Energy question of the week: Why do solar power stations also need so much water?

A lot of water for cooling

Solar-thermal power plants, like those operating in Spain and the USA, cannot work without efficient cooling. Steam, superheated to several hundred degrees Celsius, is used to drive a turbine, which in turn drives a generator. The efficiency of this process (the Clausius-Rankine cycle) is inversely proportional to the pressure downstream from the turbine, since lower downstream pressure generates suction that draws the steam through the turbine faster. The system designer lowers the downstream pressure by cooling the steam exiting the turbine, which reduces its volume. The steam pressure at the turbine inlet is around 100 bar, compared to less than 0.1 bar at the outlet.

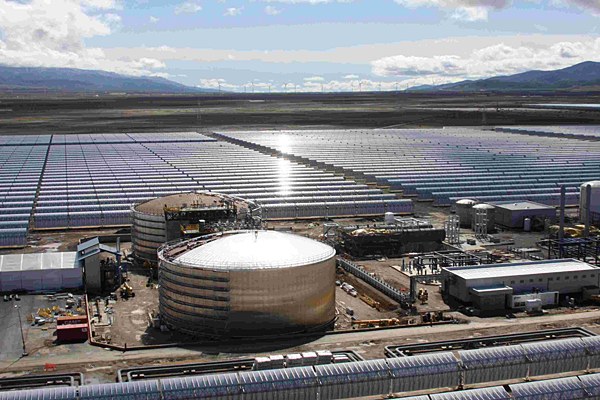

Andasol 1: The Spanish solar power plant uses wet cooling and is equipped with 500,000 square metres of mirrors. Credit: Solar Millennium AG.

Dry cooling for desert power plants

Cooling towers are used to discharge the heat generated by the condensation of steam in coal and nuclear power stations to the environment. A typical solar-thermal power station using wet cooling towers consumes about 3800 litres of water to generate 1000 kWh of electricity. In power stations in Andalusia in southern Spain, this water can be supplied by rivers or existing water supplies. But in deserts, even where such infrastructure might be feasible, it would be very costly.

Researchers at the DLR Institute for Technical Thermodynamics are searching for an elegant solution to this problem in Cologne, in Stuttgart and at the Spanish Plataforma di Solar research centre, and analysing the effectiveness of dry cooling for solar-thermal power stations, with the aim of reducing water consumption by 90 percent. A continuous airflow can be used to cool and condense the steam. The air cooler is composed of hundreds of fins that are heated by the steam and cooled by fan-driven air from outside. The researchers are evaluating the operation and environmental conditions of numerous locations, from Morocco to the United Arab Emirates, for this type of dry-cooling solution.

Although this is an expensive solution and power stations equipped with it cannot achieve the same efficiencies as conventional water-cooled installations, it is an important step towards large-scale solar power generation in desert conditions. DLR researchers estimate that electricity generated with this technology would be three to ten percent more costly, but dry-cooling solutions will be essential to desert power generation projects such as the DESERTEC project.

The DLR Energy question of the week in 'The future of energy' Year of Science

The Federal Ministry of Education and Research (BMBF) has given the Year of Science 2010 the motto 'The future of energy'. For this reason the science journalist Jan Oliver Löfken will this year answer a question on the subject of energy in his blog each week. Do you have a question about how our energy supply might look in the future? Or do you want to know, for example, how a wave power plant works and how it can efficiently generate electricity? Then send us your question by email. Science journalist Jan Oliver Löfken will investigate the answers and publish them each week in this blog.

Image above: Parabolic mirror with absorber pipe. Credit: DLR.

Tags: