CALLISTO – Cooperative Action Leading to Launcher Innovation in Stage Toss back Operations

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

Objectives

- Development and operation of a technology demonstrator for a reusable rocket first stage (VTVL)

- Acquisition of flight data and scientific knowledge for the development and demonstration of relevant technologies for the reusability of future space transport systems

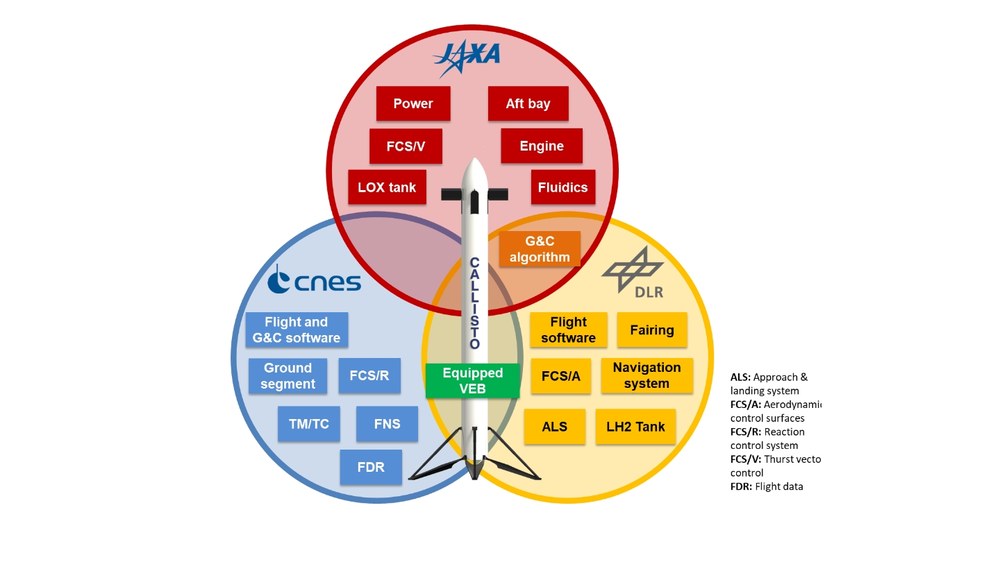

CALLISTO is a joint project between DLR, CNES and JAXA with the goal of developing a reusable technology demonstrator for a vertical take-off and vertical landing (VTVL) rocket stage that will be tested in the scope of an extensive flight campaign. The introduction of reusability for launcher systems could make it possible to reduce launch costs and enhance the versatility of the launcher system. The project aims to improve the knowledge of VTVL rocket stages and to demonstrate the capabilities and technologies required to develop, operate and commercialize an operational, reusable VTVL rocket first stage.

The results of the extensive test and flight campaigns will be used to optimise the design of future reusable space transport systems.

A total of nine DLR institutes across Germany are involved in the project. In the scope of CALLISTO, our institute in Stuttgart is responsible for the development of various sub-components of the rocket. The focus of the project work in the Department Space System Integration is on the structural and thermal design of the mechanically and thermally highly stressed structures.

The responsibilities in Stuttgart include the development of the fairing and, on the structural side, the development of the aerodynamic control surfaces (FCS/A) and the landing legs (ALS), including the thermal protection systems of the structures. The work is carried out in close co-operation with the other institutes involved and includes the design, sizing, mechanical and thermal analysis of the components, test activities at component and assembly level and finally the (partial) integration of the test, qualification and flight hardware.

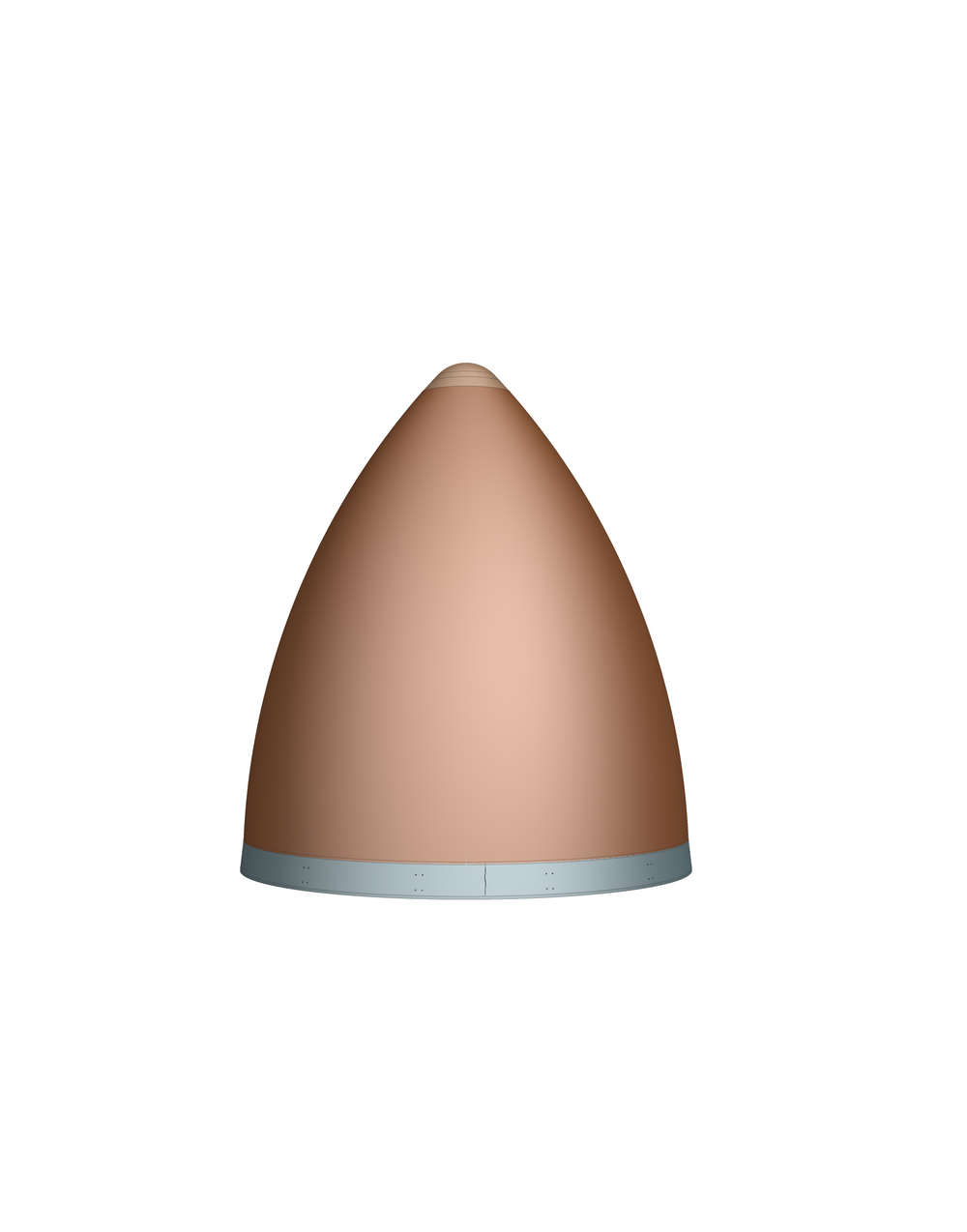

Fairing

The design of the Fairing is based on a CFRP sandwich construction, which is completed with aluminium alloy components at the interfaces. The main task of the fairing is to reduce aerodynamic drag during ascent.

In addition, the fairing tip contains a GNSS antenna. For this purpose, the structure must be permeable to electromagnetic radiation. This is ensured by the use of high-performance plastics.

Furthermore, the fairing is equipped with a cork thermal protection system to withstand thermal loads.

