete reference, but ensuring the applicability and relevance of the results.

The five demonstrators are:

- AI for Mobility

- Wind Energy Leaf

- Aeroelastic airfoil

- Icing of fixed and rotary wing aircraft

- Virtual turbomachinery sensors

The main goal is to bring together core competencies from the field of sensor technology and artificial intelligence that are available at DLR to develop fused approaches that are geared towards the goal of "Sensor Data Consistency".

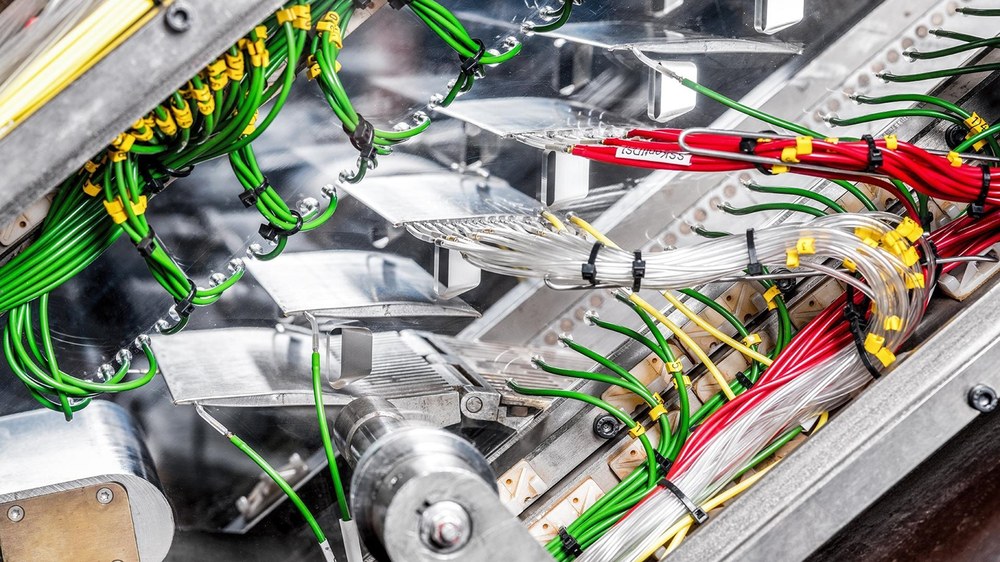

Our Institute of Structures and Structural Technologies (DLR BT) is working together with the Institute of Propulsion Technology (DLR AT), the Institute of Aeroelastics (DLR AE), the Institute for Low CO2 Industrial Processes (DLR DI) and the Institute of Data Science (DLR DW) on the demonstrator "Virtual Turbomachinery Sensors". The focus of the work is on intelligent error and outlier detection as well as reconstruction of compromised sensor data, the development of a "Virtual Sensor" to capture significant system parameters from correlations of the individual physical sensors, with the aim of increasing data quality, test bench availability and system safety.

The transonic grid wind tunnel (TGK) at the DLR site in Cologne, which is in regular and continuous test operation and at the same time offers good metrological accessibility and a wide range of instrumentation, serves as a demonstrator and for data generation. These include pressure sensors, strain gauges (DMS) and optical methods such as laser 2-focus technology (L2F), particle image velocimetry (PIV) and transient schlieren measurement.

The goals of error and outlier detection as well as reconstruction of compromised sensor data are realised in the first development step on the basis of a Multi-Scale Temporal Variational Autoencoder (MSTVAE) and a routine for anomaly detection developed at DLR. In addition to the training, the decisive factor for the quality of the machine learning model is the processing and analysis of the training data, which includes the classification of the occurring anomalies and the artificial introduction of generic error characteristics. Furthermore, the information stored in the training data and concentrated in the latent space, such as physical contexts and correlations, is to be used to reduce invasive sensor technology, to predict the system behaviour by means of a virtual sensor and thus to realise the goals of test stand availability and system safety.