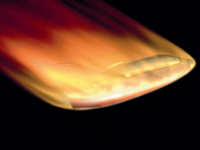

Return Technology - Hot Structures and Thermal Protection Systems

ESA

Robust and damage tolerant concepts for TPS and hot structures, which can be manufactured, installed and maintained at low cost are the mainspring of development. The characteristics of C/C-SiC fiber ceramics under re-entry relevant conditions were examined in detail in a multiplicity of plasma wind tunnel tests in different facilities and flight experiments.

In conjunction with additional oxidation protective layers, e.g. made of SiC or Yttriumsilicate, the surface plasma interaction effects and the passive active oxidation difficulty concerning SiC were examined in detail experimentally and theoretically. In conjunction with experience and data from different flight tests a comprehensive understanding of the partly very complex context exists.

A high level of technological readiness level and expertise regarding the structure concepts could be achieved with the help of a multiplicity of projects and systematic development work. During the EXPRESS mission in 1995 a complete structure component including ceramic load introductions and high temperature insulation was exposed to a ballistic re-entry with extreme heat loads. Within the European FESTIP program at the end of the 90s, an areal full ceramic TPS including ceramic seals and attachment components similar to the functionality of blind rivets was developed and tested. Such technology elements represent a key technology and permit in a so far unique way the simple attachment of panels of a from the hot outer side.

The success of the systematic development work within re-entry technologies is reflected best in the realization of the nose cap for the X-38 of NASA. The development of a load introduction system compensating thermally induced structure expansion, design of a seal system at the intersection of the nose cap to the adjacent TPS as well as the integration of ceramic pressure sensors in the nose shell were special challenges. The nose cap system could be delivered fully qualified for flight in January 2001 to NASA and could be installed in October 2001 to the vehicle.

The main goal with all these developments is to create a robust and damage tolerant complete system that endures as well under operational and economic views. As a consequence this approach leads to fundamental considerations of the shape of future spacecrafts. The dissolution of the present curved forms into wide, flat aereas permits a significant saving in manufacturing and operating costs of a re-usable TPS and led finally to the conception of the hypersonic flight experiment SHEFEX-1 successfully flown in 2005. Design and technologies of a progressive ceramic TPS could be validated as well very successfully with a flight experiment on a Russian FOTON capsule during the mission M2 in 2005. As a result a technology readiness level (TRL) of 7 could be reached.

When it comes to hot primary structures such as the nose cap for X-38 and at present for the European, ballistic re-entry capsule EXPERT, ceramic hot fastening systems are developed, tested and qualified in particular. A further important and function critical subsystem are hot seal systems in the transition area between individual structure segments which make their qualification in a flight test particularly important.

Regarding TPS systems and hot primary structures a high system expertise with comprehensive know-how regarding important key technologies exists.