Department Thermoelectric Materials and Systems

Optimized use of thermoelectric materials and modules

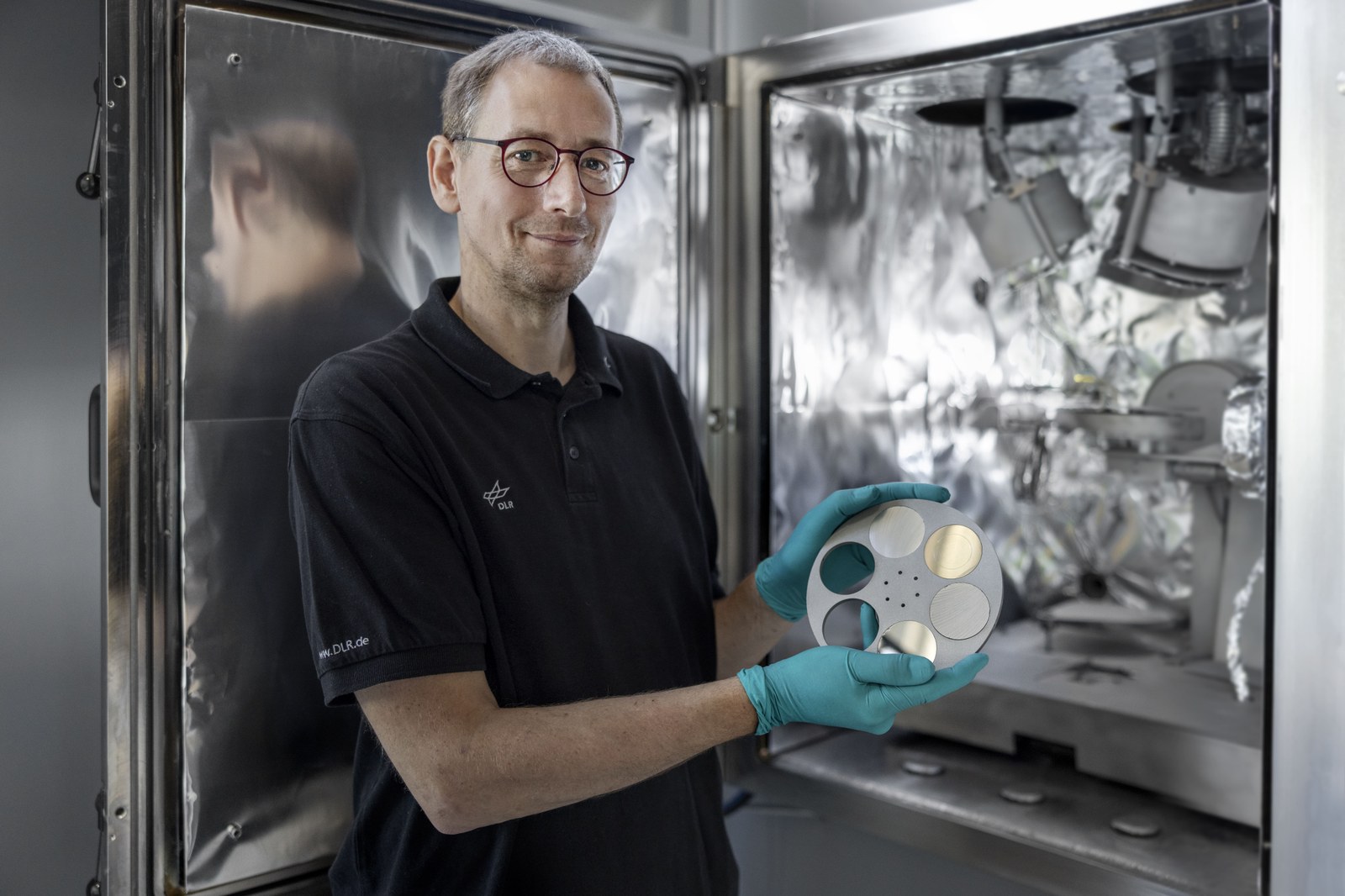

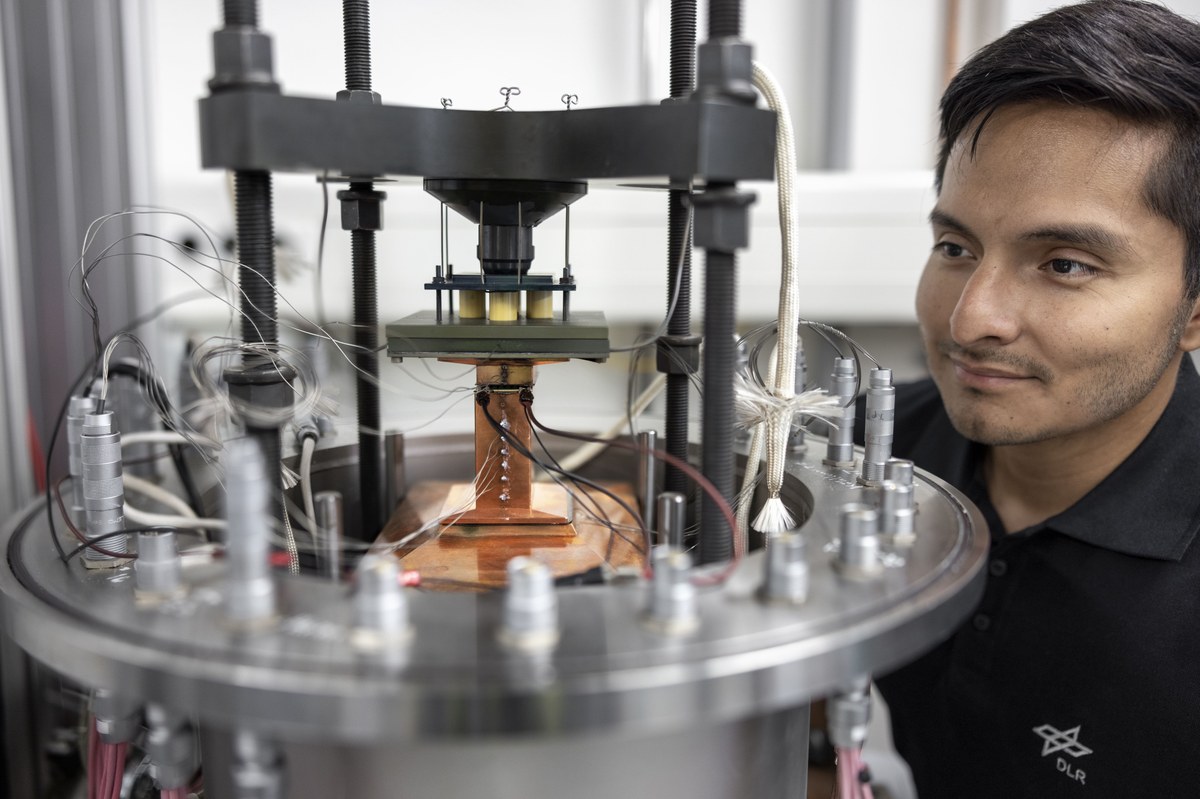

For optimal use, thermoelectric (TE) materials and modules must be adapted to the requirements of the system where they are integrated. Depending on the temperature range of the application, a spectrum of different TE materials is available for choice. We study and engineer such materials to build high-performance and long-term stable TE modules for low to high temperature ranges. We consider all process steps from material, device and system simulation through material synthesis to construction and joining technology for TE modules and the development of unique measurement methods for TE materials and modules. These steps are steadily accompanied by experimental determination of the TE properties (Seebeck coefficient, electrical and thermal conductivity; bulk and spatially resolved) and microstructure (chemical and phase composition, crystal defects), which serve to evaluate the material performance and provide a basis for the simulation and optimization of TE modules under various operating conditions.

A heat to electrical energy conversion efficiency of 8-10% was achieved with thermoelectric modules

Having the aforementioned comprehensive spectrum of competences available together in our institute accelerates the development of the individual process steps and enables transparent and efficient progress on the way to powerful, stable and sustainable thermoelectric generator (TEG) modules for efficient energy use in the future. Using and developing methods applicable in industry, prototype TE modules that achieve 8-10% conversion efficiency have already been built and can be manufactured in small numbers as prototype series. Such modules were used, e.g., in the ZIM project “nano-BHKW” to equip a gas condensing boiler with TEG to create a small-scale combined heat and power system (CHP) for family homes. Likewise, TEG modules can be used in mobiles (e.g., e-fuel trucks), in energy-intensive industrial processes (metal smelting, rolling and casting), and in the evaporation of cryogenic fuels (at LNG terminals) or in electric flight (temperature control and waste heat utilization at fuel cells and H2-fueled jet engines).

Alongside renewable energy sources, integrated CHP systems, leveraging waste heat and process-related thermal flows via TEG, stand out as a pivotal element in contemporary energy frameworks. These systems, as manageable power producers, provide:

- Supply stability

- Storage options

- Self-sufficiency

- Optimized efficiency by converting waste heat into electrical energy

We develop TEG modules as the core component of such heat-to-electricity converters for manifold operating conditions and application scenarios.