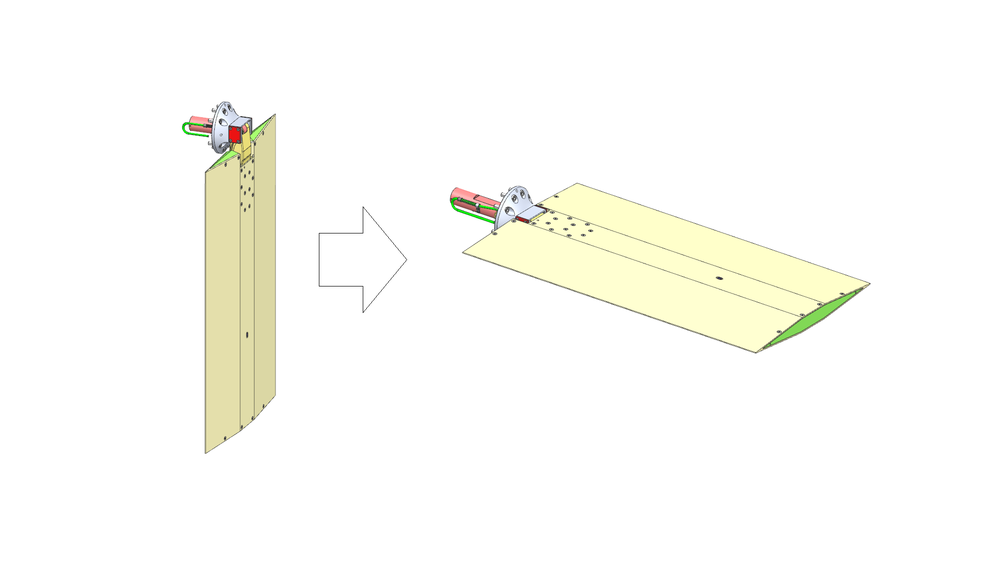

Aerodynamic Control Surfaces (FCS/A)

The aerodynamic control surfaces of CALLISTO are folded during the take-off of the demonstrator and are unfolded at a defined point in time during the flight.

The design is based on a complex system architecture to ensure a safe deployment during flight.

As the fins are subjected to high mechanical and thermal loads, lightweight aluminium alloys are used for the structures.

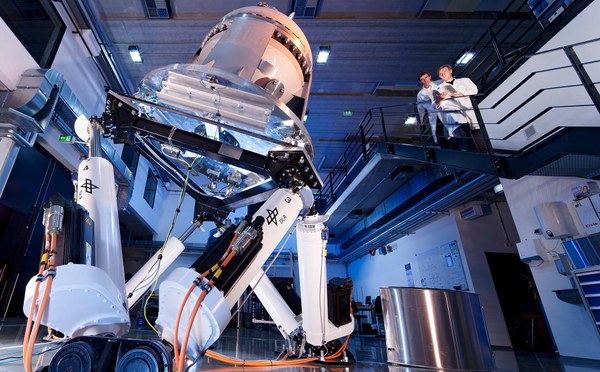

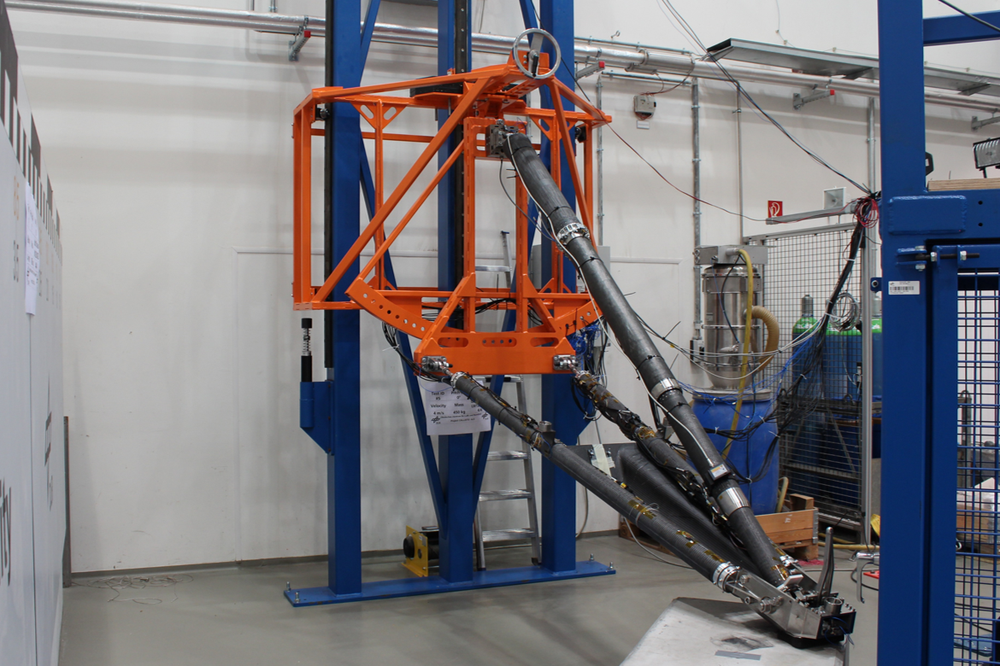

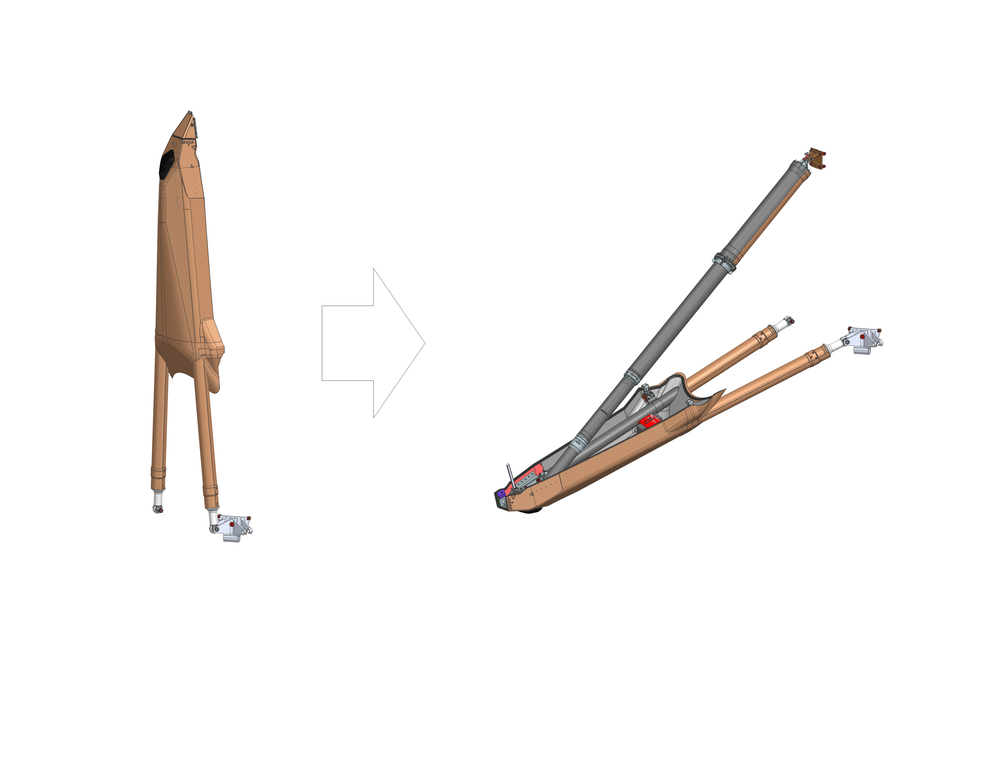

Approach and Landing System (ALS)

The landing legs are also folded in during take-off and unfolded shortly before landing. The design is based on a CFRP parts, which are supplemented with titanium alloy components at the interfaces.

Beyond that, specific coatings are applied to various components of the ALS to ensure a safe deployment.

The landing legs are particularly exposed to thermal stress during the final approach phase and landing and are equipped with a cork TPS for this purpose. In addition, an oxide ceramic TPS is being developed for the first test flights.

Involved DLR-Institutes and Facilities