Components for space propulsion systems

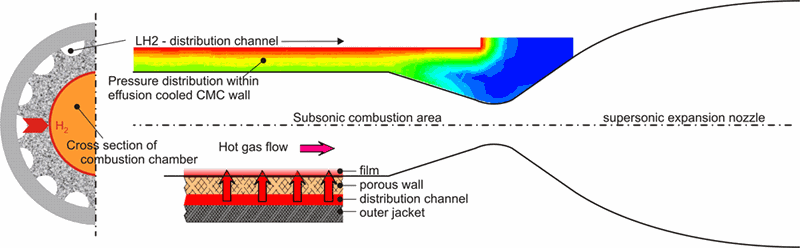

Cross section of an effusion cooled micro thrust chamberA current new development is aiming to realize a new type of a combustion chamber for cryogenic rocket engines (LH2/LOX). Based on an effusion cooling principle the design uses a porous C/C fiber ceramic component for an inner liner and a polymer CFRP composite material for an outer shell which are build up as an integral structure.

Secured by numerous successful test campaigns and basic-oriented scientific work this new research range could be developed in close co-operation with the DLR Institute Space Propulsion in Lampoldshausen.

A thrust chamber of today's technology consists of the regenerative cooled inner copper thrust chamber with numerous cooling channels of extremely thin wall thickness, which is embedded in a solid nickel shell. The new concept plans to replace the heavy metal jacket by carbon fiber reinforced plastic (CFRP) as basic outer shell and to use a porous liner made of carbon/carbon (C/C) instead of copper. Between this liner and the outside CFRP coat cold hydrogen is supplied. Due to a small overpressure on the cooling side compared with the thrust chamber pressure hydrogen penetrates from the outside to the inside through the porous wall material and creates a film cooling layer on the interior wall of the thrust chamber. At the same time heat transferred by convection and radiation to the inner wall, is absorbed by the gas flow and led back into the thrust chamber.

The exclusive use of fiber-reinforced ceramics and plastics leads to several advantages:

Lighter:

Having a density between 1, 3 and 1,6 g/cm3 the composite materials are about 5 times lighter than the metals copper and nickel used today.

Fatigue proof:

Both composite materials possess an extremely small coefficient of thermal expansion, so that despite extreme temperature gradients due to the practically non-existing structure expansion no thermal caused material fatigue effects arise.

Damage tolerant:

C/C is thermally applicable beyond 2000°C in reducing respectively inert atmosphere and proves to be extremely damage tolerant, since it does not possess a melting phase (contrary to metals) and a potential overheating does not lead to a pore closing with damage progress.

Efficiently:

Due to the extremely high yield temperatures of the C/C liner the cooling expenditure can be minimized, so that specific impulse losses are avoided.

Inexpensive:

The concept captivates by its simple, modular basic components and the linked redundant manufacturing processes, whereby a substantial cost saving potential is expected. Therefore in the technology development phase only manufacturing methods are developed, which are scalable on larger, real geometries and permit an automated manufacturing capability.

The physical operational principles could be verified successfully in diverse test campaigns at the test facilities M3 and P8 in Lampoldshausen. The flow characteristic inside the porous wall structures has been analyzed with a numeric simulation tool developped for this purpose and thus a structure optimization is accomplished. In addition to the thrust chamber a new cone injector with porous ceramic structural components is in pre-development; first spraying tests with water/nitrogen demonstrated already a promising fuel vaporization expected due to high Weber numbers and spray visualizations along with it. It is possible that this new thrust chamber and injecting head technologies can be used with re-usable space transportation systems (RLV) as well as with expandable systems (ELV) that may be used either for a lifetime or performance optimization.

A large potential for future applications using the same technology basis opens up. Development work is co-ordinated with the industry within the national research network Propulsion 2010.