Demisable Joints for High Altitude Break-up

As the number of manmade objects in Earth orbit increases exponentially, the sustainable use of space has been addressed by many authorities and communities around the world by imposing guidelines for space debris mitigation. United Nation member states defined the problem as a “concern for all nations”. The space sustainability is a multidisciplinary approach, which should be tackled both on the technology and legal level.

Our research at DLR Institute of Structures and Design addresses sustainability in space in the technical field. To achieve sustainability in space missions, it is crucial that we no longer pollute and we actively clean up the debris we are leaving behind. While circular economy solutions for space applications are currently in development, ESA Debris Mitigation Guidelines still suggest that Design-for-Demise is the preferred way to dispose of hardware at the end of a space mission as a quick solution.

We work on high-altitude break up of satellites upon their end-of-life by the help of demisable primary structure joints and topology optimized secondary structure elements. This approach suggests that the primary structure of the satellites disintegrate at a higher altitude than they would normally do and hence, have more time to burn away during the hypersonic atmospheric entry.

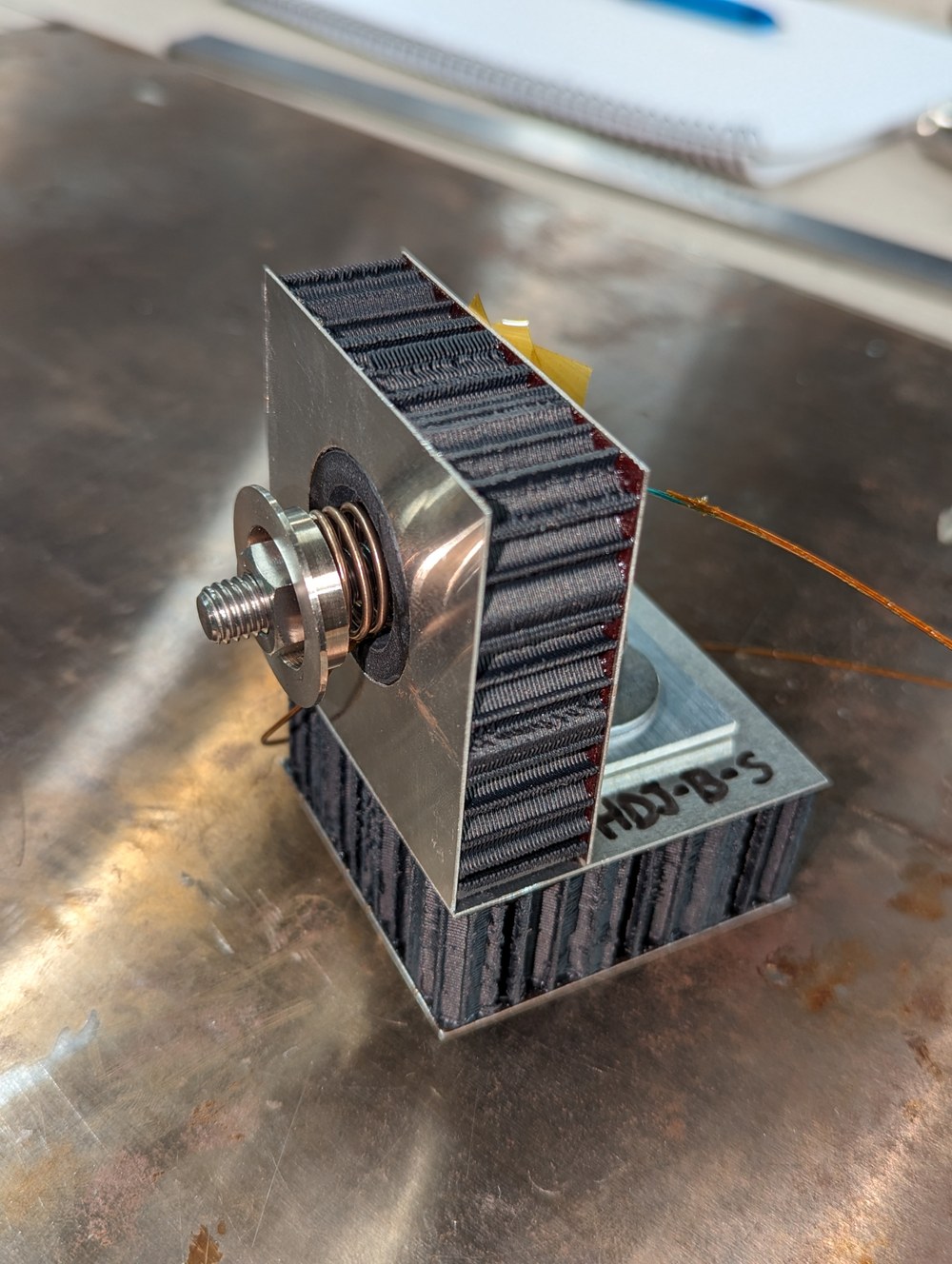

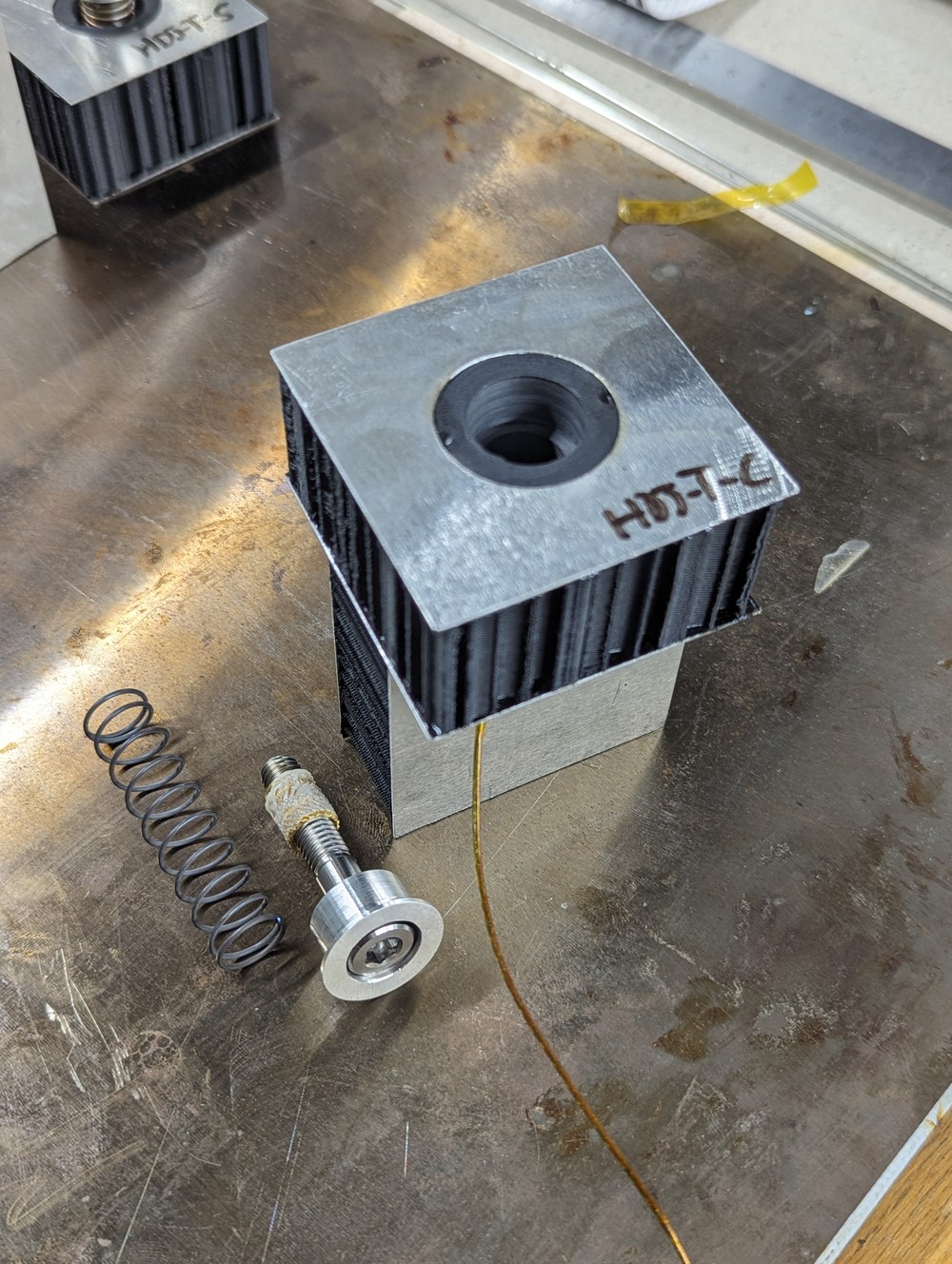

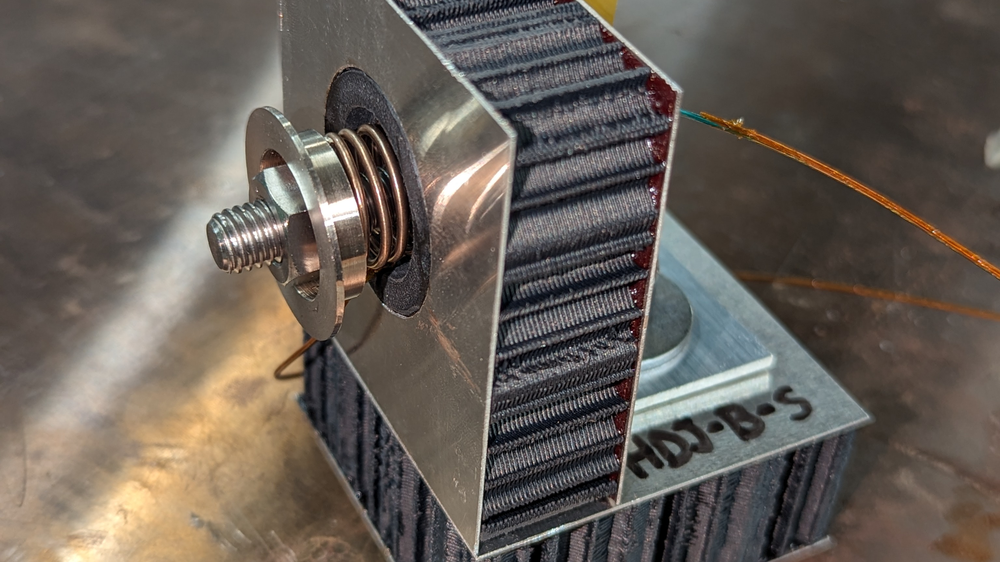

The demisable joints presented here are made of 3D printed PEEK and PEI materials reinforced with carbon fibers. There is additionally an embedded spring mechanism made of shape memory alloys. A passive mechanism is chosen to avoid the risk of any malfunctioning of active onsets. This hybrid self-activating mechanism ejects the attached satellite sandwich structures when the outer surface of the joint reaches temperatures between 200-250°C. These temperatures correspond to an altitude above 110 km. A LEO satellite disintegrates around 80 km if no additional separation mechanism is onboard

This high-altitude break-up allows the primary structure of the satellite to fly away from the satellite bus and exposing the inner components to plasma, which are harder to demise. Overall, we reduce the risk that the satellite components survive the atmospheric entry and pose threat to living beings or infrastructure on Earth.

The demisable joints with bracket allows not only a 90° connection but a range from 45 to 150°. They are also adaptable for sandwich panels as thin as 20 mm or thicker up to 40 mm depending on the satellite requirements. For plates or sandwich panels that are thinner than 20 mm, a different design is currently being developed within DLR TEMIS-DEBRIS project. This new design is also 3D printed and has a self-activating spring mechanism.

Demisable Joints - Design-for-Demise

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.