Department Experimental and numeric Methods

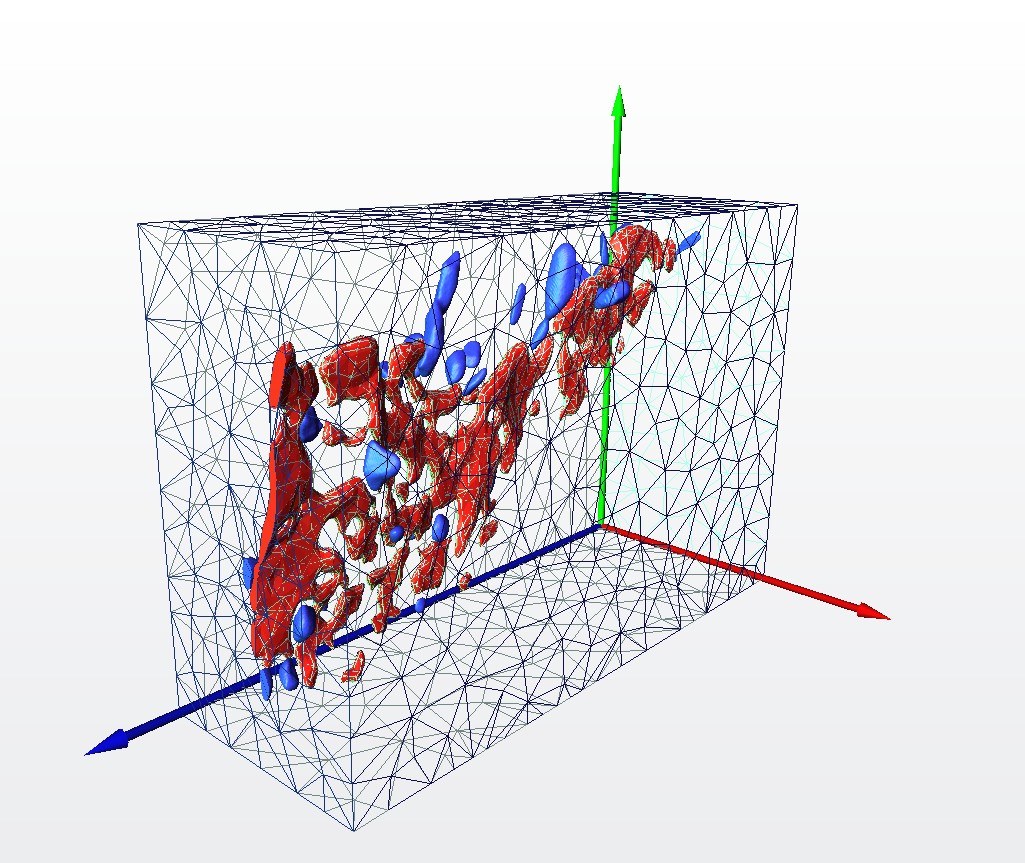

The Experimental and Numerical Methods department focuses on methods that are based on precise knowledge of material behavior under mechanical and thermal stress. The material behavior is influenced by material properties on different length scales. How a material behaves under stress is often determined at a microscopic level. The department therefore determines the characteristics of microstructures using 2- and 3-dimensional imaging methods and develops microstructure-based numerical models based on this data.

Existing parameters determine the prediction of material behavior

Another necessary ingredient for predicting material behavior with such models are the constitutive material laws of the structural components. In the simplest case, the elastic modulus must be known. Depending on the stress, however, many other parameters must be present, with which, for example, the plastic deformation behavior at high temperatures can be described. The numerical models are evaluated in validation experiments, which are validated via simulation calculations.

When it comes to materials for highly stressed components such as turbine blades in engines, complex test facilities are set up to validate the material models for operational stresses. One example is the test facility for thermomechanical stress in controlled temperature gradients (Thermal Gradient Mechanical Fatigue, TGMF).

The research and development work is carried out in close cooperation with the specialist departments of the institutes for materials research and construction methods and structural technology as well as within the framework of projects with partners from industry, medium-sized companies, research institutions and universities.

Projects:

- High-temperature fatigue in the DFG Collaborative Research Center TR130 'From Atom to Turbine Blade'

- Modeling and simulation of TiAl materials in cooperation with industrial partners

- Characterization of high-temperature materials using high-energy synchrotron X-rays in cooperation with the Embry-Riddle Aeronautical University, FL, USA and the Argonne National Laboratory, Il, USA

If you would like to find out more about our work, please do not hesitate to contact us. We offer the following services, among others:

- Joint application and implementation of publicly funded projects

- Advice and implementation of research work on behalf of the company

- Promotion of young scientists, supervision of bachelor's, master's and doctoral theses, postdoctoral training