The new DLR short-arm centrifuge in :envihab

Time-lapse video of the installation of the short-arm centrifuge:

Your consent to the storage of data ('cookies') is required for the playback of this video on Youtube.com. You can view and change your current data storage settings at any time under privacy.

The steps were:

The centrifuge hall has been prepared so that the articulated lorry bearing the separate components of the short arm centrifuge can access it directly.

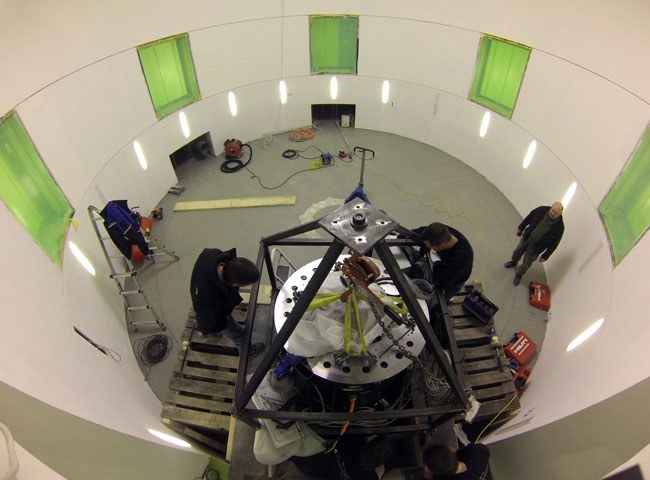

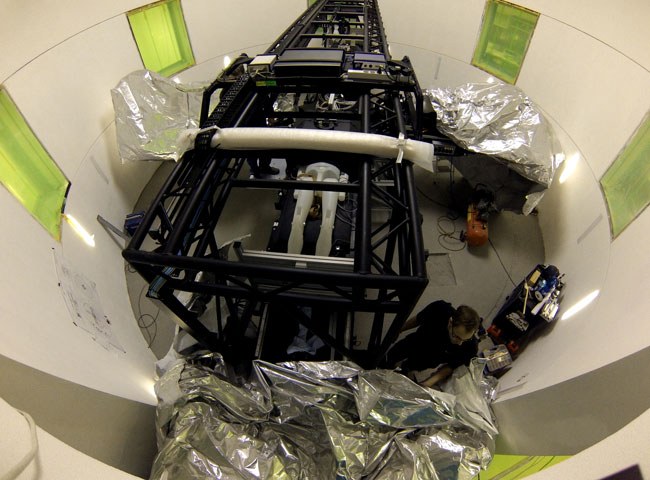

The pedestal has to be lowered into place using a cable hoist due to the difference in height between the centrifuge hall and the corridor.

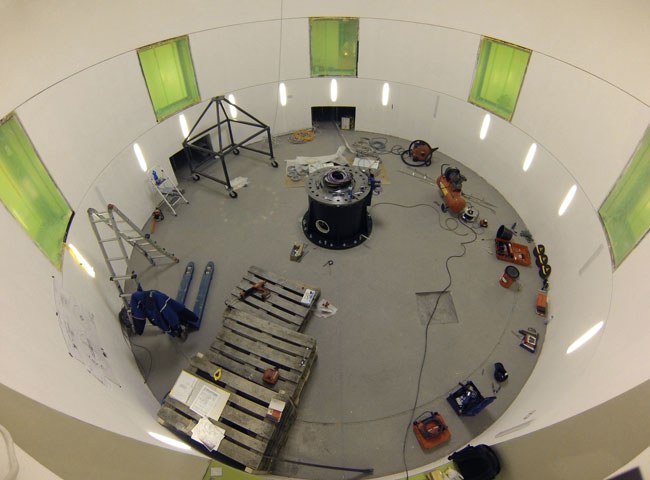

The site for the pedestal is prepared in the centre of the hall. Specialists from Austrian manufacturer AMST are in charge of the installation work.

Bolts are used to firmly attach the pedestal to the foundation, a floating concrete slab. The centrifuge's water-cooled motor is located inside the base.

