Adjustment ring for compressor guide vanes

Duration: 2012-2016

The hybrid adjustment ring developed at the Institute of Structures and Design is based on a lightweight hybrid adjustment ring for which a patent application was submitted in 1995; it is used to synchronously adjust guide vanes in the high-pressure compressor which can be found in aircraft engines. With the participation of BMW Rolls-Royce (RRD), Rolls-Royce Great Britain (RR), and a mid-sized company, this ring was developed and tested by the year 2000. The issue of hybrid adjustment rings continues to be of importance today.

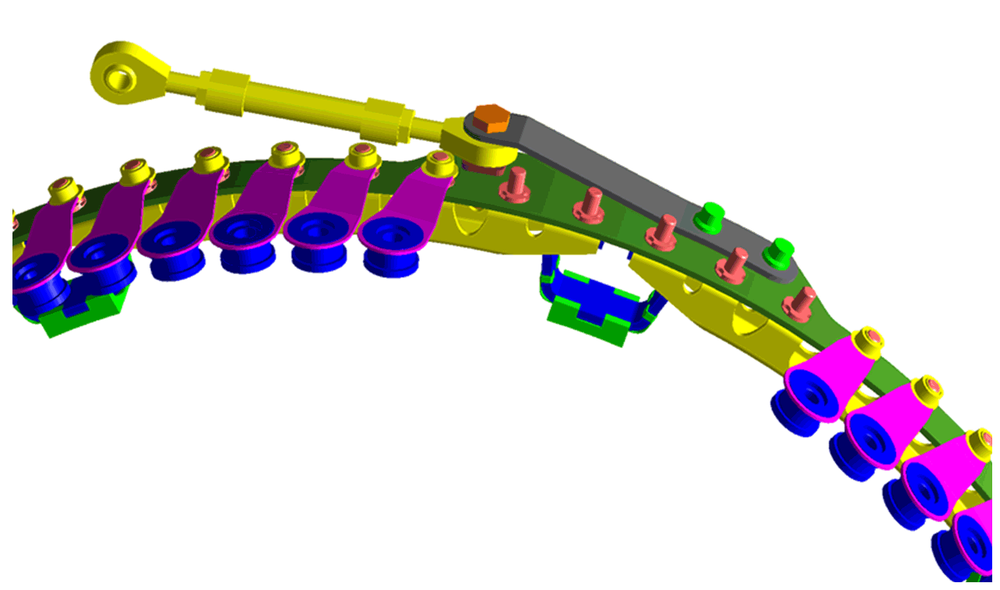

The hybrid structure developed is based on a combination of a carbon-fibre reinforced, high-temperature-resistant composite ring with aluminium connecting elements. With this material pairing, a thermal structural expansion coefficient can be guaranteed that ensures thermal elongation compatibility with the compressor housing onto which the ring is mounted. Functionally integrated lightweight construction prevents the weight of additional elements interfering with the substructures. This happens when the connecting elements, in their secondary function, transfer the movement of the ring to the adjustment levers that are directly connected to the stator blades.

The hybrid ring system is distinguished by its low structural weight, which is reduced by almost 50 percent in comparison to the titanium-based system in use since 1995. In addition, the improved functionality can be used to achieve higher adjustment accuracy as smaller gaps can be achieved during the thermal transition state. The costs have been reduced in comparison to the former design as well. There are now metallic adjustment rings that enable further cost reductions. The structural concept was adopted in the RRD portfolio for adjustment rings in future engines following completion of the development work.

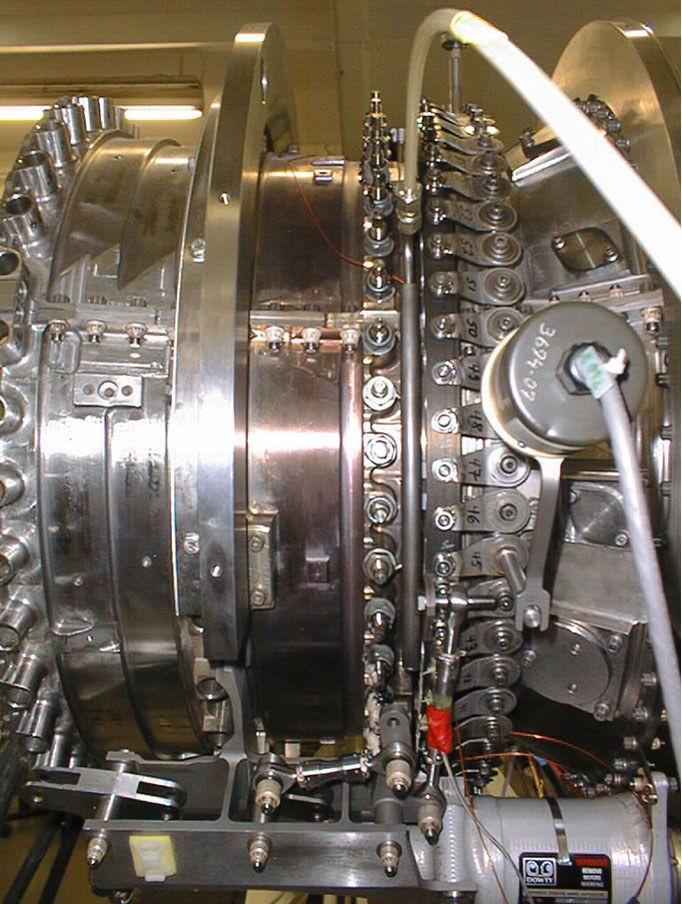

Verification of the rings was first carried out on a test rig at RRD in Oberursel, where the structural advantages were apparent. After an assembly process test at RRD came integration into an engine core that was also successfully tested using the altitude test facility at the Institute of Aircraft Propulsion Systems in the University of Stuttgart.

In recent years, hybrid adjustment rings have gained attention – their increased functionality in the form of more precise adjustment of the guide vanes is expected to contribute to making the flow in the annular channels more homogeneous. This should reduce flow disturbances that excite vibrations in the sensitive blisks. In the E-BREAK (Engine Breakthrough Components and Subsystems) European project, the Institute of Structures and Design is working with partners on adapting the system to modern engines. This structural component is an illustrated example of the process chain – from idea to component – within the Institute.

In the E-BREAK project under the 7th EU Framework Programme, the concept of an ‘Engine Breakthrough Technology’ ready for series manufacturing and testing was further developed and worked on with a partner in industry, in compliance with the levels of quality assurance.