Project ATEK

Duration: 2015-2019

AFP Primary Structure for Sounding Rockets

Sounding rocket, CFRP, thermoplastic AFP, in-situ consolidation, Project ATEK

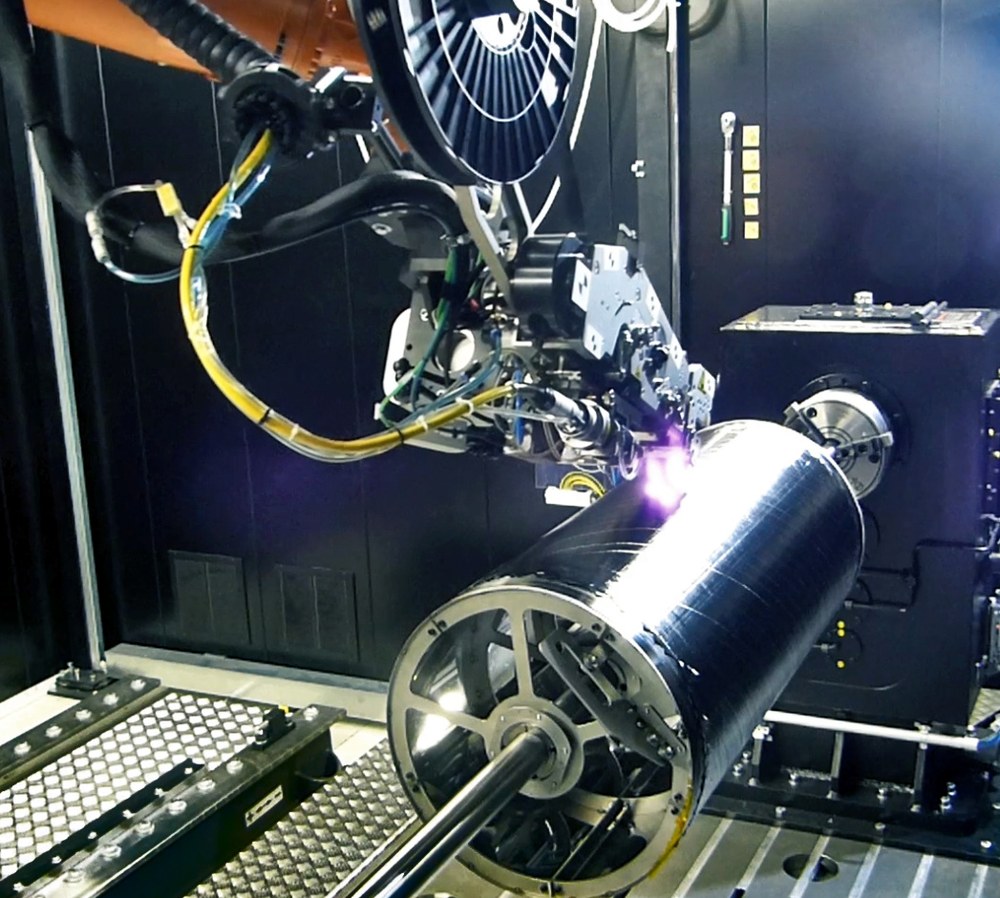

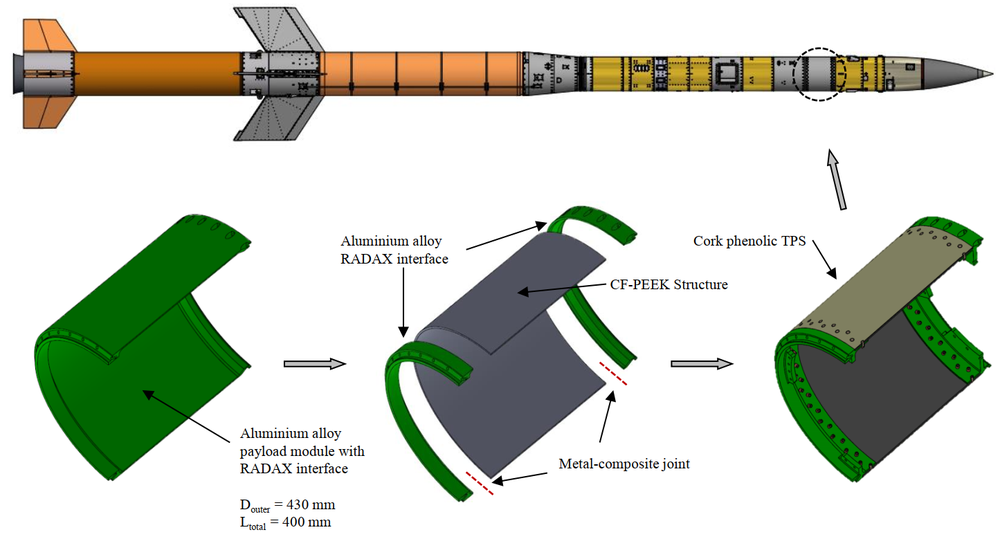

The Institute of Structures and Design in Stuttgart developed a sounding rocket hybrid payload structure composed of aluminium Radax interfaces and a carbon fiber-reinforced thermoplastic (CF-PEEK) cylindrical Structure. This structure was manufactured in-situ at the Automated Fibre Placement (AFP) facility in Stuttgart. Unlike many contemporary thermoplastic parts produced using AFP technology, this structure required no post-consolidation process to ensure structural integrity. This single-step (in-situ) manufacturing method has long been a target in the thermoplastic community, eliminating expensive and time-consuming vacuum-bagging processes.

Operational loads are transferred to the structure via HI-LOK screw rivets, with qualification testing under compression, bending, and shear conditions having been successfully completed in 2018.

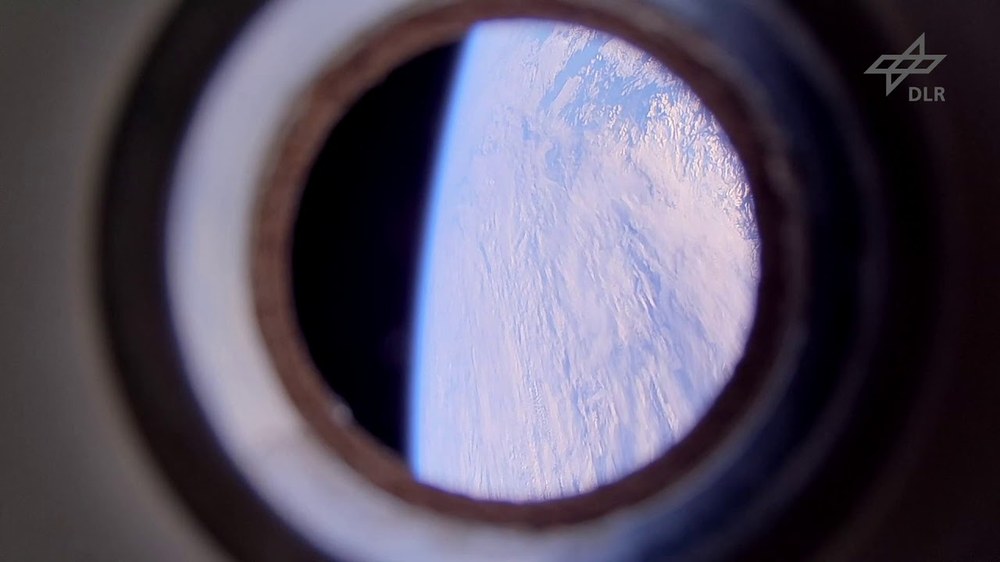

The ATEK flight experiment was successfully launched on 13th July 2019 from the launch site Esrange in Kiruna and provided valuable flight data. The payload reached an apogee of approx. 240 km and landed approx. 500 seconds after the take-off 67 km from the launch site. The payload was decelerated in the late subsonic flight phase using a parachute to avoid a hard impact on ground. The Health Monitoring System provided measurements of the aerothermal and mechanical loads on the hybrid payload.

Video: MIssion ATEK

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.