Joint project DigITecT

The political target of massively expanding renewable energy conversion based on wind and solar power will have a major impact on future power plant capacities, but also on the existing power plant fleet, which must be adapted to the volatile nature of renewable energy sources. In addition to the energy efficiency on the consumer side envisaged in the Energy Research Act, the targets set by the German government can only be achieved if sectors such as transport, households and industry are also electrified to a greater extent in order to make them accessible to renewable energy sources. In addition to the fundamental technical challenges, the robustness of the electricity supply and the affordability of future electricity prices must also be taken into account.

Turbomachinery forms the backbone of numerous storage applications and industrial processes and is also used in processes for the production of synthetic fuels.

The following conclusions can be drawn from the further expansion of renewable energy conversion plants:

The expansion of renewable energies also requires a significant expansion of energy storage capacities to ensure grid stability. This must be done on a scale that far exceeds the technically mature storage technologies available to date (pumped storage, batteries). In addition to mechanical (LAES; CAES) and thermal storage, in which turbomachinery is used without exception for new cycle processes, this also includes chemical power-to-gas storage, for example with green hydrogen.

Thermal power plants must provide reserve energy to compensate for fluctuations in renewables in order to supply power on demand and stabilise the grid. This means that the power plants and their turbomachinery must have maximum operational flexibility.

In addition to the generation of electricity for all sectors, the generation of heat for industrial applications and for the regional supply of district heating networks continues to play an important role. The use of CCGT and CHP plants means that plants with the highest levels of efficiency and fuel utilisation rates are available for this purpose.

The transition from preventive to predictive maintenance will increasingly require the use of highly developed numerical and material technology processes in order to be able to predict the service life of power plant turbines more reliably for the expected highly cyclical operating modes. This requires, among other things, the development of digital twins that can be operated in parallel to real operation and can evaluate deviations online.

MAN Energy Solutions SE

Work packages

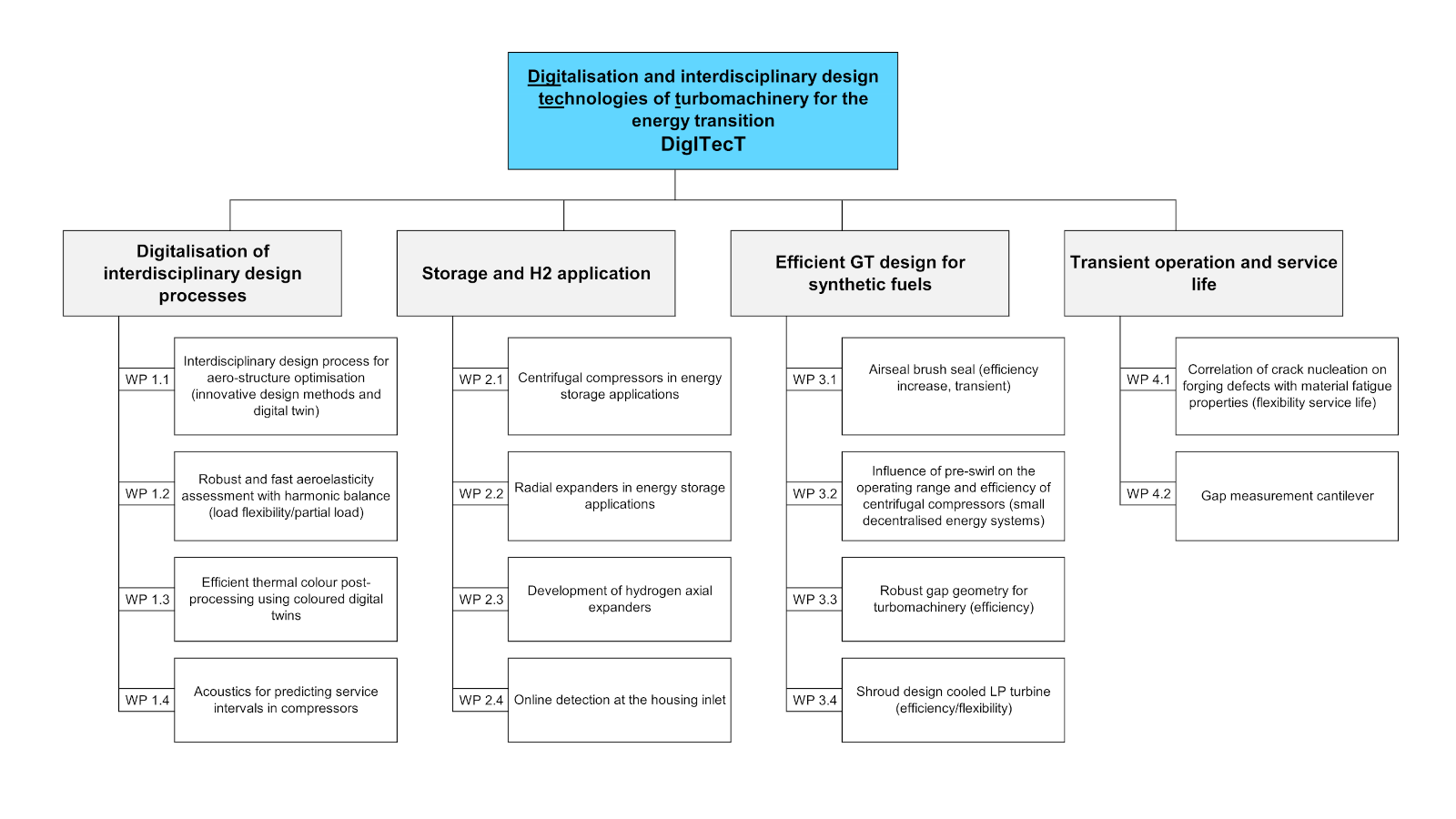

The joint project is divided into four thematically overarching work packages in which the development of turbo components for different areas of application in the new energy mix is being driven forward. The AG Turbo joint project DigITecT addresses the aforementioned aspects and thus contributes to fulfilling the objectives of the 7th Energy Research Programme "Innovations for the Energy Transition".

WP 1: Digitalisation of interdisciplinary design processes

The aim is to achieve end-to-end digitalisation of the development and manufacturing processes for the design and product creation of gas turbines and their components. This will result in significant adjustments to the processes with greater virtualisation and advanced simulation approaches across the entire product creation process. Interdisciplinary simulations are to be used in the early project phases. These topics are addressed in the "Digitalisation of interdisciplinary design processes" work package.

WP 2: Storage and H2 applications

The "Storage and H2 applications" work package is dedicated to compressors and expansion components for applications in storage processes for the future energy infrastructure dominated by renewables and in processes for the synthetic production of climate-neutral fuel gases. For turbines and expanders used in thermal storage cycles, the focus is on expanding the design system for special gas mixtures and hydrogen in the heating and cooling cycles. Among other things, special sealing measures must be taken to prevent the process gases from escaping into the environment. Radial compressors of the future will be calculated and designed using newly developed multidisciplinary design methods.

WP 3: Efficient GT design for synthetic fuels

In order to achieve the climate policy targets, the proportion of electricity generated from highly volatile renewable energies such as photovoltaics or wind energy will continue to increase. To ensure security of supply, storage systems will have to compensate for potential bottlenecks. On the required industrial scale, chemical storage systems such as hydrogen or other hydrocarbons synthesised from electricity at times of overproduction are particularly suitable for this purpose. The "Efficient GT design for synthetic fuels" work package addresses the high degree of flexibility in power generation required for this using GT-based power plants. This leads to frequent, rapid start-up and shut-down of gas turbines in power plants. Small gas turbines, which can be switched on and off as required, are also becoming increasingly important for the flexible adjustment of energy supply. The architecture of small systems differs significantly from large machines in some cases (radial vs. axial compressors) and the larger relative gaps in small gas turbines mean that the required efficiency targets can only be achieved with greater effort.

WP 4: Transient operation and service life

The previous use of gas turbine power plants in the base load range with up to 8,000 operating hours per year is becoming less and less important due to the increasing share of renewable energies. The need for greater flexibility in operation means that significantly more cycles with transient start-up and shutdown processes are required. In the "Transient operation and service life" work package, the influence on gaps and the associated losses in transient operation are being analysed, among other things. The increasing number of cycles favours crack propagation and thus accelerates material fatigue. This can significantly reduce the achievable service life of the gas turbine components. In order to achieve the longest possible maintenance intervals and service life, more precise knowledge and modelling of the damage processes caused by cyclic loading is essential.

Project structure

Facts and figures

Volumen

15.228 k€

Project duration

01.08.2022 - 31.03.2026

BMWK