Intelligent wheels – safe locomotion on unknown terrain

Driving under low gravity conditions represents a significant challenge for the Martian Moons eXploration (MMX) rover. The gravitational pull of Phobos is about two thousand times less than that of Earth. As a result, locomotion must be slow and careful to ensure that the rover does not lift off of the surface – a sporty 'wheelie' on Earth could be fatal on Phobos. Another challenge is the soft sandy soil on Phobos – due to the low gravity, it is looser than the soil on Earth and this could cause the wheels to sink deep into the material.

The researchers at the DLR Institute of System Dynamics and Control were tasked with developing wheels for the rover that can provide optimal traction, while remaining extremely light and stable. As early as the landing, a lot is demanded of the wheels. During its first approach to the Phobos surface, the rover will be uncoupled from the MMX exploration module at a height of approximately 50 metres and fall to the surface, likely bouncing several times upon contact. During landing, the wheels have to gently cushion the rover before proving themselves in the challenging terrain

Creating an intelligent wheel using simulations

To cover as many technical functions as possible with as few components as possible, the researchers used state-of-the-art simulation and optimisation methods. The elements of the wheel that improve the tractive force also help the wheel to better withstand the loads during take-off and landing, for example. This made it possible to develop a stable and compliant wheel that intelligently prevents excess stress.

To further improve the traction, the researchers carried out calculations using particle simulations that replicate the sand on Phobos. The team was immediately confronted with determining whether driving on Phobos is possible at all. Through complex simulations, they determined that it is indeed possible. The MMX wheel was designed to be suitable for a wide range of sand types, since little information about the exact ground conditions will be known before landing. For this purpose, 'worst-case' soils – the most difficult conceivable cases – were also created and simulated as virtual sand types.

Video: Model of the MMX rover during tests on the test bench

Your consent to the storage of data ('cookies') is required for the playback of this video on Quickchannel.com. You can view and change your current data storage settings at any time under privacy.

The analysis of different movement scenarios, such as gradients, transverse travel, starting and braking, played an important role, as each situation creates its own requirements. High-performance computing was required to develop and run the elaborate simulations within the mission’s tight schedule. In doing so, the researchers succeeded in finding an innovative wheel geometry that enables traction on Phobos.

The MMX wheel – robust and lightweight

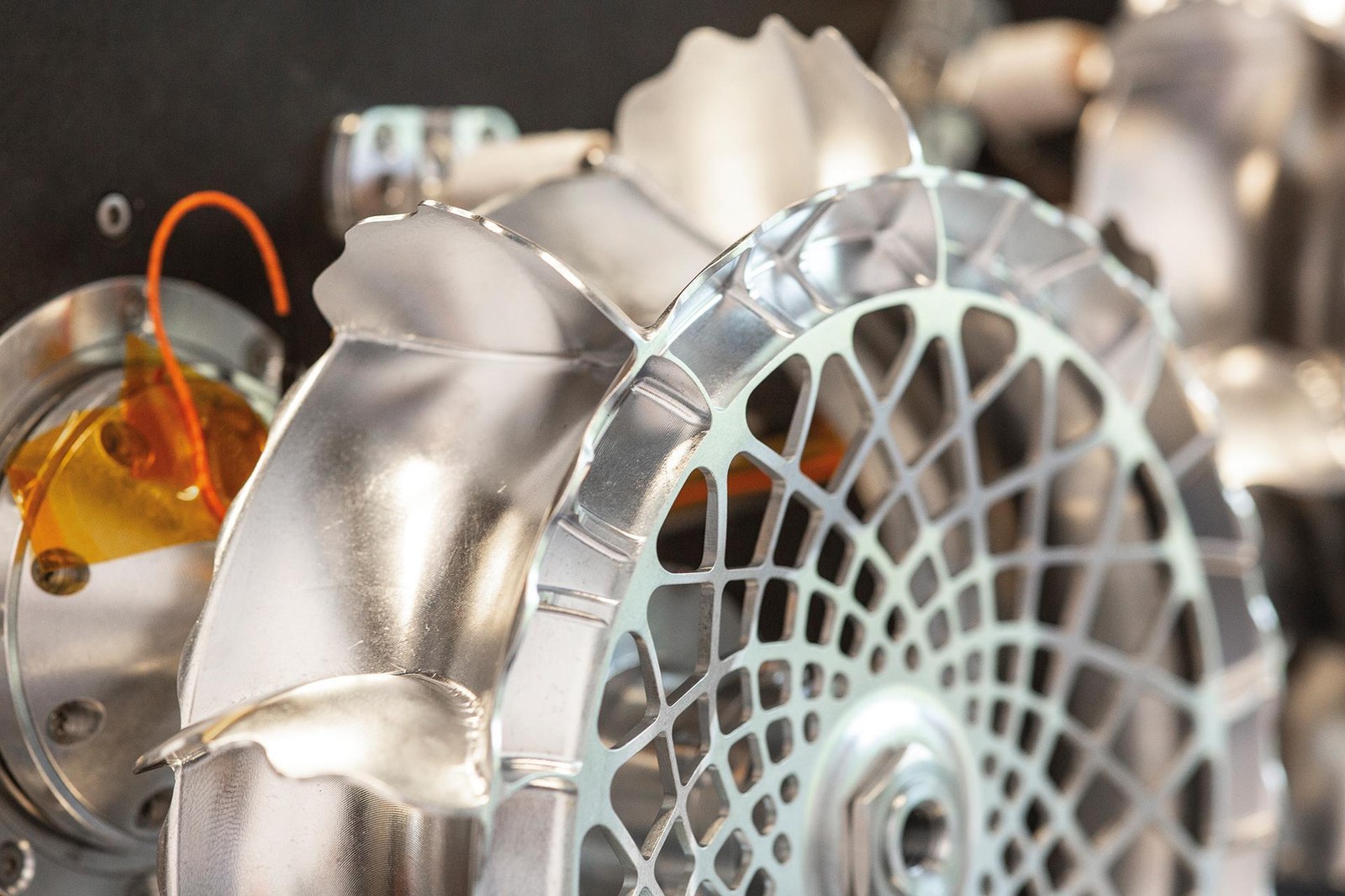

Nine blades on each wheel, also called ‘grousers’, provide the necessary thrust on sandy and loose terrain, but they can also be used to drive on a hard surface. The inwardly curved tread minimises sinking while allowing sufficient grouser surface to maximise traction. The laterally asymmetrical profile of the tread facilitates point-turning – turning on the spot.

Compared to previous rover wheels, the MMX wheel is far less massive – one wheel has a mass of just 190 grams. With a diameter of 214 millimetres and a width of 53 millimetres, such a mass can only be achieved using a thin wall thickness of less than one millimetre. The spoke structure was created with the help of topology optimisation, a computer-based process that calculates the best possible basic shape for components under mechanical load. The mesh-like structure also provides the necessary stability – if the rover were to land sideways on sharp rock and a spoke element were to break, the rover could still continue on its way and the mission would not be endangered. To be able to achieve the necessary strength with the thin walls, a high-strength aluminium alloy was used. Further stiffeners in the wheel structure serve as anchor points for a 'Hold Down and Release Mechanism', which holds the wheel and the leg in position.

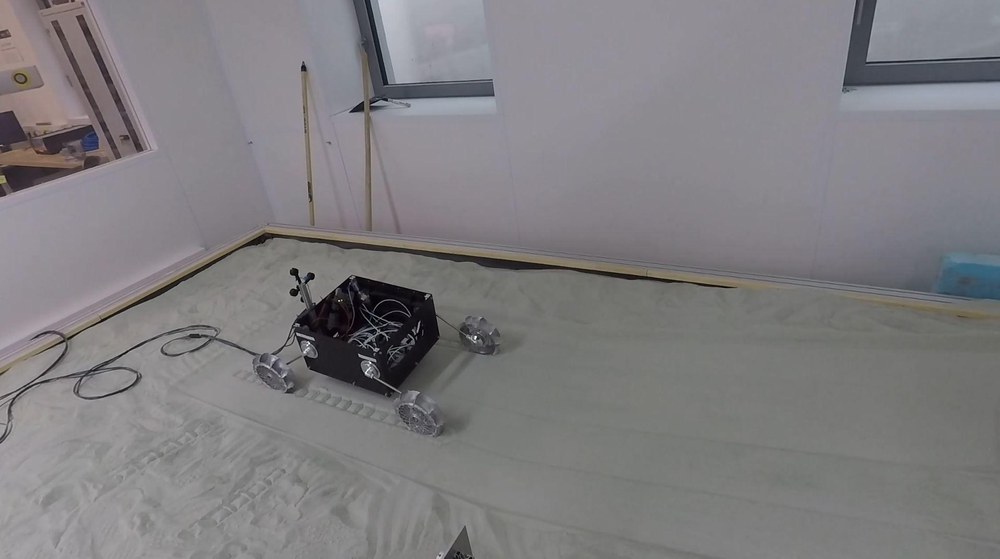

The new wheel design had to prove that it was up to the task in numerous virtual and real tests on the fully automated Terramechanics Robotics Locomotion Lab (TROLL) wheel test stand. In the future, many open questions about locomotion could be clarified using similar simulations, and the rover could be virtually tested in advance for operations under low gravity conditions – an environmental condition that cannot otherwise be recreated on Earth.

MMX – Martian Moons eXploration

MMX is a mission of the Japanese space agency JAXA with contributions from NASA, ESA, CNES (the French space agency) and DLR. CNES (Centre National d'Études Spatiales) and the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) are jointly contributing a 25-kilogram rover to the Martian Moons eXploration Mission (MMX). The Franco-German MMX rover is being designed and built under the joint leadership of CNES and DLR. In particular, DLR is responsible for the development of the rover's landing gear, including the lightweight body, as well as the entire uprighting and locomotion system. DLR is also contributing the connection adapter to the MMX spacecraft and providing a Raman spectrometer and a radiometer as scientific experiments. These will analyse the surface composition and texture on Phobos. CNES is making significant contributions with camera systems for spatial orientation and exploration on the surface, as well as for the study of mechanical soil properties. CNES is also developing the rover's central service module, including the on-board computer and the power and communications system. After the launch of the MMX mission, the rover will be operated by CNES control centres in Toulouse (France) and DLR in Cologne (Germany).

For DLR, the institutes of System Dynamics and Control, Composite Structures and Adaptive Systems, of Space Systems, of Optical Sensor Systems, of Planetary Research, for Software Technology and the Microgravity User Support Center (MUSC) are also involved under the leadership of the DLR Institute of Robotics and Mechatronics.

The MMX mission is a continuation of an already long-standing successful cooperation between JAXA, CNES and DLR. It builds on the previous mission Hayabusa2, in which JAXA sent a spacecraft to the asteroid Ryugu with the German-French MASCOT lander on board. On 3 October 2018, MASCOT landed on Ryugu and sent spectacular images of a landscape ridden with boulders and rocks, and virtually no dust. Hayabusa2 collected samples from Ryugu and brought them to Earth on 6 December 2020.