By integrating TEG into industrial plants, vehicles or further systems that release waste heat, companies and organizations can contribute to energy efficiency, self-supply, enhanced safety and reliability but also added functionality of systems.

TEG technology enables the conversion of unused heat loss into electrical energy and thus a reduction in overall energy consumption.

Using waste heat through thermoelectric generators

The advantage of converting waste heat through TEG is additional power generation without additional fuel costs or environmental impact.

This sustainable approach holds promise for enhancing overall energy system efficiency while mitigating environmental impact. Because of the limited efficiency of TEG thus far, their widespread industrial adoption has been hindered. However, TE products have found their niche, particularly in facilitating additional system functionalities such as decentralized energy supply and self-sufficient sensors, structural health monitoring (SHM) at machine components that are in continuous motion or rotation. Surmounting economic barriers often proves easier in such cases rather than when incentivized solely by the amount of regeneratively produced electrical energy.

Furthermore, TEG serve as autonomous and mobile power sources. They are used as Radioisotope Thermoelectric Generators (RTG) for space exploration, Auxiliary Power Units (APU) for military applications, navigation land- and seamarks, mobile and temporary electricity supply during large-scale events, disaster remediation efforts, and aid initiatives in developing countries, as well as for outdoor and leisure.

Autonomous sensor technology

The implementation of self-sufficient sensor nodes powered by TEG opens up interesting opportunities for self-sufficient measurement, control and information technology. The advantages are manifold:

- Independent power supply: Self-sufficient sensors powered by TEG are independent of additional power sources. This increases flexibility in the placement of sensors as they are completely free of maintenance, making them suitable for long-term operation at remote or unaccessible locations.

- Long-term monitoring: Self-sufficient sensors can be used for long-term monitoring without the need for periodic battery change or external power supply. This is particularly relevant in remote areas and in sensitive applications that require persistent monitoring.

- Environmental friendliness: Using waste heat or ambient heat to generate electricity is environmentally friendly and helps optimize energy consumption and reduce carbon footprint.

- Various applications : Self-sufficient sensors with TEG can be used in various industries such as environmental monitoring, industrial automation, agriculture, automotive technology, aircraft and satellites and many others where high reliability and stability are important.

Would you like to know more about our work or thermoelectrics in general? Do not hesitate to contact us!