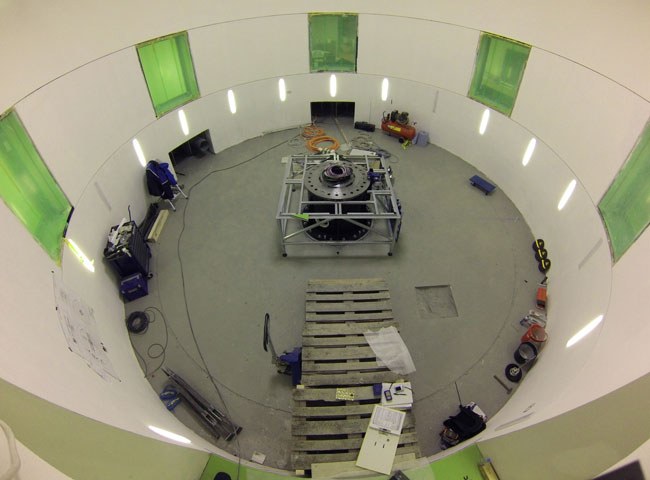

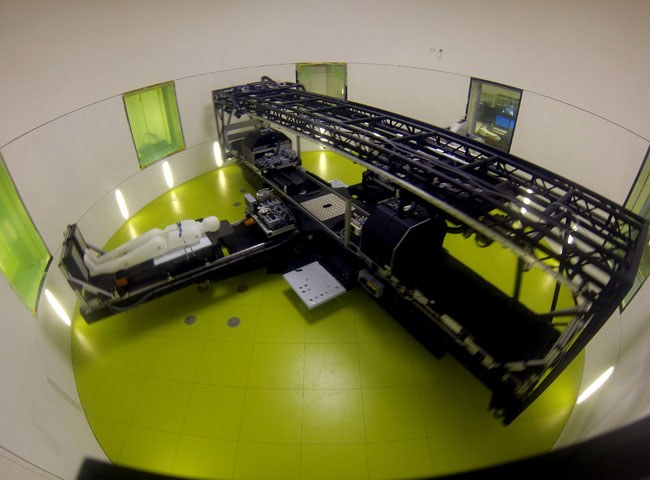

The assembly table is built around the pedestal. This construction will be secured to the raised floor.

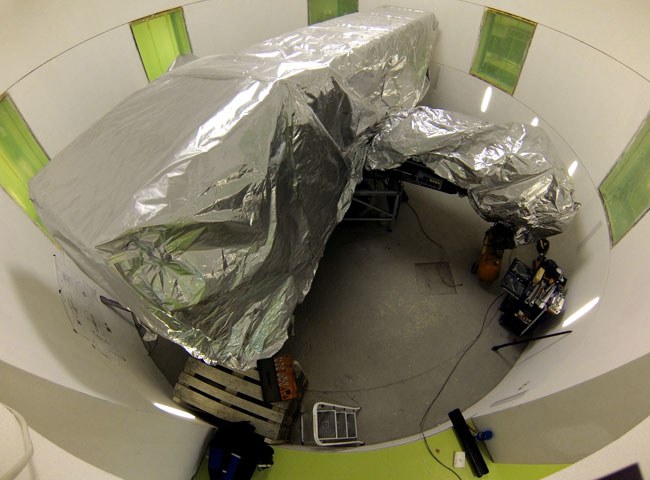

The main arm of the centrifuge is brought into the hall. A cover protects the integrated electronics and mechanisms against dust and prevents damage during transportation.

The main arm – 7.4 metres long in total – is in position in the hall, completely filling the picture. The centrifuge can generate forces of up to six times the force of gravity at the ends of the arm.

The three-metre side arm is attached to the main arm of the centrifuge. Designing the main motor as a torque motor enables the smooth operation of the centrifuge.

The protective cover is removed from the research instruments so all the necessary cable connections can be assembled.

Installation of the 'heart of :envihab' is complete. Initial tests will take place following the opening of :envihab on 5 July 2013.

All images are also available in the DLR Flickr photo stream.

The video is available for download in the Multimedia section.

All images: DLR/Fabian Walker CC-BY 3.0.

Tags: